Migration of level transmitters refers to the adjustment process when there is a deviation between the measured liquid level and the actual liquid level due to factors such as installation position, medium properties, or isolation liquids. To enable the transmitter to correctly indicate the liquid level, a migration process must be applied, which includes no migration, negative migration, and positive migration.

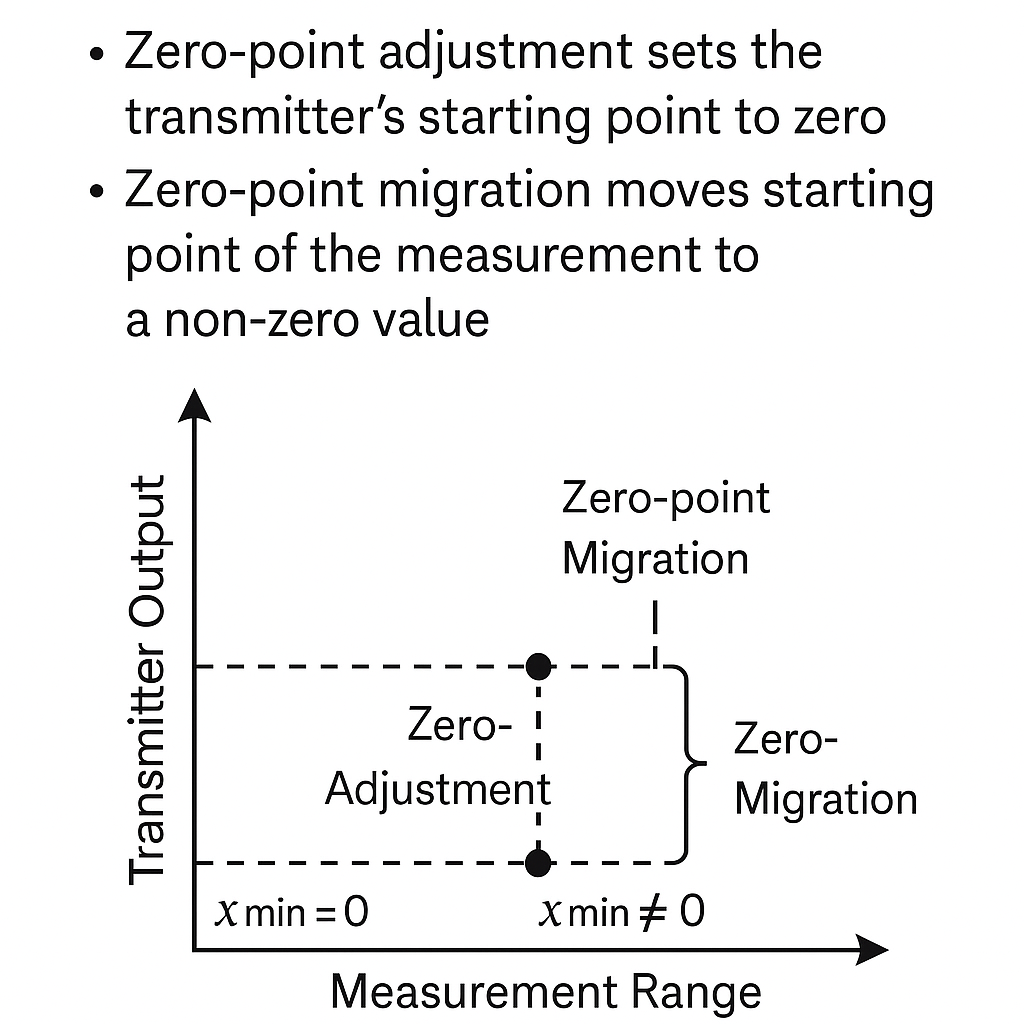

Migration refers to shifting the measurement range of the transmitter without changing the span. It’s important to note that the zero-point adjustment and zero-point migration are distinct. Zero-point adjustment occurs when the transmitter’s input signal (△p) is zero, but the output does not read zero. Zero-point migration, on the other hand, involves adjusting the output to zero when the input signal (△p) is not zero.

As illustrated below:

Zero-point adjustment sets the transmitter’s starting point to zero.

Zero-point migration moves the starting point of the measurement to a non-zero value:

Negative migration: Moves the start point below the reference point (zero).

Positive migration: Moves the start point above the reference point (zero).

Migration is represented either by how much input signal can be shifted or as a percentage of the measurement range.

2. When is Migration Necessary?

Migration is widely used in various industrial scenarios, including but not limited to:

Double-flange level transmitters: Suitable for measuring the liquid level in sealed containers. They can measure high-viscosity, crystallizing, precipitating, and corrosive media. When installed on-site, due to the height difference between the upper and lower flanges, migration is necessary.

Single-flange level transmitters with capillary tubes: Suitable for open container level measurements. When measuring the level in a sealed container, if the installation point is higher or lower than the lowest level tap, migration is required.

Differential pressure transmitters with isolating tanks: In the case of highly corrosive or viscous liquids, an isolating liquid tank is required to transfer the pressure signal. The effects of the liquid column in both the medium and the isolating liquid must be considered, and migration is necessary to ensure accurate readings.

Personal Experience Tip: In actual practice, for measuring levels with double-flange transmitters, it’s common to set the lower limit of the range by using the PV value when the isolation valve is closed, and the flanges are exposed to air. Then, add the calculated range to set the upper limit.