Introduction

High-temperature steam and dense chemical liquids are at the core of coatings, adhesives, high-performance lubricants, and specialty fluids. For chemical plants, processing these high-viscosity materials means mastering intense heat and shear forces to ensure stable quality and consistent production.

This article explores cutting-edge process technologies to overcome common issues such as pipeline clogging and flow inefficiencies in high-viscosity systems.

1. From Advanced Powder Treatment to High-Energy Masterbatch

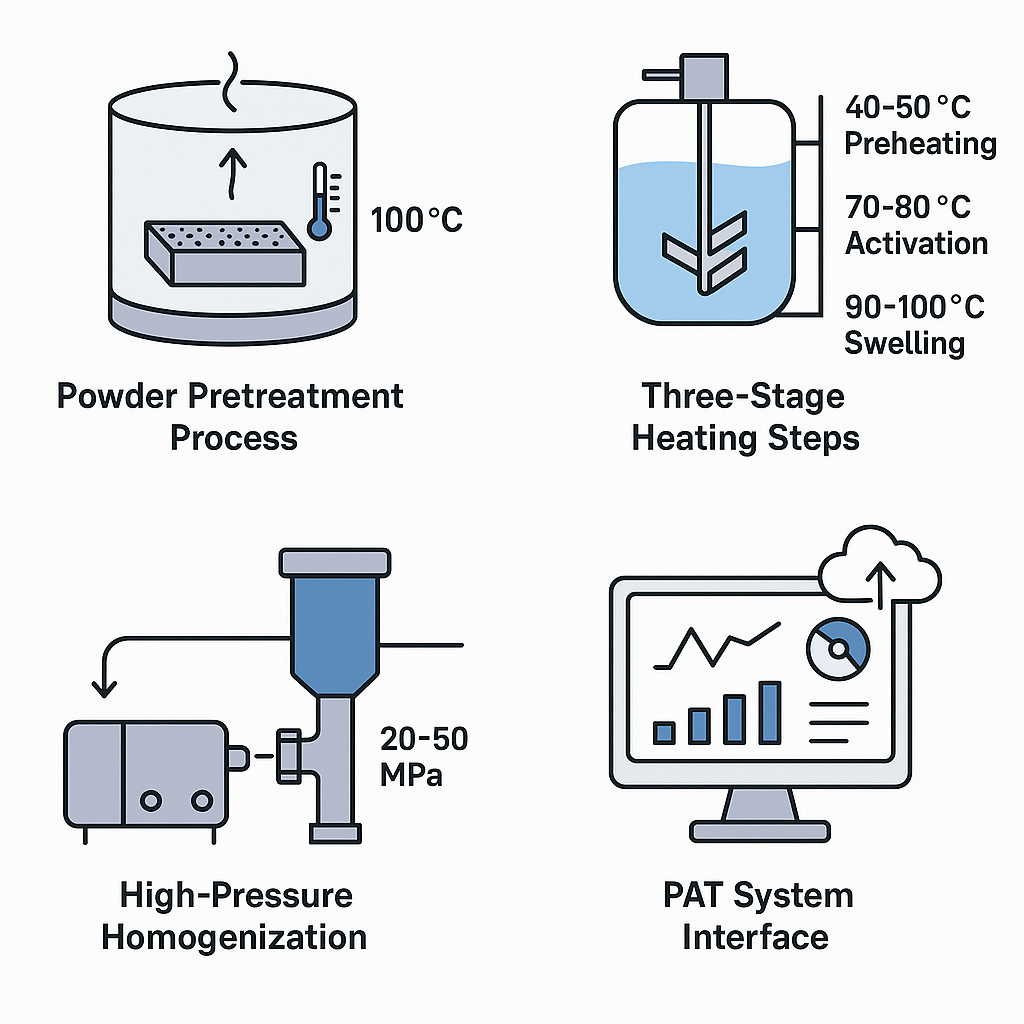

Powder Pretreatment

Moisture-sensitive powders like nano-silica and carbon black are preconditioned in ovens at approximately 100°C for 2-3 hours to reduce moisture below 0.1%. Without this step, powders may agglomerate upon feeding, disrupting subsequent processes.

Masterbatch Preheating

Stage 1: Preheat to 40–50°C to allow partial solvent evaporation.

Stage 2: Heat to 70–80°C for molecular activation and improved solubility.

Stage 3: Pre-swell at 90–100°C to significantly lower viscosity, facilitating dispersion.

Precision Metering

Dual systems combining weigh scales and flow meters with auto zero calibration keep formulation errors within ±0.1%, ensuring every batch maintains the ideal ratio.

This multi-step preparation ensures consistent and reliable raw material handling for downstream processes.

2. Multi-Stage Shearing for Nano-Scale Dispersion

Three-Level Dispersion

Coarse Dispersion: Propeller and pitched-blade impellers break down large aggregates.

Intermediate Dispersion: High-shear perforated plates achieve shear rates above 10⁴ s⁻¹.

Fine Dispersion: Ultra-high-pressure homogenizers (20–50 MPa) reduce particle sizes to 200–500 nm.

Intelligent Online Monitoring

Laser particle size analyzers and rheology sensors provide real-time feedback. If particle size or viscosity deviates, the system automatically adjusts parameters such as rotation speed, temperature, and pressure.

This intelligent dispersion strategy ensures uniformity and prevents clogging in high-viscosity pipelines.

3. End-to-End Thermal Management

Jacketed Piping with Heat Transfer Oil

Pipelines are fitted with steam jackets or heat transfer oil circuits to maintain optimal temperatures year-round, achieving over 90% thermal efficiency.

Heat Recovery Systems

Excess heat from ultra-high-pressure homogenizers is recovered via heat exchangers to preheat incoming materials, improving energy efficiency by 10–15%.

Proper thermal management minimizes flow resistance and eliminates cold spots that cause material solidification.

4. Dual-Layer Quality Control

Online PAT (Process Analytical Technology)

PAT systems monitor critical parameters such as particle size, viscosity, and interfacial tension in real time. Data is transmitted to a cloud platform, allowing engineers to remotely fine-tune the process.

Offline Comprehensive Testing

Laser diffraction, dynamic light scattering, capillary rheometry, and interfacial tension measurements ensure final product quality.

Combining online and offline testing creates a closed-loop system for process optimization and quality assurance.

5. Adaptive Packaging Systems

Multi-Format Flexibility

Packaging lines accommodate 5 kg, 20 kg, and 200 kg formats, with changeovers completed in under 30 minutes to support small-batch, multi-product operations.

Precision Filling and Nitrogen Purging

Automated filling systems achieve ±0.5% accuracy. Nitrogen purging reduces residual oxygen to below 1%, protecting high-viscosity products against oxidation and aging.

Flexible packaging strategies support both efficiency and product longevity.

6. Safety and Sustainability

VOC Recovery

A three-stage recovery process (condensation, adsorption, and re-distillation) achieves up to 95% solvent recovery, converting hazardous emissions into reusable resources.

Gas Monitoring and Explosion Protection

Sensors for flammable gases and organic vapors are installed throughout the system. Combined with explosion-proof electrical components and isolation enclosures, they create a fail-safe operational environment.

Integrated safety and environmental systems support compliance with global industrial standards.

Conclusion

By integrating digital intelligence and advanced mechanical systems, high-viscosity material processing has evolved from an experience-driven operation into a precise, controllable, and optimizable engineering process. From raw material preparation and multi-stage dispersion to smart monitoring, adaptive packaging, and environmental safeguards, each step demonstrates a synergy of craftsmanship and technology.