1. General Concept of DCS System

A Distributed Control System (DCS) is a computer-based control system used for industrial process automation. It combines distributed control units (at the field level) with a centralized operation and monitoring system (at the upper level) to achieve real-time measurement, control, alarm handling, trend analysis, and management of production processes. DCS systems are widely used in industries such as:

Chemical and Petrochemical

Power Generation and Metallurgy

Pharmaceuticals and Pulp & Paper

Water Treatment and other Process Industries

2. General Layout of the DCS System

A DCS system typically adopts a layered, distributed architecture, generally consisting of the following four levels:

| Level | Name | Main Equipment | Function |

|---|---|---|---|

| Level 1 | Field Level | Field Instruments, Actuators, Transmitters | Responsible for signal measurement and actuation (collecting data and controlling objects). |

| Level 2 | Control Level | Controllers, I/O Modules | Real-time signal collection, control algorithm execution (PID, logic, sequence control). |

| Level 3 | Operation Level | Operator Stations (HMI), Engineering Stations | Process monitoring, control, alarming, configuration, and historical trend analysis. |

| Level 4 | Management Level | Data Servers, MES Interface, Database | Production data management, report generation, communication with upper-level systems (ERP, MES). |

3. Detailed Explanation of Each Part of the DCS System

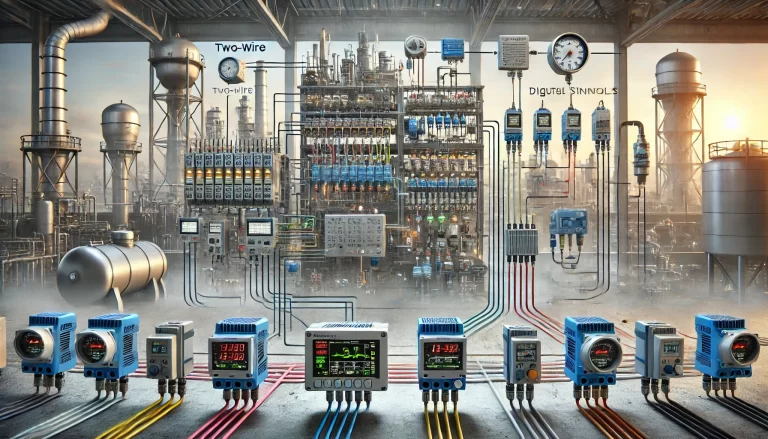

3.1 Field Level

Main Equipment:

Sensors and Transmitters (for pressure, temperature, flow, level, etc.)

Actuators (electric valves, control valves, variable frequency drives, motors)

Function:

Convert physical quantities (such as pressure and temperature) into standard signals (4-20mA, 0-10V, digital signals).

Receive control commands from the system and execute corresponding actions.

Communication:

Communicates with I/O modules via field buses (e.g., Foundation Fieldbus, Profibus, HART, Modbus).

3.2 Control Level

Core Equipment:

Control Station: The “brain” of the system, executing control algorithms.

I/O Modules: Responsible for signal acquisition and output, including analog (AI, AO) and digital (DI, DO) inputs and outputs.

Function:

Receives field-level signals via I/O modules.

Executes control strategies such as PID, logical control, and interlock protection.

Outputs control results to actuators.

Communicates with upper-level systems to upload data and alarm statuses.

Features:

Distributed deployment: Each control station operates independently, with redundancy.

Dual-controller hot backup (primary/secondary) to improve reliability.

3.3 Operation Level

Main Equipment:

Operator Stations (OCS or HMI): Used for real-time display of process flow.

Engineering Stations (ES): Used for configuration of control strategies, graphics, and parameters.

Alarm and Trend Servers: Used for alarm handling and historical trend analysis.

Function:

Real-time display of process flow diagrams.

Monitors production parameters, alarms, and trends.

Engineering Stations for configuration (control strategy, graphical screens, parameters).

Operator Stations for operational control (start/stop, adjustments, alarm acknowledgment).

Communication:

Connected to the Control Level through a Control Network (typically industrial Ethernet or dedicated industrial buses).

Operator Stations and Engineering Stations are connected via a Plant LAN.

3.4 Management Level

Main Equipment:

Historical Data Servers (HIS)

Report and Analysis Servers

MES/ERP Interface Servers

Function:

Stores and analyzes historical data.

Generates production reports and trend analysis.

Provides production data to upper-level management systems (ERP, MES).

Supports system integration through interfaces such as OPC, Modbus TCP/IP, and database connections.

4. Typical DCS Network Architecture (Text-Based Description)

┌─────────────────────────────────────────────┐

│ Management Level │

│ Data Servers / MES / Report Analysis │

└──────────────────────┬────────────────────┘

│ Ethernet

┌──────────────────────┴────────────────────┐

│ Operation Level │

│ Engineering Stations, Operator Stations, │

│ Historical Servers, etc. │

└──────────────────────┬────────────────────┘

│ Control Network (Industrial Ethernet)

┌──────────────────────┴────────────────────┐

│ Control Level │

│ Controllers / I/O Cabinets (with CPU and │

│ I/O Modules) │

└──────────────────────┬────────────────────┘

│ Field Bus

┌──────────────────────┴────────────────────┐

│ Field Level │

│ Sensors, Transmitters, Valves, Actuators │

└────────────────────────────────────────────┘

5. Key Features and Advantages of DCS

| Feature | Explanation |

|---|---|

| Distributed Control, Centralized Management | Control tasks are delegated to field controllers, while monitoring is centralized in the upper system. |

| High Reliability | Redundant controllers, communication, and I/O modules ensure system reliability. |

| Scalability | Modular design supports system expansion and network interconnection. |

| Powerful Data Management | Real-time and historical data storage, trend analysis, and alarm management. |

| User-Friendly HMI | Graphical interfaces that make operations and maintenance intuitive and easy. |

6. Conclusion: Understanding DCS

In summary, a DCS system is analogous to a “neural network” in industrial processes:

Sensors and actuators act as the “nerve endings.”

Control stations are the “brain cortex.”

The Operation Level is the “central system.”

The Management Level serves as the “thought and decision-making layer.”

The entire system works synergistically to ensure the safe, stable, efficient, and visual control of industrial processes.