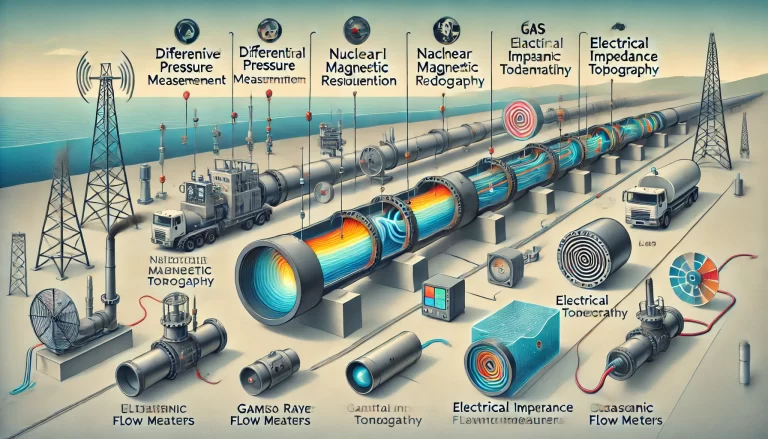

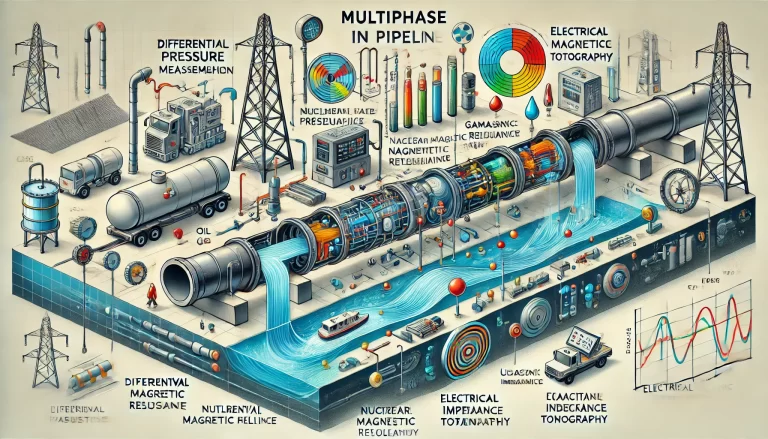

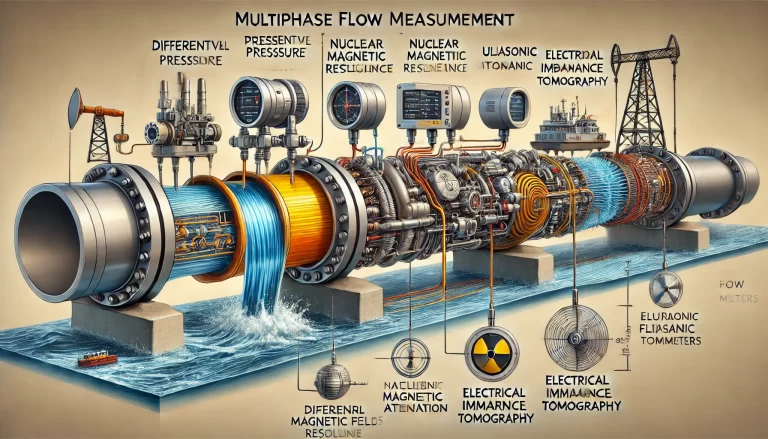

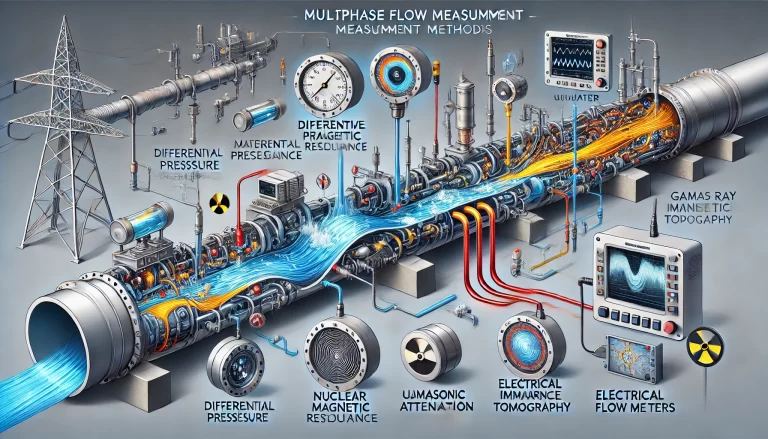

Multiphase flow measurement is a critical technology used in industries where fluids consisting of different phases (such as gas, liquid, and solid) are transported together through pipelines. This is particularly important in the oil and gas industry, where water, oil, and gas often co-exist in extraction and production processes. Accurately measuring the flow rates of each phase is essential for optimizing production, improving safety, and ensuring the efficient operation of systems. Unlike single-phase flow, where measuring flow is relatively straightforward, multiphase flow involves complexities due to the different properties and behaviors of each phase in a mixture.

Here is a detailed look at some of the most common methods for measuring multiphase flow:

1. Differential Pressure (DP) Method

The Differential Pressure (DP) method is based on measuring the pressure difference across a constriction in the pipeline, such as an orifice plate, venturi tube, or nozzle. The flow through the constriction causes a pressure drop, and by applying the Bernoulli equation, the flow rate can be estimated. While this method works well for single-phase fluids, it presents challenges in multiphase flow because the pressure drop is influenced by the presence of different phases with varying densities and flow regimes.

To use this method for multiphase flow, correction factors or empirical models are often employed to account for the effects of gas, liquid, and sometimes solid phases. This approach requires careful calibration and a good understanding of the flow characteristics for each specific application.

