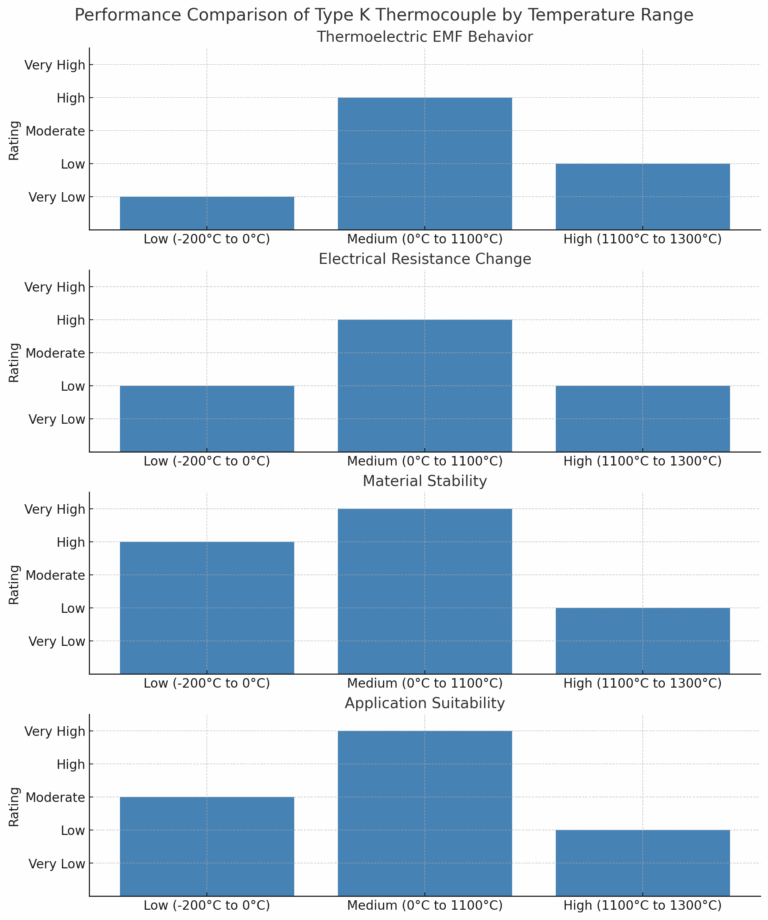

🔹 1. Low Temperature Range (−200°C to 0°C)

• Electron Migration is Suppressed

At cryogenic temperatures, atomic thermal motion weakens, reducing the ease of electron migration from the Nickel-Chromium leg to the Nickel-Silicon leg. This leads to lower thermoelectric EMF output and reduced sensitivity.

• Increased Electrical Resistance

As temperature decreases, the electrical resistance of both alloys increases, following typical metallic behavior. This change in resistance can be used for indirect temperature estimation, though with limited sensitivity.

• Stable Material Characteristics

In this range, the crystalline structures of both alloys remain stable, minimizing interference from environmental factors. Type K thermocouples maintain functional integrity and reliability under these conditions.

🔸 2. Medium Temperature Range (0°C to 1100°C)

• Excellent Linearity of EMF Output

As temperature rises, electron mobility increases, resulting in a strong and predictable thermoelectric response. The EMF vs. temperature curve in this range is nearly linear, making Type K thermocouples highly sensitive and accurate.

• Linear Increase in Resistance

Thermal vibrations of atoms cause increased electron scattering, leading to linear resistance growth with temperature. This consistent change supports precise electronic temperature signal conversion.

• Stable Long-Term Performance

The oxidation resistance of Chromel and thermal stability of Alumel allow the thermocouple to function reliably for extended periods, ensuring consistent and repeatable measurements in this working range.

🔺 3. High Temperature Range (1100°C to 1300°C)

• Complex EMF Behavior

At elevated temperatures, accelerated oxidation of chromium in the Chromel leg forms surface oxide layers that hinder electron transport. This results in non-linear or erratic EMF output, affecting measurement accuracy.

• Abnormal Resistance Behavior

Microstructural changes such as grain growth and lattice distortion may occur at these temperatures. These phenomena disrupt the linear relationship between temperature and resistance, complicating calibration and interpretation.

• Mechanical and Thermal Stress

Due to differing thermal expansion coefficients, internal stress may develop within the thermocouple junction. This can lead to deformation, cracking, or failure, ultimately impacting service life and precision.

✅ Conclusion & Application Tip

Type K thermocouples are ideal for a wide range of applications, especially in medium-temperature industrial environments due to their reliability and linear response. However, in cryogenic or extreme high-temperature conditions, users should consider potential limitations in sensitivity, linearity, and mechanical integrity. In such cases, alternative types like Type T (for low temperature) or Type N (for high temperature stability) may offer better performance.