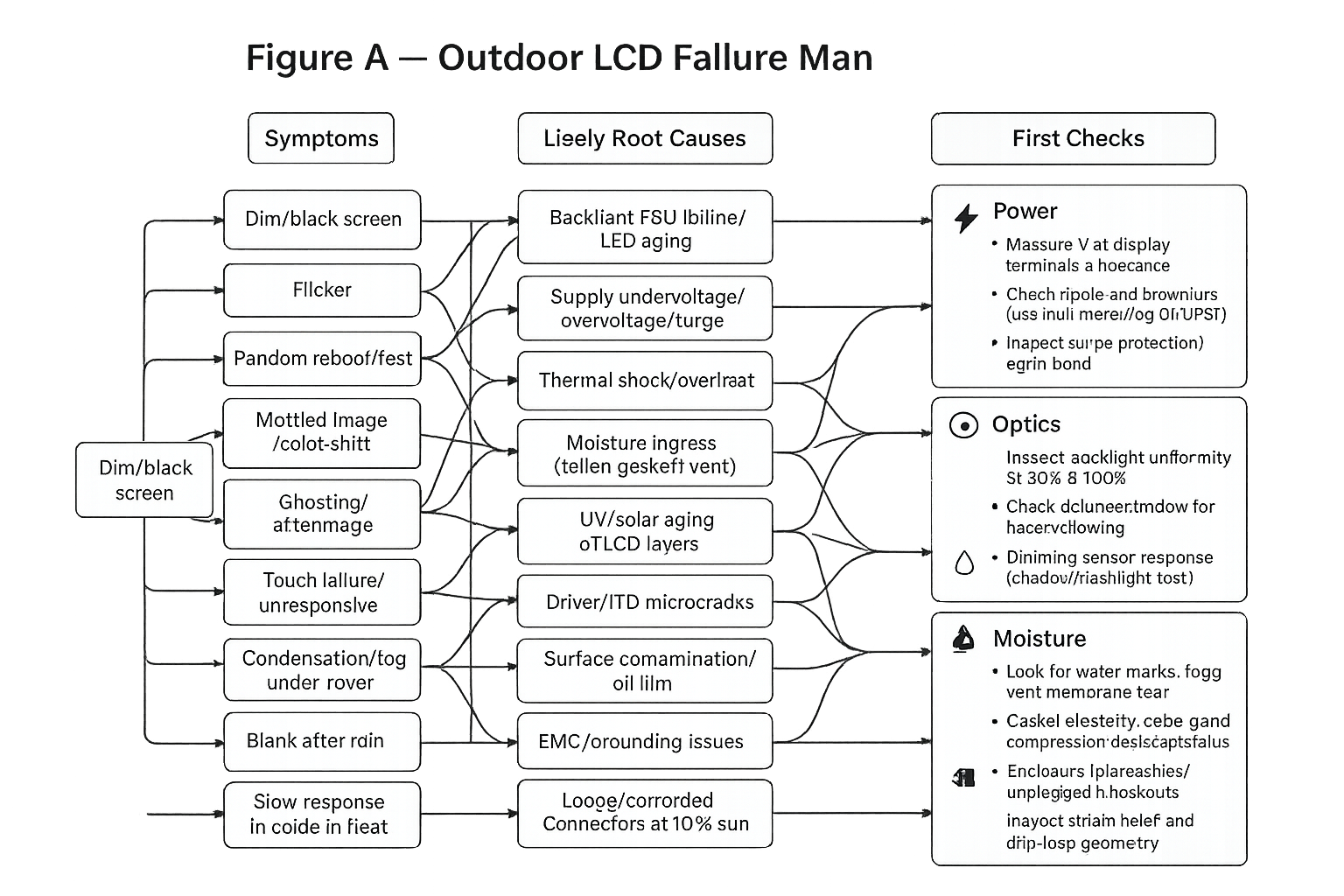

1) What goes wrong outdoors (quick symptoms → likely causes)

Dim/black screen, flicker → backlight PSU/LEDs aged or damp; supply fluctuation; thermal shock damage.

Condensation/fog under cover → low enclosure rating; cracked/aged sealant; water ingress.

Mottled image / color shift → LCD chemistry aged by heat/UV; driver IC faults.

