Introduction

In mineral processing plants, flotation tanks are large vessels where slurry and froth separation takes place. At first glance, the control of liquid level in such large tanks seems to require long filling times and correspondingly large PID integral times. However, this intuitive assumption may lead to incorrect parameter settings. This document presents a case study showing why the effective filling time of a flotation tank can be surprisingly short, and how this affects PID parameter tuning.

Misconception: Large Tank = Long Integral Time

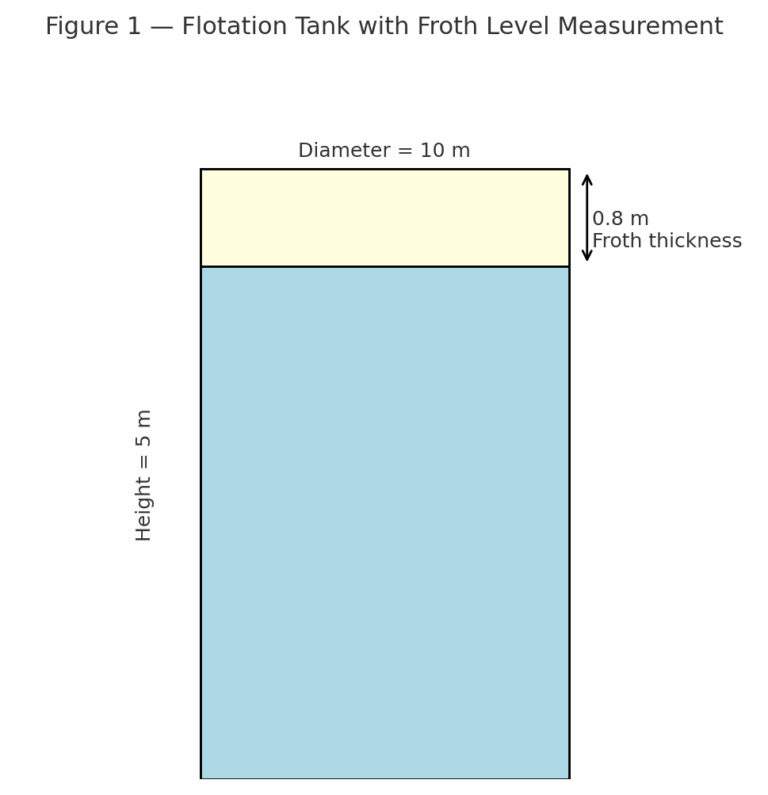

A flotation tank with a diameter of 10 m and a height of 5 m looks massive, and one might assume the level control would require integral times of 10 minutes or more. In practice, this assumption can be misleading because:

The measured variable is not the full tank level, but rather the froth layer thickness, with an effective range of only about 0.8 m.

The throughput flow rate is very high, while the valve openings are relatively small.

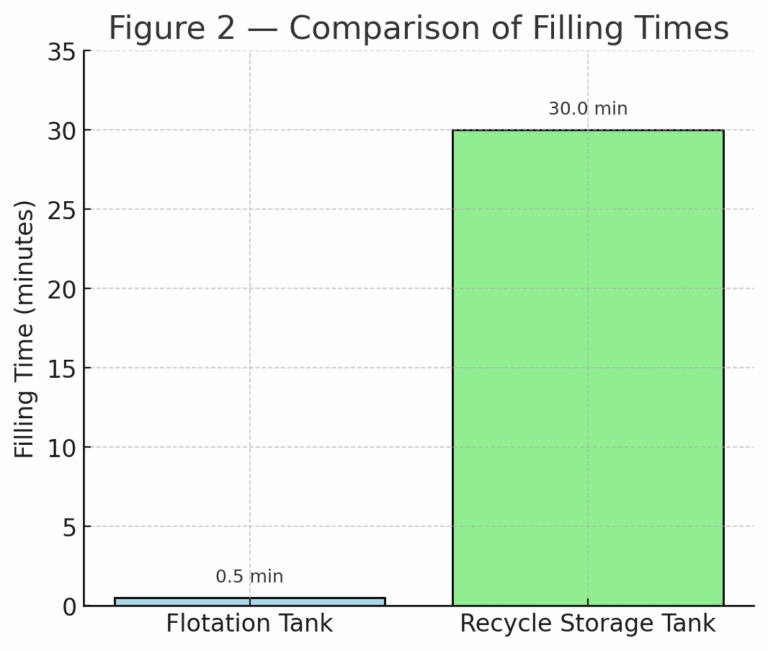

As a result, although the vessel volume looks huge, the actual effective filling time is only about 30 seconds. By contrast, typical recycle storage tanks often have filling times of 30 minutes or more.

