This document continues from Part I and focuses on installation requirements for Pitot tube flowmeters in gas and steam pipelines. Proper installation is essential to ensure reliable measurement and avoid common issues such as zero drift, oscillation, and excessive deviation.

3. Installation in Gas Pipelines

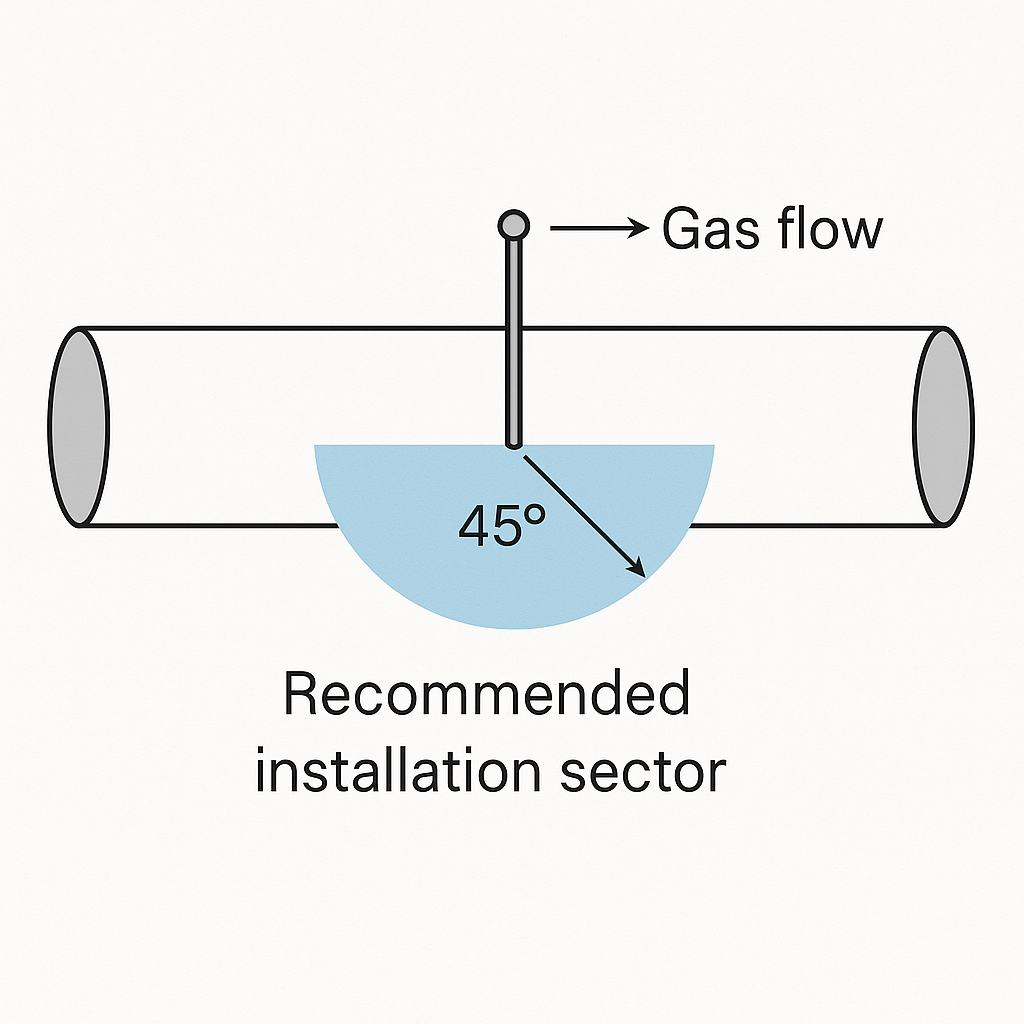

Optimal Position in Horizontal Pipes

When gas flows through horizontal pipelines, condensate or heavy impurities tend to accumulate at the bottom.

Recommended region: The detection rod should be installed in the 0°–45° sector below the horizontal centerline (some standards allow ±45°, but the lower sector is preferred).

Reasoning:

Bottom liquid or impurities can block pressure ports if installed at 90°–180°.

The 0°–45° lower sector provides a more stable and homogeneous gas phase, ensuring that pressure ports capture representative velocity.

Vertical Pipe Considerations

The probe should be inserted radially into the pipe center, avoiding boundary layers with low velocity.

Additional Requirements

Anti-condensation: For humid gases (e.g., saturated vapor), impulse lines must be heated/insulated to prevent liquid column formation.

Leak tightness: After installation, use soap solution to check the sealing of pressure ports, preventing external air ingress and measurement errors.