Touch failure → oil/film on surface; ITO micro-cracks; moisture/dust shielding the capacitive field.

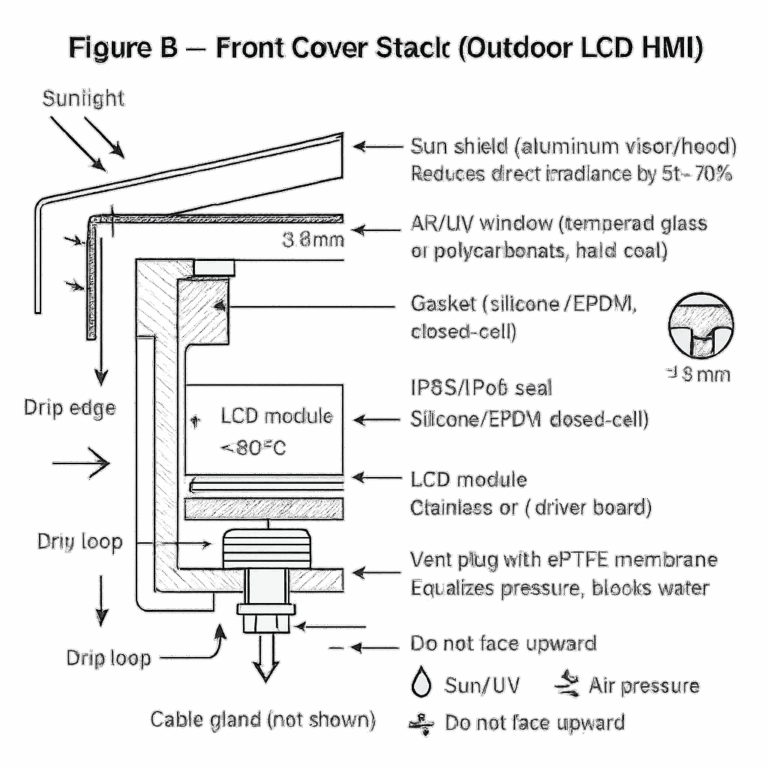

2) Design/selection measures (prevent problems up front)

Ingress & UV: Choose IP65+ outdoor-rated HMI displays with UV-resistant window and gasketing.

Wide temperature: Specify –30 °C to +70 °C (or better) display/driver components.

Sunlight readability: ≥ 800 cd/m² brightness with auto-dimming (ambient light sensor).

Display tech: For very cold starts, consider low-temperature LCD formulations or OLED with derating plan.

