Transmitters such as pressure, differential pressure, and level transmitters are vulnerable to moisture ingress in humid environments (e.g., outdoor installations, damp workshops, underground pits, wastewater treatment plants). Water vapor can penetrate the housing, terminal compartments, or sensor diaphragms, leading to short circuits, signal drift, distorted outputs, or even total failure.

To ensure reliable operation, a comprehensive moisture protection strategy must address selection, installation, sealing, and routine maintenance as follows:

1. Selection Stage: Choose Moisture-Resistant Transmitter Designs

Define Protection Level Requirements

Match the IP/NEMA rating to environmental humidity risks:General humid areas (e.g., indoor condensation zones): IP54 (dust-proof + splash-proof), NEMA 4.

Wet or spray-prone environments (e.g., washdown areas, outdoor rain): IP65 (dust-tight + low-pressure water jets), IP66 (high-pressure water protection), NEMA 4X (corrosion-resistant).

Submersed or high humidity + corrosive environments (e.g., sewage pits): IP67 (temporary immersion), IP68 (continuous immersion), or explosion-proof and fully sealed types.

Focus on Moisture-Resistant Core Components

Prefer welded diaphragms over adhesive types for capacitive transmitters.

Ensure circuit boards are potted with epoxy resin for moisture protection.

Look for Venting or Drainage Features

Models with breathable vents (e.g., PTFE vents) allow pressure equalization while blocking water ingress and minimizing condensation.

For flange-mounted transmitters, select designs with drainage holes (e.g., φ3–5 mm) to periodically release internal condensate.

2. Installation Stage: Minimize Moisture Exposure Risks

Optimize Mounting Location

Avoid low-lying areas, steam pipes, spray zones, and cooling tower outlets. If unavoidable, maintain a minimum 1.5 m clearance and use protective shielding.

Mounting Orientation

For outdoor installations, mount the transmitter body at a 15°–30° downward tilt with the terminal housing facing downwards or sideways to prevent water pooling.

Install weatherproof sun/rain shields (stainless steel or fiberglass) with drainage holes at the bottom.

Probe Interface Protection

Use dual-seal structures (e.g., metal bellows + O-ring) at probe insertion points to prevent water or process fluid backflow into the transmitter body.

For flanged connections, use water-resistant gasket materials (e.g., NBR, FKM) and tighten bolts evenly using a cross-pattern sequence.

3. Sealing and Electrical Connections: Strengthen Moisture Barriers

Terminal Housing Sealing

Ensure rubber or silicone gaskets are intact and free from aging or damage. Clean mating surfaces before closing and tighten cover screws evenly to prevent gaps. Replace hardened or cracked seals immediately.

Cable Entry Protection

Use waterproof cable glands sized to fit the cable diameter. Tighten until the internal rubber seal grips firmly without folds or gaps. Optionally apply silicone grease on the inner seal for enhanced protection.

Enhanced Sealing for Cable Joints

Apply sealant at critical junctions:

Front: gland-to-instrument connection.

Middle: gland thread lock.

Rear: gland-to-cable compression point.

Wrap high-pressure self-fusing tape over the sealed areas, followed by PVC protective tape for complete coverage.

Internal Moisture Control

For non-explosion-proof models in highly humid areas (>90% RH), place desiccant packs inside the terminal compartment and replace regularly. Optionally spray conformal coating (acrylic/silicone-based) on circuit boards for added protection.

4. Routine Maintenance: Inspect and Restore Moisture Protection

Periodic Cleaning and Drying

Conduct weekly or monthly inspections based on humidity levels. Blow dry the transmitter exterior and terminal compartment with dry compressed air. Wipe off condensation and air out the terminal housing (ensure power is off).

Seal and Gland Inspection

Quarterly check for gasket/gland seal aging or cracking. Retighten flange bolts per torque specs to counter vibration-induced loosening.

Special Measures for Extreme Environments

Submersible Transmitters: Reapply underwater epoxy sealant after each maintenance. Annually test housing integrity with pressure tests.

Corrosive Humid Environments: Apply PTFE coatings on sensor diaphragms, apply petroleum jelly on terminals, and shorten maintenance cycles to 1–2 months.

