1. Introduction

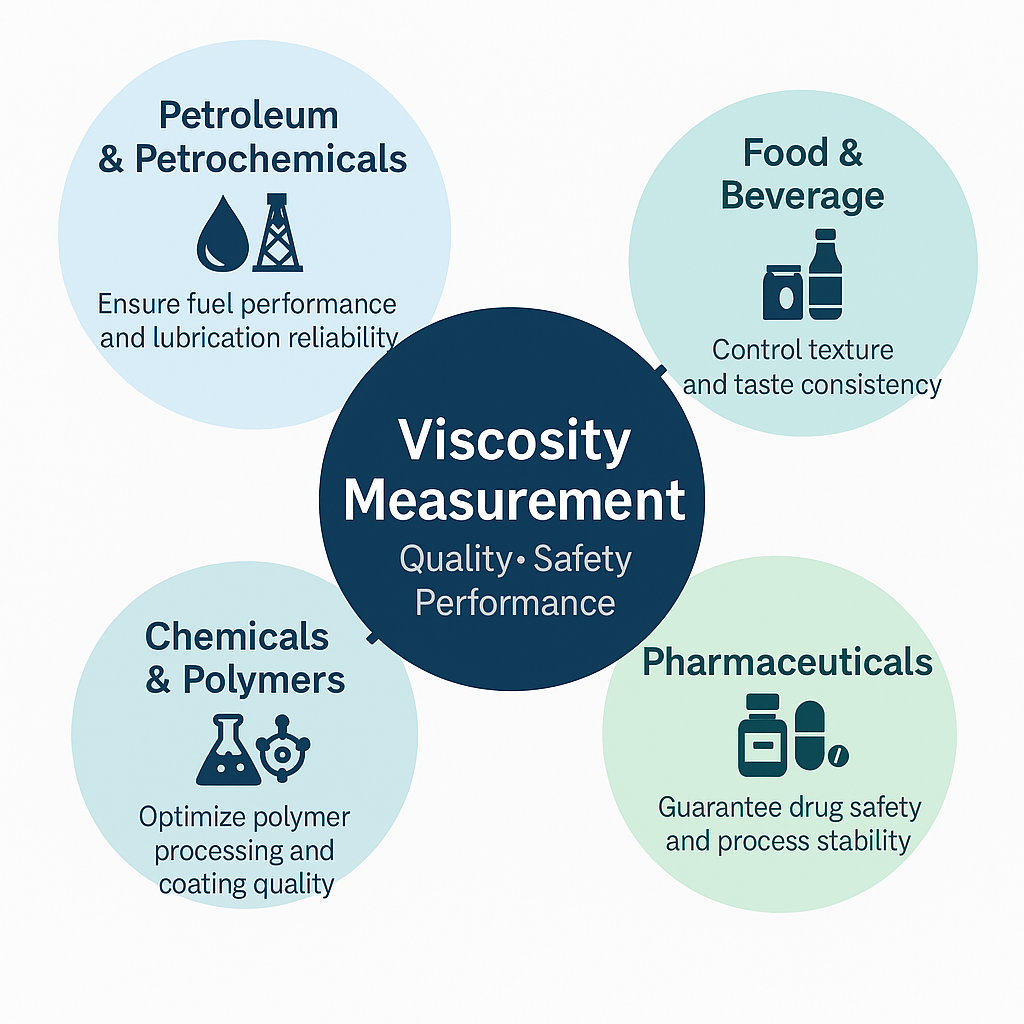

In industries such as petroleum, chemical, food, and pharmaceuticals, viscosity is a critical parameter for evaluating product performance and controlling production processes. The viscometer, as the core measurement tool, directly determines the stability of product quality and the reliability of research data.

Therefore, regular calibration and verification of viscometers form the cornerstone of enterprise quality control and standardized management.

2. Why Calibration Is Essential

Viscometers (e.g., rotational, capillary types) inevitably experience mechanical wear, electronic component aging, temperature fluctuations, or operator-induced deviations over time.