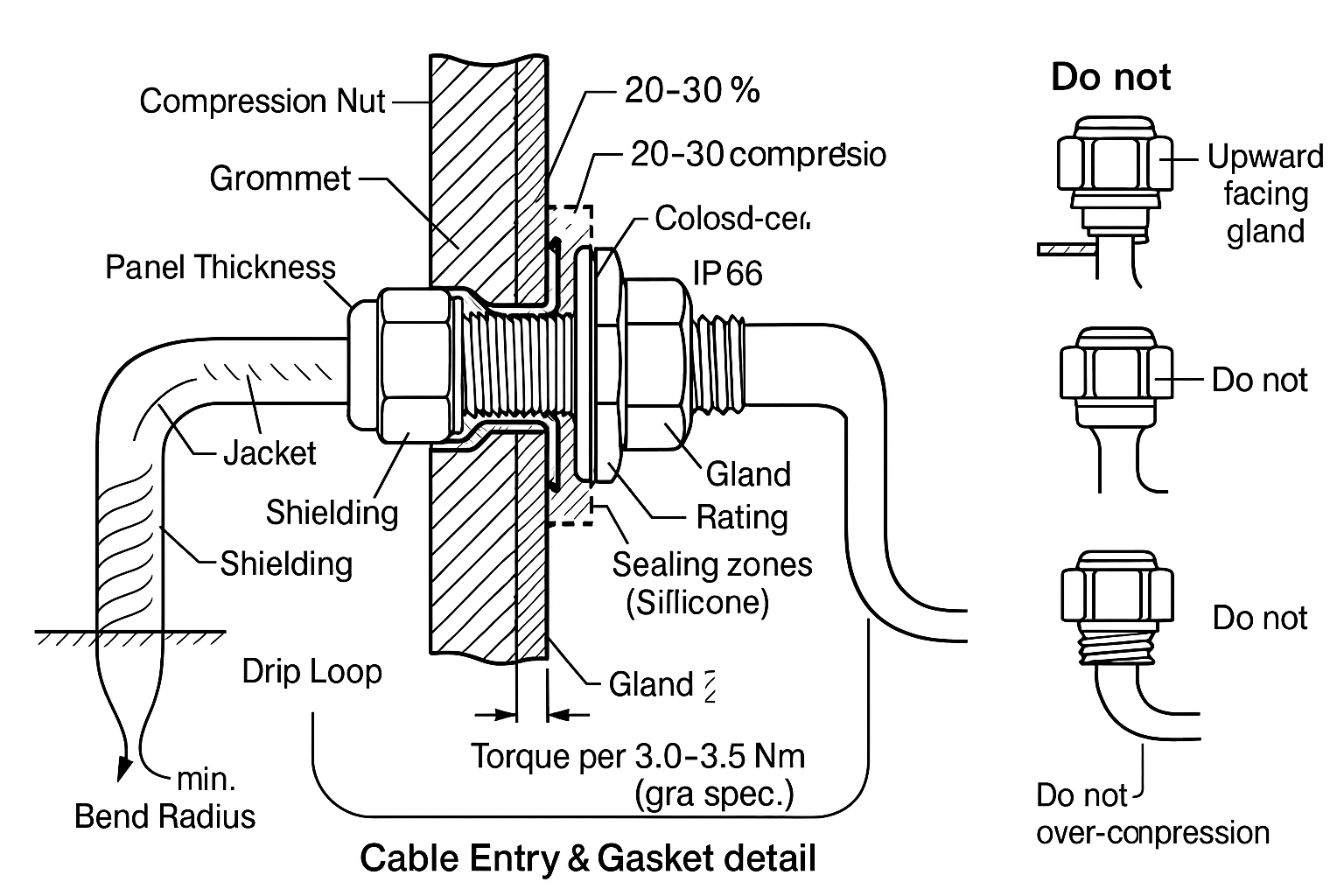

3) Installation best practices

Shading & orientation: Add sun-hood; avoid direct, normal incidence sunlight on the screen.

Enclosure: Use a vented rain-splash design with drip-edge and insect mesh; keep air path but block jets.

Sealing: Grommets and silicone O-rings on cable entries; pot unused knockouts; torque to spec.

Cable management: Drip loops on all cables; avoid upward-facing connectors.

Site placement: Face away from prevailing rain; elevate from standing water.

4) Routine inspection & care

4.1 Frequencies

Normal seasons: Monthly external inspection.

Rainy/high-humidity seasons: Weekly quick checks.

4.2 Cleaning

Method: Anti-static screen cleaner + lint-free wipes; light pressure only.

Do not use: Alcohol/solvent or abrasive cleaners (cause haze and coating damage).

4.3 Moisture control

Replace/refresh desiccant packs; inspect and replace seals/gaskets if hardened or cracked.

4.4 Power quality

Verify supply is within tolerance; add surge suppression/UPS or AVR where brownouts/spikes occur.

5) Seasonal operation tips

High heat: Improve ventilation or add a low-noise exhaust fan; avoid sustained 100% brightness in direct sun.

Low temperature: Pre-warm: power idle a few minutes before full load; specify low-temp LCD for sub-zero sites.