5. Emergency Repairs: Handling Moisture Damage

If moisture ingress causes signal drift, short circuits, or no output:

Immediately power off the device.

Remove the circuit board and wipe with anhydrous alcohol to remove moisture and salts. Dry gently with a hot air gun at ≤60°C.

Purge diaphragms with dry nitrogen or air; avoid physical contact with sensitive surfaces.

Reassemble, apply low-voltage test (e.g., 12V for a 24V transmitter), recalibrate, and resume normal operation.

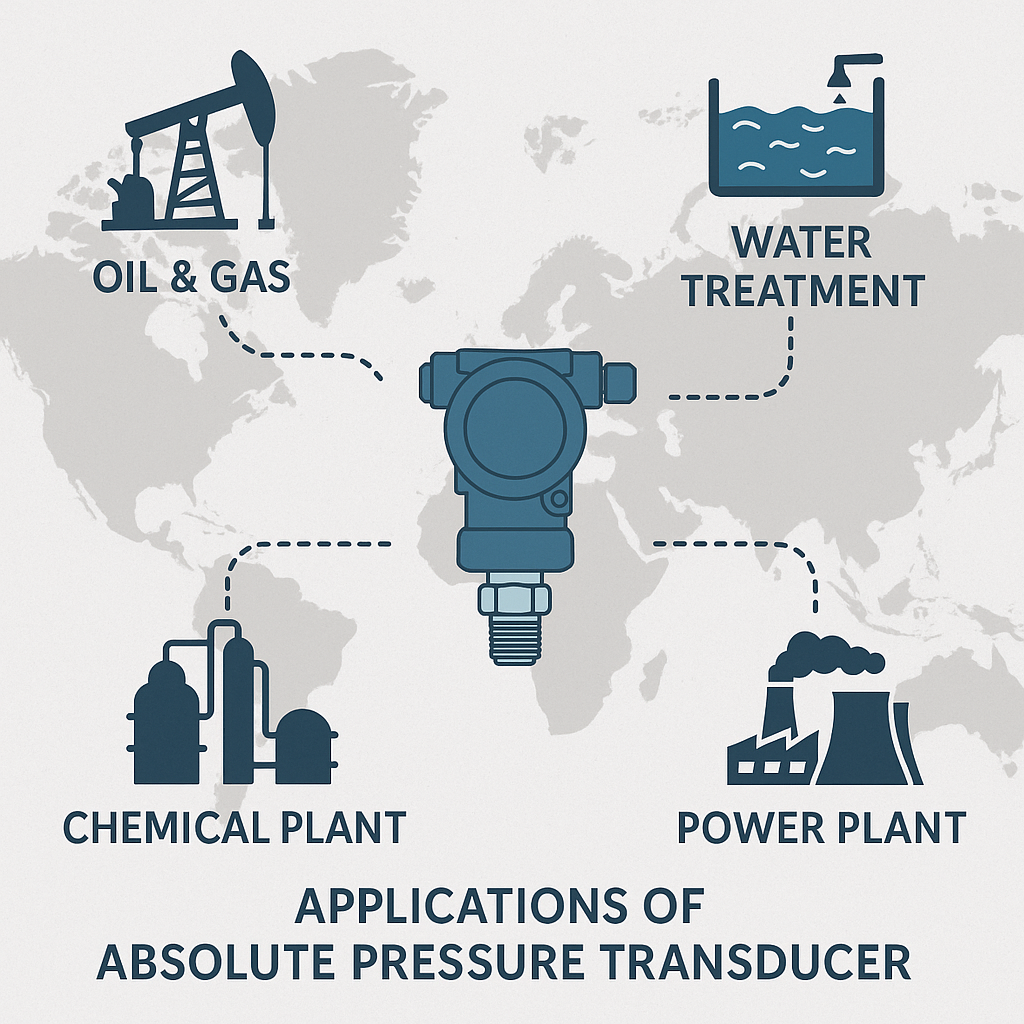

By implementing “fit-for-purpose selection + installation avoidance + reinforced sealing + routine maintenance”, the reliability of transmitters in high humidity environments can be significantly improved. Industries such as chemical processing, water treatment, and food manufacturing should incorporate these moisture protection measures into their standard operating procedures (SOP) to prevent measurement failures, production disruptions, and quality issues.