4. Installation in Steam Pipelines

Steam, whether dry or wet, is a special medium due to high temperature and potential phase change. Its installation requirements differ significantly from liquids and general gases.

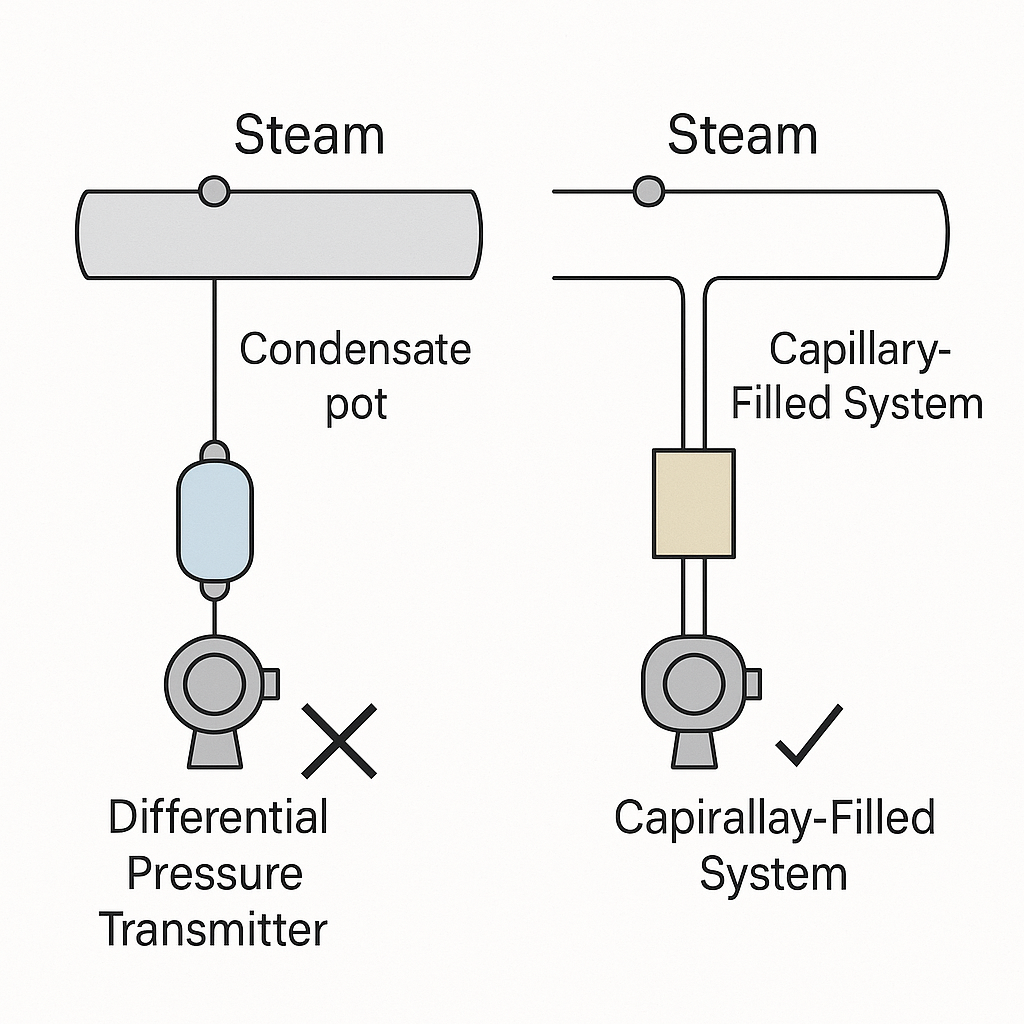

(1) Dry Steam (x ≥ 0.95)

Challenges: High temperature, phase stability, and avoiding false differential pressure signals.

Core Principle: Do not use condensate pots

Density mismatch: Water column density is hundreds of times higher than steam; using condensate distorts the signal.

Zero drift risk: Unequal liquid column heights or temperature differences lead to unstable static pressure offsets.

Response delay: Large water columns increase system inertia, slowing response to flow changes.

Recommended Solution: High-temperature transmitter with filled capillary system

Equipment: High-temperature differential pressure transmitter (≥300 °C tolerance with heat sinks or special alloys).

Transmission medium: Capillaries filled with stable high-viscosity silicone oil (≥500 cSt).

Benefits: Consistent density, stable zero point, and reliable calibration compensation.

Installation details:

Capillaries ≤3 m, straight and without U-bends.

Transmitter mounted above tapping points to reduce oil backflow.

