1. Don’t Be Fooled by “Surface Calmness”

One of the biggest misconceptions in workshop safety is the familiar saying, “If no hazards are found, then everything is safe.” Just because the equipment is running smoothly and the floor looks clean doesn’t mean everything is in order. Many accidents occur in environments that initially appear to be problem-free.

Safety is not a choice, but a matter of survival. Once an incident occurs, production halts, financial losses mount, and reputation collapses. In the worst cases, lives are at risk. The real danger lies in the hazards you don’t see.

Hazards are like leftovers in a refrigerator – they may appear fine on the outside, but inside, they have already gone bad. A loose screw or a damaged insulation layer can become the trigger for the next accident.

2. The First Line of Defense is Not the System, But the People

Data shows that 80% of safety incidents occur at the team level. The team leader is the first person to spot potential hazards. Being on the front lines every day, they are key in identifying hidden risks. If they lack a keen eye, invisible dangers can silently build up in the corners.

The key to a safety system is not simply “having one,” but in ensuring it is implemented with every action. Rather than regret later, it’s better to proactively check for hazards now.

3. Five High-Risk Areas for Workshop Hazards

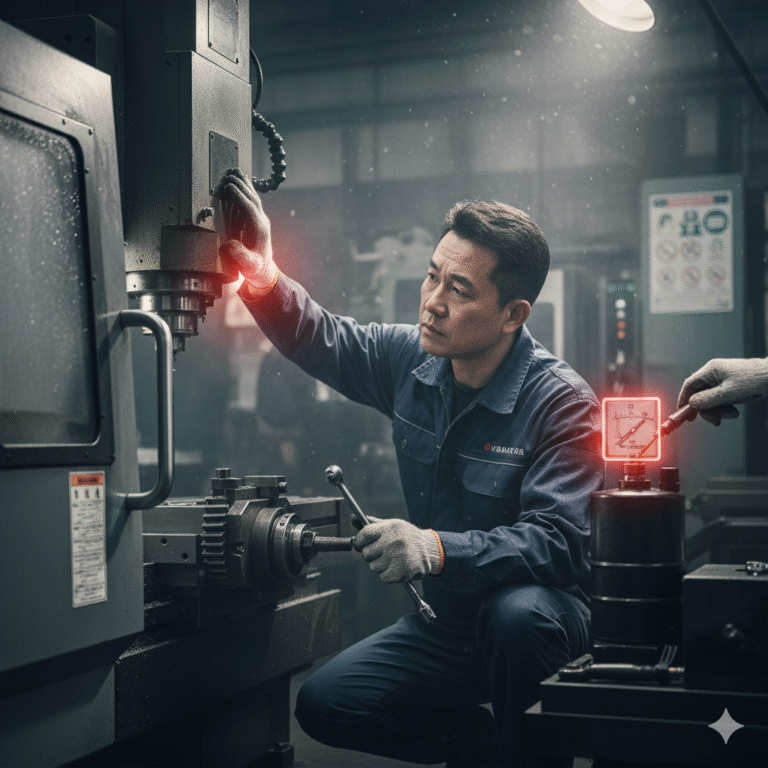

1) Equipment Area: Listen to Sounds, Check Bolts, Feel Temperature

Strange noises are not background noise. Spend 30 seconds each morning to listen to your equipment. If the noise becomes dull or sharp, it’s a warning. Small noises, if left unchecked, can lead to broken shafts or even injuries.

Loose bolts are a big hazard. Every week, use a wrench to check each bolt. If it’s loose, tighten it. A “half-turn loose” on a high-speed gear can be the cause of a serious injury.

Don’t skimp on lubricating oil. If the oil level is below the required mark, friction increases and the machine may stop unexpectedly. Follow the instructions to add oil—every drop counts in preventing accidents.

2) Passageways: Clear Paths Save Lives

Material beyond the line = blocked escape routes. Passageways must be at least 1.2 meters wide. Any obstruction should be cleared immediately. In case of fire, a narrow pathway can make escape impossible.

Oil stains and metal shavings are hidden traps. Clean up oil stains and metal shavings thoroughly at the end of each shift. “I’ll clean it later” could turn into “lying down to recover from an injury.”

Broken lights = blind spots. Check the lights weekly. If any are broken, replace them within 24 hours. Proper lighting is essential to maintaining a safe environment.

