Abstract

In radar level measurement, users are often confused between normal-temperature and high-temperature radar level transmitters. The key difference lies in temperature resistance and structural design. This article explains their distinctions, common working principles, and typical application scenarios, providing a quick selection guide for engineers.

1. Core Differences

1.1 Temperature Resistance

Normal-Temperature Radar Level Transmitter:

Designed for applications within –40°C to +150°C. Exceeding this range can lead to circuit failure or probe damage.High-Temperature Radar Level Transmitter:

Specifically engineered for 200°C and above, with some models capable of withstanding 500°C+. They remain stable under direct exposure to hot media or radiant heat.

1.2 Structure and Materials

Normal-Temperature Models:

Probes typically made of standard stainless steel (e.g., SS304). Housings and electronics lack high-temperature protection.High-Temperature Models:

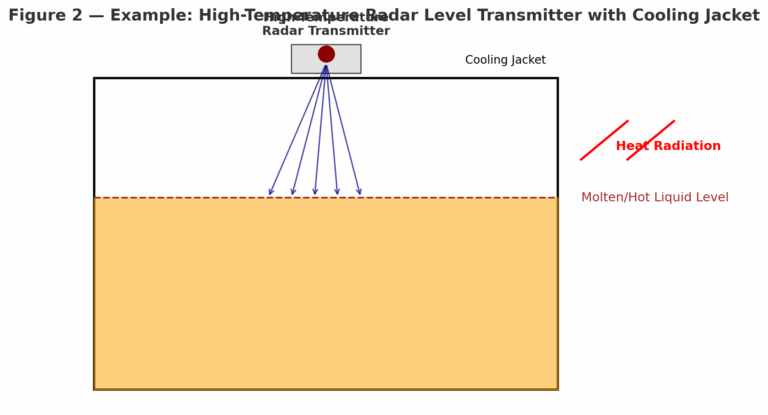

Probes made of SS316L, ceramics, or other heat-resistant materials. Housings include insulation layers, and electronics are equipped with heat sinks or cooling jackets to block thermal conduction.

1.3 Protective Design

Normal-Temperature Models: Simple design, without special thermal shielding.

High-Temperature Models: Additional sealing, dust protection, and thermal radiation shielding ensure reliable operation in harsh environments.

📊 Recommended Table 1 — Comparison of Normal vs. High-Temperature Radar Level Transmitters

| Feature | Normal-Temperature Model | High-Temperature Model |

|---|---|---|

| Operating Range | –40°C to +150°C | 200°C to 500°C+ |

| Probe Materials | SS304 | SS316L, ceramics, high-temp alloys |

| Housing Design | Standard | Insulated, cooling jacket, heat sink |

| Protection | Standard sealing | Enhanced sealing, thermal shielding |

| Typical Use | Water tanks, oil storage, food processing | Steel ladles, reactors, boilers |

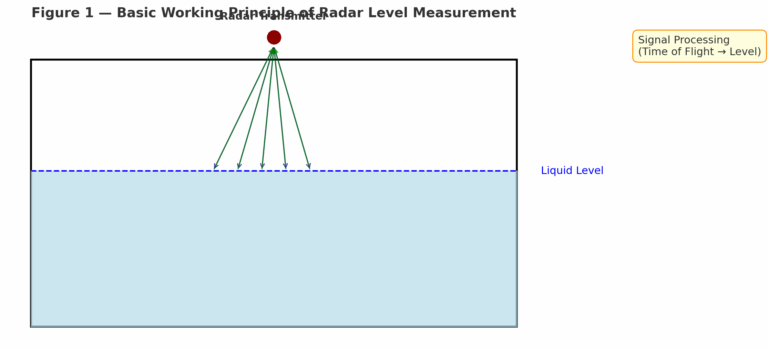

2. Common Principle

Both types operate on the same radar principle:

Transmitting high-frequency radar waves (26 GHz / 80 GHz).

Waves reflect from the liquid surface.

The receiver calculates the time of flight to determine the exact level.

They are independent of medium density, viscosity, and dust conditions, making them versatile across industries.

3. Application Scenarios

3.1 High-Temperature Radar Level Transmitters

Used in extreme environments such as:

Metallurgy: Steel ladles, slag pits, molten iron containers.

Chemical Industry: Resin reactors, organic synthesis tanks, molten salt storage.

Energy/Power: Steam boilers, thermal oil storage, biomass melting furnaces.

📷 Figure 2 — Example: High-Temperature Radar Level Transmitter with Cooling Jacket

3.2 Normal-Temperature Radar Level Transmitters

Best suited for standard or mild-temperature conditions:

Municipal Water: Clean water tanks, wastewater sedimentation basins.

Petrochemical: Crude oil tanks, finished product tanks.

Food & Beverage: Juice storage tanks, fermentation tanks.

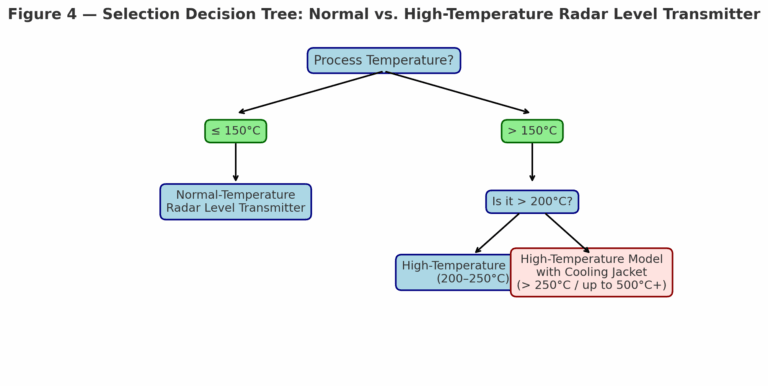

4. Summary and Selection Guide

For conditions below 150°C, a normal-temperature radar level transmitter is sufficient.

For high-temperature liquids, steam, or reactor vessels, a high-temperature model is mandatory.

⚠️ Note: Incorrect selection may cause probe burnout, signal loss, or measurement failure, leading to downtime and costly maintenance.

✅ Selection Tip: Always match the radar transmitter’s thermal design with the actual process temperature, and consult manufacturers for specific probe designs and cooling accessories when temperatures exceed 200°C.