1. Control of Impurities and Salts Concentration

During the operation of the steam generator, soluble and insoluble impurities (such as calcium and magnesium ions) in the feedwater become increasingly concentrated as water evaporates. If blowdown is not performed regularly, the concentration of impurities in the boiler water will rise, which can reduce steam quality and potentially cause scaling on the heat transfer surfaces.

As steam has a limited capacity to dissolve salts, further accumulation of salts in the steam drum significantly increases the risk of scaling, impacts heat transfer efficiency, and may lead to overheating and failure of the pipe walls.

2. Removal of Sludge and Corrosion Products

After chemical treatment, hardness ions in the boiler water can form sludge, while metal equipment will generate corrosion products over time. If these solid substances settle at the bottom of the steam drum or on the heat transfer surfaces, they will reduce heat exchange efficiency and may cause under-scaling corrosion, posing a safety risk to the equipment.

Regular blowdown can effectively remove these deposits, keeping the boiler water clean and ensuring system stability.

3. Ensuring Steam Quality and Operational Safety

Even though a steam-water separation device is installed in the steam drum, trace impurities may still be carried by the steam during long-term operation. Proper blowdown reduces the concentration of dissolved solids in the boiler water and decreases the amount of salts carried by the steam, thus ensuring the purity of the steam and preventing contamination or corrosion of downstream equipment such as turbines.

Additionally, blowdown serves as an important means for monitoring and adjusting boiler water quality, effectively preventing abnormal phenomena such as foaming or water carryover.

4. Improving Thermal Efficiency and Extending Equipment Lifespan

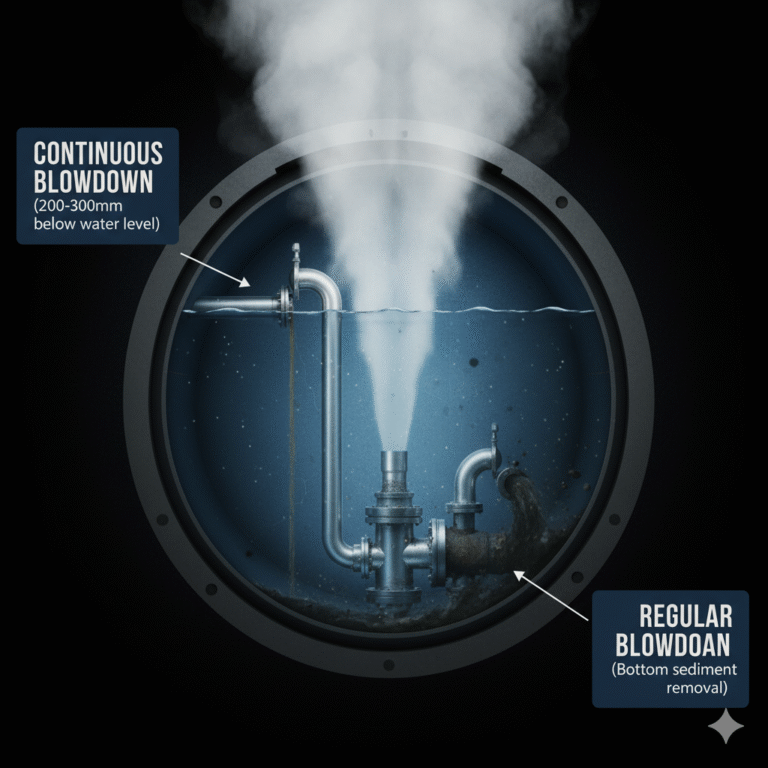

Scaling on the boiler’s heat transfer surfaces significantly increases thermal resistance, leading to higher fuel consumption and a greater risk of metal overheating. By properly implementing continuous blowdown (removing high-salinity boiler water from the upper part of the drum) and regular blowdown (removing sediment from the bottom), the heat transfer surfaces can remain clean, improving heat exchange efficiency and reducing the performance degradation of equipment due to scaling and corrosion, ultimately extending the lifespan of the equipment.

5. Blowdown Operating Standards

Continuous Blowdown: Perform blowdown at 200-300mm below the steam drum water level to remove high-salinity boiler water. The amount of blowdown should be dynamically adjusted based on water quality analysis results to maintain an appropriate concentration factor.

Regular Blowdown: Conduct short-term blowdown every 8-24 hours, focusing on removing sediment at the bottom of the steam drum. A blowdown rate of at least 1% is recommended.

Safety Requirements: Before blowdown, confirm that the equipment’s temperature and pressure are within safe ranges to prevent operational risks due to high temperature or pressure.

6. Conclusion

Blowdown is an essential step in maintaining the efficient, stable, and safe operation of the steam system. By scientifically controlling the frequency and amount of blowdown, along with dynamic adjustments based on water quality monitoring and operational parameters, the boiler system’s water quality can be balanced, thermal efficiency optimized, and equipment lifespan prolonged.