1. Common Pitfalls in Piping Installation

Piping installation is often perceived as a routine task in industrial projects. However, even minor mistakes can lead to catastrophic system failures. Based on years of field experience, here are six common issues encountered during piping installation:

1.1 Poor Interpretation of Drawings and Improper Fit-Up

In many projects, construction teams fail to thoroughly review engineering drawings, assuming “pipes are simple.” This can lead to misaligned equipment connections, incorrect support base placements, or even the use of wrong pipe diameters. A more severe case occurs when design changes are communicated verbally without updating the drawings, resulting in large sections requiring rework.

Lesson Learned:

Always review and understand drawings in detail.

Verify critical points on-site, such as equipment interfaces, elevations, and support locations.

Ensure that all design changes are documented and reflected in updated drawings.

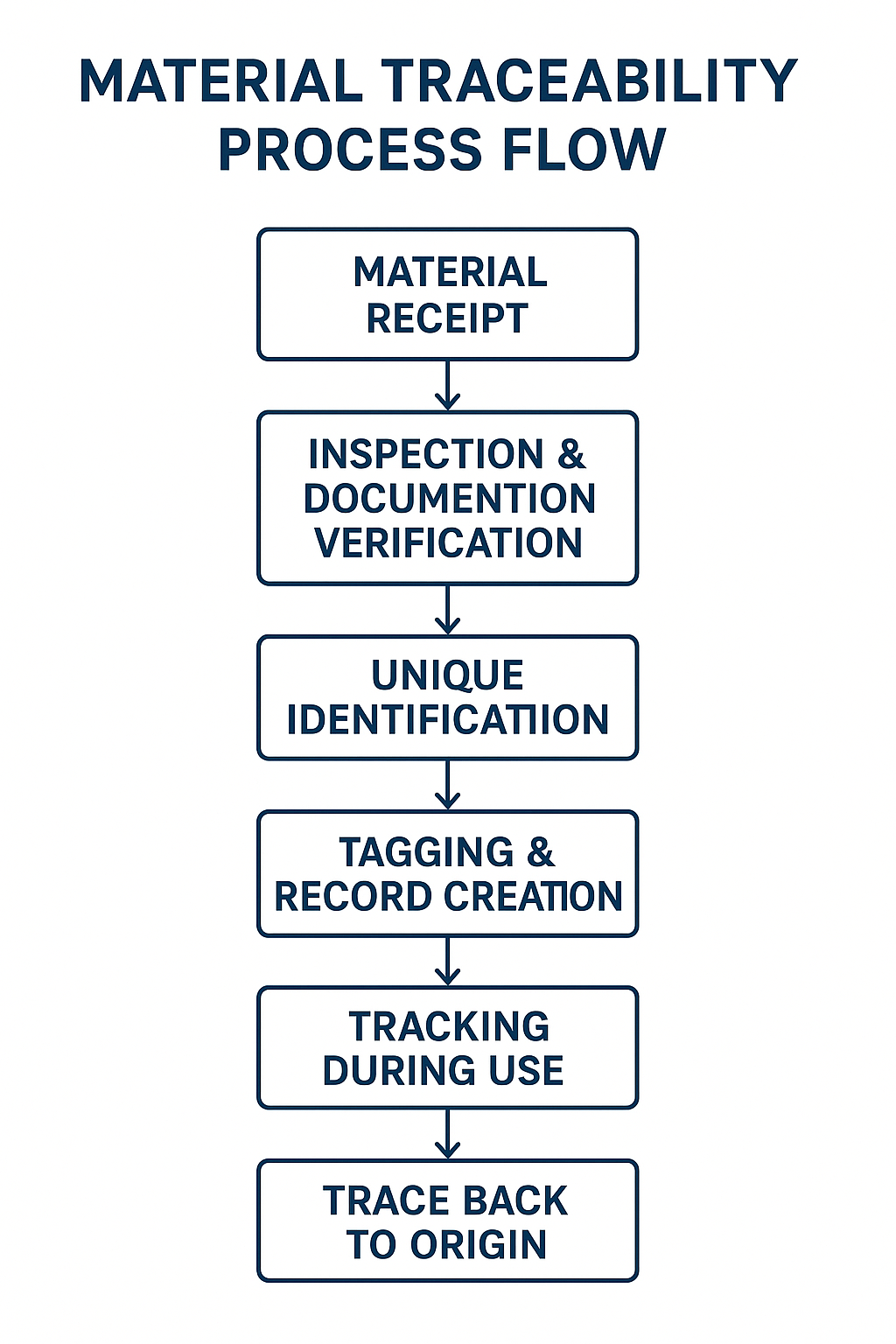

1.2 Inadequate Material Management and Traceability

Mixing different grades and materials (e.g., carbon steel flanges in stainless steel pipelines) is a serious risk. In one instance, a high-pressure system nearly failed due to an unmarked carbon steel flange being used in a stainless steel line.