Practical Considerations for PID Tuning

Because the effective filling time is short, one cannot simply assign a fixed set of PID parameters for “all large tanks.” Instead:

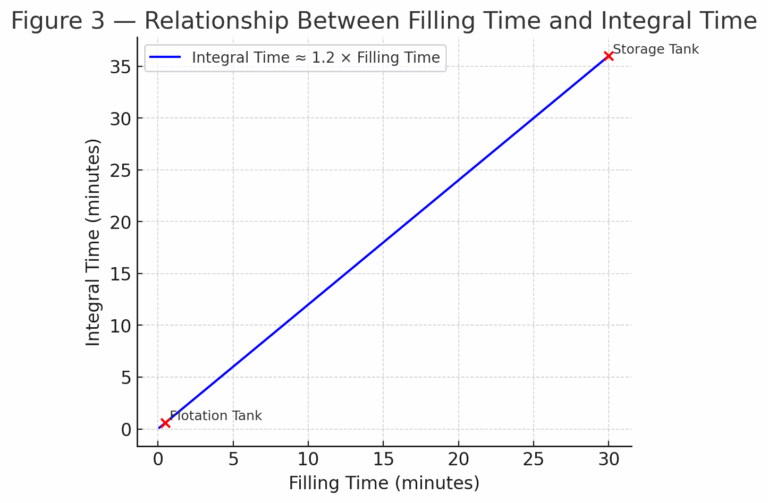

The integral time should be selected in relation to the filling time, not the physical size of the vessel.

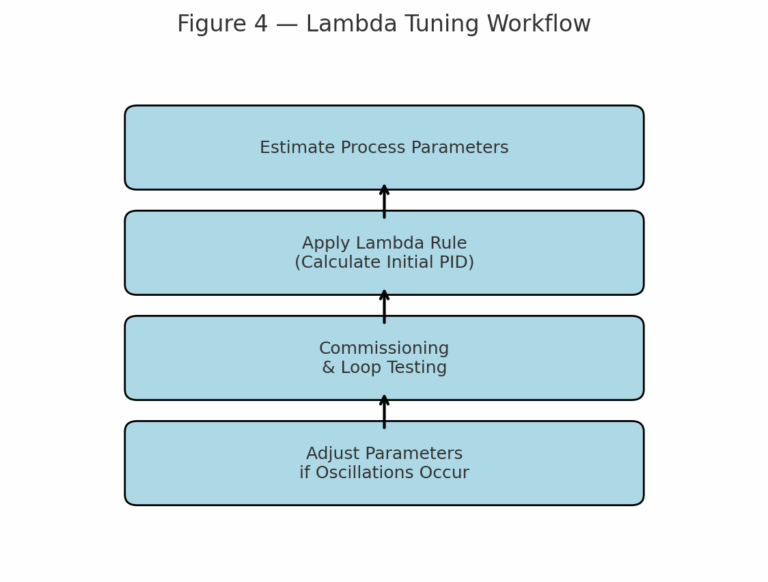

Initial PID parameters for integrating-level processes can be estimated using design-based formulas, essentially following the Lambda tuning method. These estimates serve as starting values, to be fine-tuned during commissioning.

If oscillations appear during startup, the first step is to reduce proportional gain and re-test.

Hidden Condition: Small Dead Time

The proposed initial estimation approach assumes the process dead time is relatively small. If strong oscillations occur in-phase with process dynamics, this may indicate:

Upstream disturbances are dominating, or

Proportional action is too aggressive.

In such cases, re-selecting a smaller proportional gain and re-validating the loop is recommended.

Conclusion

The flotation tank case demonstrates that appearances can be deceiving: a vessel that looks massive may actually require relatively short integral times. The key lesson is that PID parameter tuning must be based on effective process dynamics, not equipment size. Lambda tuning provides a reliable starting point, while practical adjustments during commissioning ensure stable operation.