Introduction

In operational management and control optimization, I have always emphasized the importance of cross-departmental collaboration and collective problem-solving. A plant that is running steadily already has effective methods in place; what is often missing is a mechanism to identify these methods, standardize them, and then automate them. Advanced tools are not the core contradiction, nor are they the primary means of resolution. Two priorities must come first:

The ability to solve problems effectively.

A mechanism for cross-functional collaboration.

Common Pitfalls in Operational Management

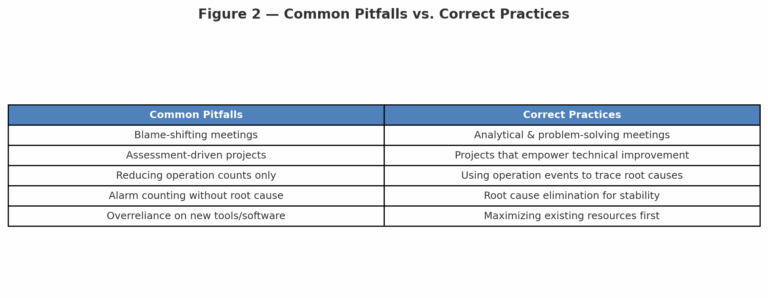

Ineffective Meetings

Many organizations struggle to hold meaningful cross-departmental meetings. These sessions often turn into platforms for blame-shifting and complaints, rather than opportunities for problem analysis and closed-loop execution.Misplaced Focus on Assessment

Operational management projects are sometimes reduced to assessment or compliance programs, rather than becoming initiatives that empower technical improvements.Narrow KPI Orientation

A common misinterpretation is to reduce operation frequency for its own sake, instead of using operational events as clues to trace root causes and improve automation.Confusion with Alarm Management

Operational management is frequently conflated with alarm management. Without identifying the root causes of process fluctuations, simply reducing numbers does little to enhance stability.Overreliance on Technology

Some plants equate operational management with advanced control systems or big data platforms. In reality, most operational challenges do not require advanced control. When projects focus only on new instruments, software, or platforms without fully utilizing existing resources, operational management risks becoming another form of “alarm counting.”

Key Success Factors

Problem-Solving Capability: Sustainable operational management depends first on the technical capacity to diagnose and resolve issues.

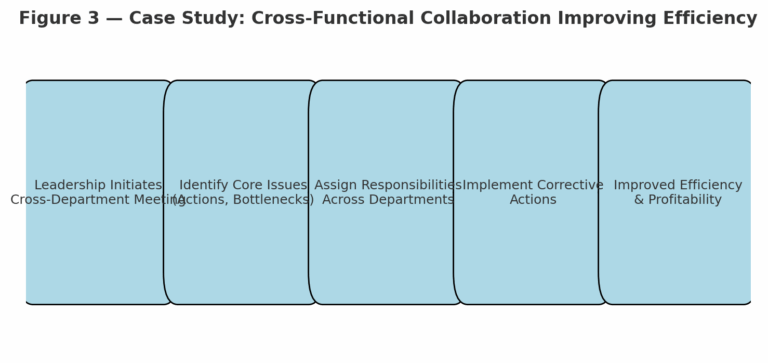

Cross-Functional Collaboration: A factory director or technical leader with the authority to organize across departments is crucial. One example is a new energy enterprise in Hubei, where leadership directly confronted problems, coordinated departments, and systematically improved both efficiency and profitability.

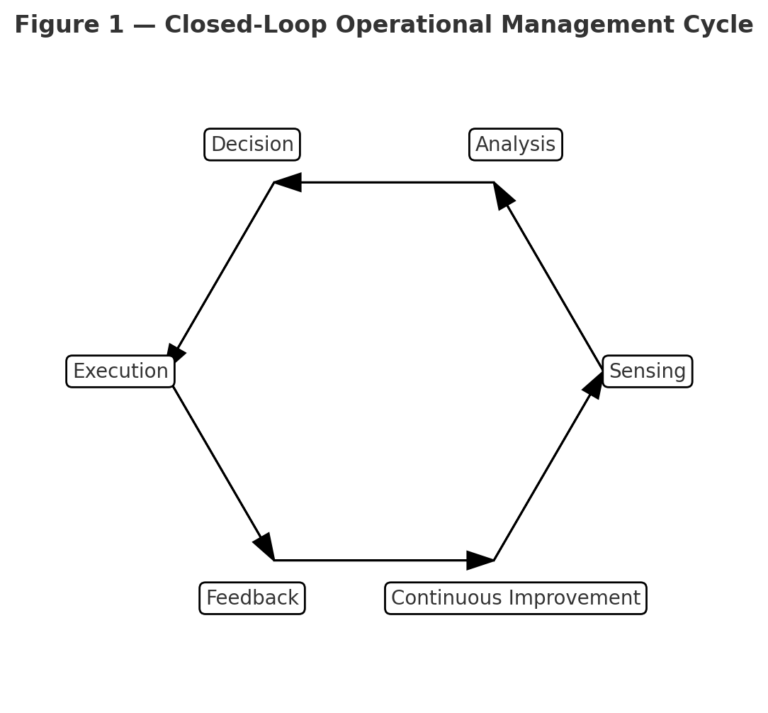

Closed-Loop Execution: Operational management must include sensing, decision-making, and execution. The most difficult—and most critical—parts are decision-making and execution.

Continuous Improvement: Operational management should not be treated as a one-time project but as a process of ongoing improvement, maximizing the potential of current systems before investing in new ones.

Distinguishing Operational Management from Advanced Control

Advanced Control: A tool within automation that can reduce interventions and alarms.

Operational Management: A broader discipline focused on stability, collaboration, and sustainable improvement.

The Relationship: Reduction in manual interventions is a result of good control optimization, not the starting point. Advanced tools are enablers, but not substitutes, for sound operational management practices.

Conclusion

Operational management is not about buying the latest software or deploying more sensors. It is about building the organizational ability to solve problems and the collaborative mechanisms to sustain improvement. With the right leadership and closed-loop processes, plants can transform operations from fragmented troubleshooting into a culture of systematic improvement.

“Advanced tools can support, but true excellence comes from capable people and effective collaboration.”