Lesson Learned:

Implement a material tracking system from arrival to installation.

Maintain clear identification and segregation of materials (carbon steel, stainless steel, alloy steel).

Perform pressure and sealing tests for all valves; reject non-conforming items.

1.3 Inaccurate Cutting and Assembly Errors

Errors in prefabrication shops, such as pipes cut too short or too long, can cause misalignment during site assembly. Improper cleaning of weld surfaces and misaligned flanges often result in leakage.

Lesson Learned:

Use CNC cutting for precise prefabrication.

Clean flange faces before assembly; use feeler gauges to check parallelism.

Preassemble complex sections in the shop and conduct trial fitting on-site.

1.4 Poor Support Installation and Thermal Expansion Issues

Skipping guide supports or neglecting fixed points near expansion joints leads to significant thermal displacement. In one case, thermal expansion caused the pipe to buckle and damaged adjacent equipment.

Lesson Learned:

Follow support drawings strictly; ensure proper spacing and consider thermal movement.

Use pre-stretching or pre-compression techniques for high-temperature pipelines.

Apply insulation where necessary to prevent heat-related issues.

1.5 Non-Compliant Welding Practices

Allowing unqualified welders to perform tasks or ignoring the Welding Procedure Specification (WPS) results in substandard joints. Common issues include incorrect parameters, lack of post-weld cleaning, and insufficient inspections.

Lesson Learned:

Ensure all welders are certified and qualified for the job.

Control welding parameters as per approved WPS.

Conduct non-destructive testing (NDT) for critical welds (e.g., RT or UT inspections).

1.6 Poor Labeling and Incomplete Records

Lack of flow direction markings and pipe size labels creates confusion during operation. Missing records for buried pipelines and pressure tests make it impossible to trace issues later.

Lesson Learned:

Apply comprehensive labeling (flow direction, media, size, identification numbers).

Archive all test records, inspection reports, and as-built documentation.

Take photos of critical and buried sections before backfilling.

2. Best Practices to Prevent Failures

To ensure the highest quality and reliability in piping systems, adopt the following best practices:

2.1 Comprehensive Pre-Construction Meetings

Organize joint review meetings involving designers, owners, and contractors.

Address critical aspects such as interfaces, routing, and support placement.

Ensure all changes are managed with a clear authorization and documentation process.

2.2 Layered Material Inspection and Closed-Loop Management

First-level: Crew inspects appearance and quantity.

Second-level: Project team verifies certificates and specifications.

Third-level: Third-party or supervisory inspection.

Implement a unique ID system for all materials to ensure traceability.

2.3 Standardized Prefabrication and Trial Assembly

Equip workshops with automated cutting and beveling machines.

Clean and align components before assembly.

Control flange face gaps within 0.8 mm; conduct trial assembly of complex spools.

2.4 Precise Support Installation and Thermal Compensation

Position supports, anchors, and guides exactly per drawings.

Consider thermal expansion during installation; pre-stress as required.

Provide insulation and vibration dampers where needed.

2.5 Strict Welding Discipline and Quality Control

Verify welder qualifications.

Follow approved WPS parameters strictly.

Perform NDT for all critical joints; repair defects immediately.

2.6 Complete Labeling and Documentation

Ensure every pipe section is labeled with flow direction, media, size, and tag number.

Archive logs for pressure testing, flushing, and NDT.

Take photos of concealed works for future reference.

2.7 Continuous Training and Accountability

Provide ongoing technical training, especially on updated codes and lessons learned.

Assign responsibility to individuals for each task.

Encourage a culture of accountability and reward excellence.

3. Conclusion: Why Every Detail Matters

The greatest lesson from years of field experience is that there are no small issues in piping installation. A single misaligned flange or overlooked support can escalate into system-wide failures. Quality piping installation is not about doing more but about doing every step right.

Remember: “The shortcuts you take today will come back to haunt the system tomorrow.”

By fostering a culture of professionalism and meticulous attention to detail, we can ensure that every installation delivers the reliability and performance our clients expect.