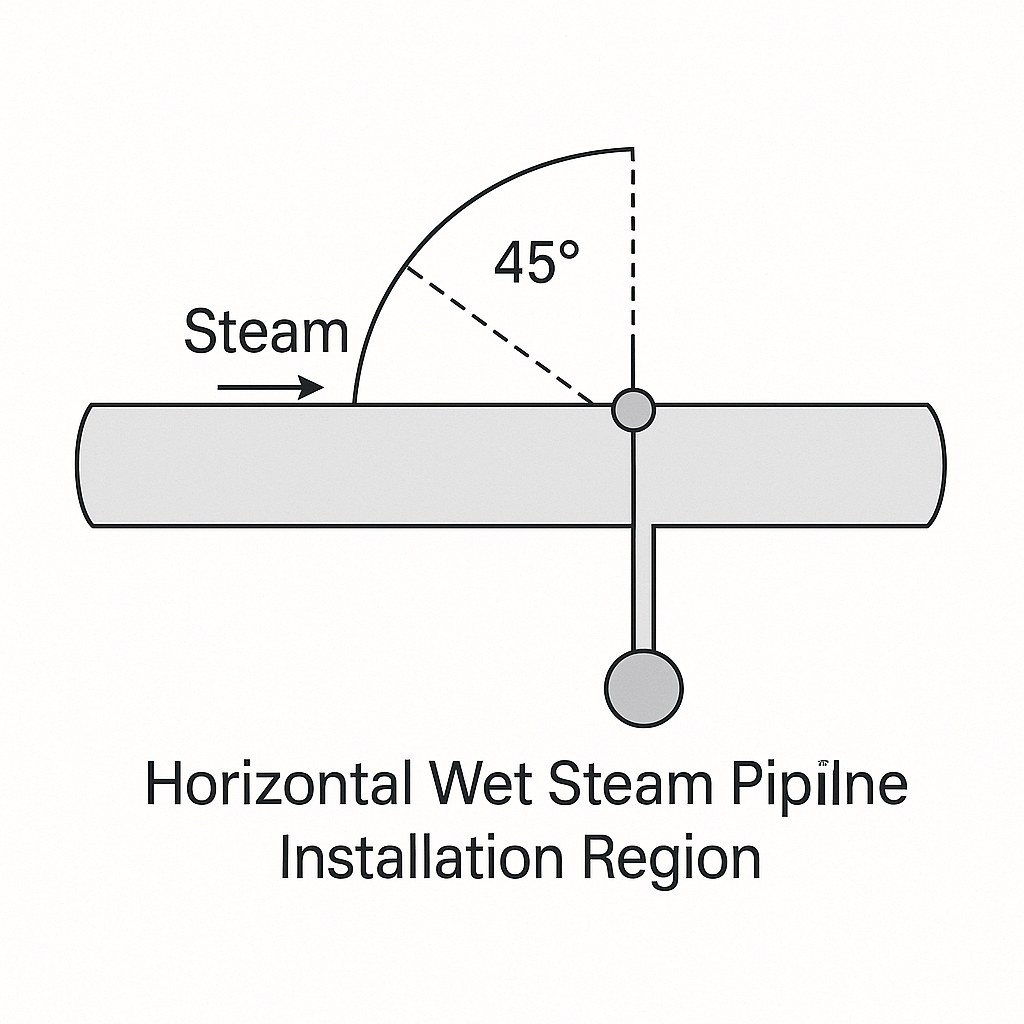

(2) Wet Steam (x < 0.95)

Wet steam contains suspended droplets, making it a typical two-phase flow. The main challenges are liquid accumulation at the bottom and droplet impact on pressure ports.

Installation Positions

Horizontal pipelines: Install probe at the upper-side 45° region to avoid droplet impingement and bottom liquid accumulation.

Vertical pipelines: Applicable only for upward flow; probe must be at the center to avoid the wall liquid film zone.

Engineering Measures

Pressure ports:

Anti-erosion design (conical or recessed ports).

T-shaped slot (width-to-depth ratio ≥5) to prevent blockage.

Back-flushing interface for inert gas purging (≈10 s per shift).

Impulse lines: Inclined downward by 10° to slow droplet ingress and reduce clogging.

Condensate management: Install a collection pot at 1D downstream; discharge via automatic or manual valves.

Differential pressure system: Dual capillaries filled with silicone oil; transmitter diaphragm coated with hydrophobic nanolayer to reduce droplet adhesion.

Dynamic compensation: Implement signal filtering (e.g., wavelet denoising) and integrate online steam dryness data to correct flow coefficients.