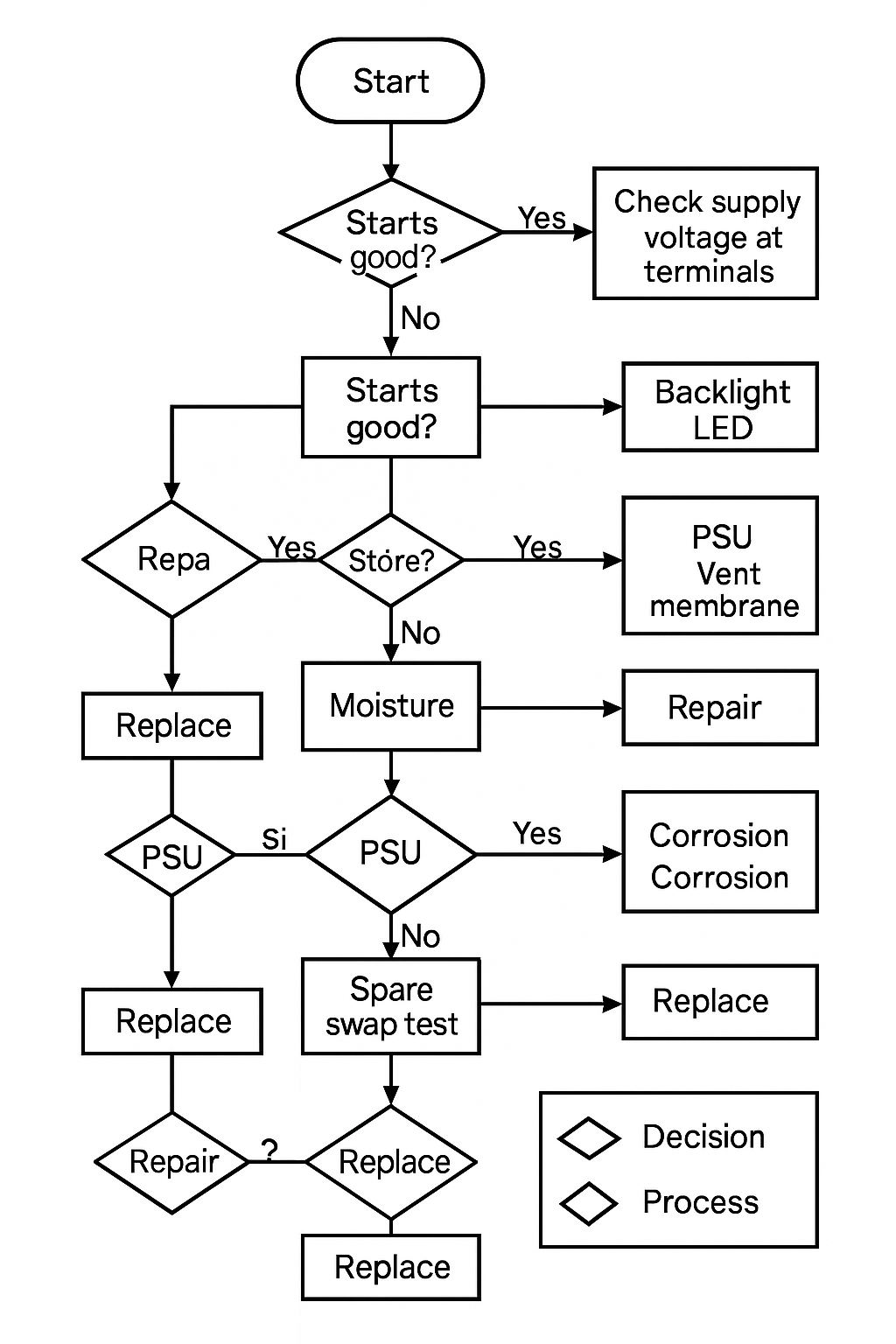

6) Field troubleshooting (safe, fast, traceable)

Make safe & power down.

Visuals: Look for water marks, haze, cracked window, UV-yellowed gasket.

Connectors: Reseat power/signal; check for corrosion or loose screws.

Substitution test: If possible, swap in spare screen or driver board to isolate cause.

Record & report: Log symptom, time, weather, and actions for reliability tracking.