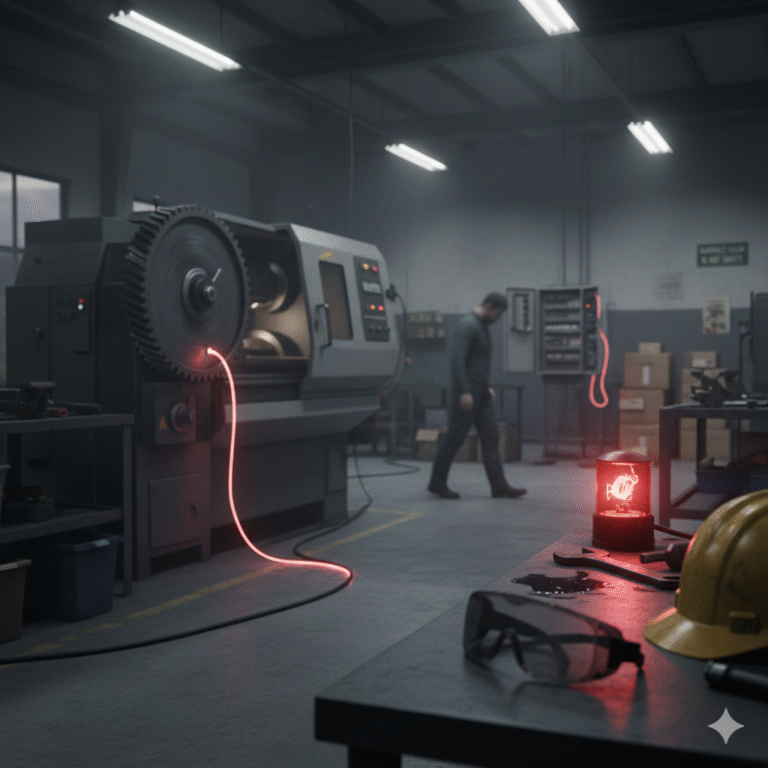

3) Electrical Area: Wires Don’t Complain, But They Can Be Deadly

Exposed wires = electrical hazards. Damaged wires, whether from a forklift or being pulled by a corner, pose the greatest danger. If you spot a damaged wire, replace it immediately. Temporary fixes like tape are not enough.

Overloaded outlets = fire hazard. Each power strip should only be used for three devices. High-power equipment should have its own circuit.

Cluttered distribution boxes = blocked power cut-off channels. Keep a 1-meter radius clear around distribution boxes. Close the doors securely and clean the dust monthly.

4) Fire Safety Area: Fire Extinguishers Aren’t Decorations

Pressure gauge in the red zone = a dud. Check the pressure, spray nozzle, and inspection date each month. If expired, replace immediately.

Fire hydrants blocked by 1/3 = no water in an emergency. Unclog fire hoses monthly, remove rust, and ensure a 1.2-meter space is available around them.

Emergency lights not working = escape risk. Test the emergency lights every month. If they don’t work, replace the batteries right away.

5) Work Behavior Area

Protective gear is not optional. Helmets, goggles, and gloves aren’t just for show—they are lifesaving equipment. If your goggles fog up, use soap and water to clear them.

Fatigue can lead to mistakes. After working for 3 continuous hours, the error rate increases drastically. Take a 10-minute break every 2 hours. Machines can stop; your body can’t afford to break down.

Rushing leads to skipping safety steps. Skipping pre-operation checks or leaving sleeves unbuttoned can result in accidents. Spending 30 more seconds can save you a lifetime of regret.

4. Make Hazard Inspections Part of Your Daily Routine

Safety isn’t just a slogan—it’s a habit. Ask yourself three questions every day:

Am I operating safely?

Are there any abnormalities around me?

Are the emergency devices functional?

If you spot a hazard, correct it immediately. Don’t put it off until tomorrow. Make safety a closed-loop process—whoever finds the hazard, fixes it, and checks it again.

Leadership should actively inspect, and employees should share “safety stories” to make safety more than just words on paper.

5. Conclusion

“Not finding hazards” does not equate to safety. Proactively inspecting is true safety. Start today by checking:

Listen for unusual sounds in your equipment.

Check that your passageways are clear.

Feel if the electrical wires are warm.

Let’s eliminate hazards and ensure a “safe day at work.”