2. Nuclear Magnetic Resonance (NMR)

Nuclear Magnetic Resonance (NMR) measures the magnetic properties of the atomic nuclei in the fluid. Different phases (such as oil, water, and gas) interact with magnetic fields differently. By analyzing these interactions, NMR can provide information on the phase composition and flow rates. This method is particularly advantageous because it is non-invasive and does not require contact with the fluid.

However, NMR technology is expensive and typically used in high-end applications or research settings. It is also sensitive to the operating environment, meaning it is not always practical for all field applications, particularly in harsh or remote environments.

3. Gamma Ray Attenuation

Gamma ray attenuation is another non-invasive technique where a beam of gamma rays is passed through the flow. The attenuation, or weakening, of the gamma rays depends on the density of the material they pass through. By measuring the attenuation, the relative proportions of gas, liquid, and solid phases can be estimated.

This method is commonly used in gas-liquid or oil-water-gas systems where the difference in densities between phases is significant. Gamma ray devices are relatively compact and can be used in environments where space is limited. However, safety concerns around the use of radioactive sources, along with the method’s limited accuracy in systems with finely dispersed phases, make it less widely applicable in some scenarios.

4. Electrical Impedance Tomography (EIT)

Electrical Impedance Tomography (EIT) is based on the principle that different phases of fluid have different electrical conductivities. For instance, water has a higher conductivity than oil or gas. EIT works by placing electrodes around the perimeter of the pipeline and applying a small current. The resulting voltage patterns are used to create a tomographic image of the fluid’s conductivity distribution, which provides insight into the phase distribution and flow characteristics.

EIT is non-invasive and can be used to measure flows in real-time. It is most effective in gas-liquid flows or systems with significant conductivity differences between phases. However, it struggles in cases where the phases have similar conductivities, such as in some oil-water mixtures.

5. Ultrasonic Flow Meters

Ultrasonic flow meters use high-frequency sound waves to measure the velocity of the flow. There are two common types of ultrasonic flow measurement: transit-time and Doppler. In the transit-time method, sound waves are sent through the fluid, and the time it takes for the waves to travel between sensors is measured. The difference in transit time between the upstream and downstream sensors can be used to calculate the flow velocity. Doppler ultrasonic meters, on the other hand, measure the frequency shift of sound waves reflected from particles or bubbles within the fluid to determine flow velocity.

Ultrasonic flow meters are non-intrusive and can provide real-time measurements. They are particularly useful for gas-liquid flows and are widely used in the oil and gas industry. However, they are less effective when the fluid contains a large amount of solid particles or if the phases are finely dispersed.

6. Capacitance and Conductance Measurement

Capacitance and conductance methods are based on the dielectric properties of the fluids. In capacitance measurement, electrodes are placed along the pipe, and the dielectric constant of the fluid is measured. Since each phase (oil, water, and gas) has a different dielectric constant, this allows the detection of the proportions of each phase. Conductance measurement works similarly, but it measures the electrical conductivity of the fluid instead of the dielectric constant.

These methods are relatively simple and inexpensive, and they work well in systems with clearly distinct phases like oil-water or water-gas mixtures. However, their accuracy is limited in more complex multiphase flows, such as those with finely dispersed emulsions or slurries.

7. Multiphase Flow Meters (MPFMs)

Multiphase flow meters (MPFMs) are specialized devices designed to measure the flow rates of different phases in a mixture simultaneously. These meters typically combine several techniques, such as differential pressure, gamma ray attenuation, and capacitance measurement, to provide accurate flow rates for each phase.

Modern MPFMs often incorporate advanced algorithms and data fusion techniques to improve accuracy. These meters are capable of handling a wide variety of flow conditions and are increasingly used in oil and gas production to measure the output from wells. While MPFMs provide high accuracy and real-time data, they are expensive and require regular calibration and maintenance to perform effectively in the field.

8. Optical Flow Measurement

Optical methods involve using lasers or high-speed cameras to visually monitor the flow. Laser Doppler anemometry (LDA) and particle image velocimetry (PIV) are two optical methods that can be used to measure the velocity of particles or droplets in the flow. These methods can provide highly detailed information about the flow structure and phase distribution, making them valuable tools for research and development.

However, optical methods require clear visibility of the fluid, which limits their application to transparent pipelines or laboratory settings. Additionally, these methods are sensitive to lighting conditions and particle sizes, making them less practical for industrial use in opaque pipelines or complex flow environments.

9. Radio Frequency (RF) Methods

Radio frequency (RF) methods involve sending electromagnetic waves through the fluid and measuring the changes in wave propagation. The dielectric properties of the fluid affect the speed and attenuation of the RF waves, allowing the measurement of the different phases in the flow. This method can provide accurate phase fraction data and is particularly effective in low-conductivity systems.

RF methods are non-invasive and can be used in both liquid and gas-liquid systems. However, their effectiveness diminishes in high-conductivity fluids, such as those with high water content, and their performance can be affected by temperature and pressure variations.

Conclusion

The measurement of multiphase flow is a complex and evolving field that requires a careful selection of methods based on the specific properties of the fluid and the operating environment. Technologies like differential pressure, gamma ray attenuation, and ultrasonic flow meters have been the backbone of industrial multiphase flow measurement for decades. Meanwhile, advanced methods like nuclear magnetic resonance and multiphase flow meters are providing more accurate and detailed insights, though at a higher cost.

In practice, no single method is universally superior; the best approach often involves combining multiple measurement techniques and applying sophisticated data processing algorithms to account for the complexities of multiphase flow.