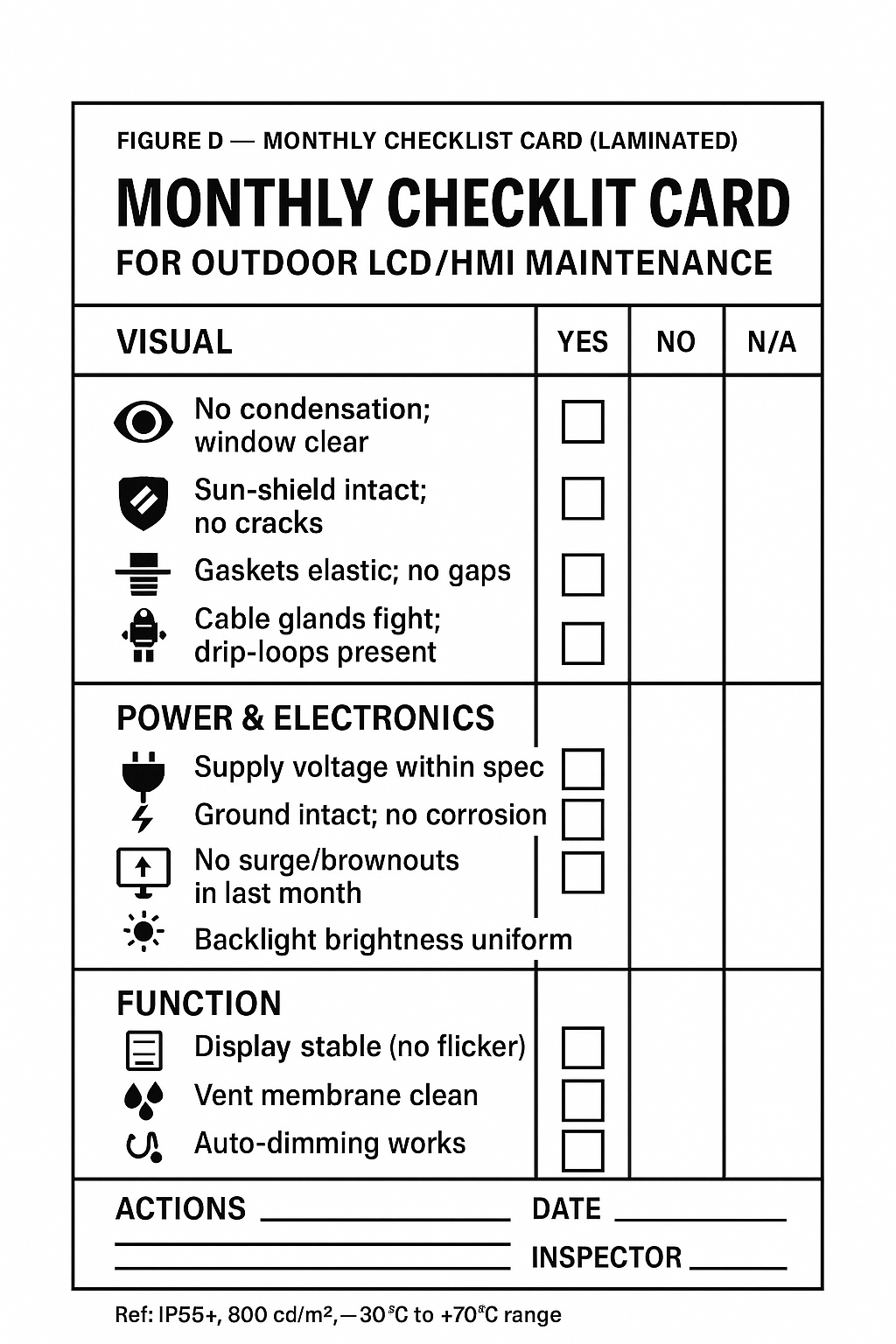

7) One-page maintenance checklist (printable)

A. Visual (front & enclosure)

□ No condensation/fog; window clear

□ Sun-hood intact; no cracks

□ Gaskets elastic; no gaps

□ Cable glands tight; drip-loops present

B. Power & electronics

□ Supply voltage within spec at terminals

□ Ground/bond intact; no corrosion

□ No surge/brownout events in last month (review log/UPS)

□ Backlight brightness uniform across screen

C. Function

□ Display stable (no flicker/ghosting)

□ Touch/keys respond across full area

□ Auto-dimming works under shadow/light change

□ On-screen colors neutral (no tinting/banding)

D. Moisture control

□ Desiccant replaced/dated

□ Vent membrane clean; enclosure pressure equalizes on door close

E. Actions taken

Notes / parts replaced / next review date

8) SOP — Cleaning & resealing (5–10 min)

Isolate power; hang LOTO tag.

Wipe display with approved cleaner; dry with lint-free wipe.

Inspect bezel and gasket; if tacky/cracked → replace.

Check gland compression; re-torque to rating; apply silicone where specified.

Replace desiccant; date the pack.

Power up; verify brightness and touch; log results.