An uncalibrated instrument may provide readings that appear “stable” but are not “accurate.” Such hidden errors can result in:

Incorrect product formulations

Batch-to-batch quality variations

Misleading conclusions in scientific research

Calibration is not a simple comparison; it is a traceable metrological process. It strictly follows national or international regulations (e.g., JJG 1002 Rotational Viscometer, ASTM D445 Kinematic Viscosity) and requires reference to higher-accuracy standards such as certified silicone oil reference fluids, measured in a thermostatic bath under controlled conditions.

3. Key Performance Indicators in Calibration

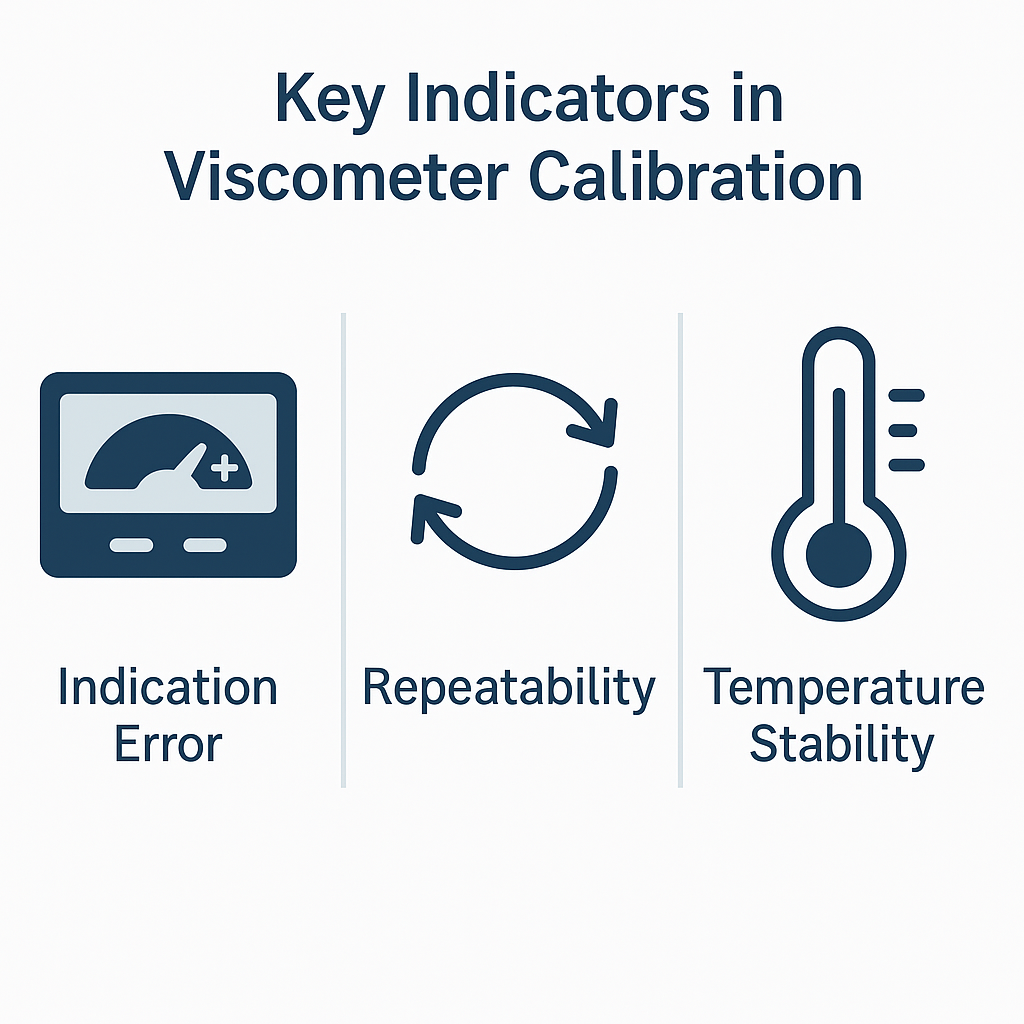

A complete calibration and verification cycle typically evaluates the following indicators:

Indication Error

Difference between the instrument reading and the reference standard value; the core measure of accuracy.Repeatability

Degree of consistency when measuring the same sample multiple times; reflects instrument stability.Reproducibility

Measurement consistency across different operators or conditions.Temperature Uniformity and Stability

Ensures the test environment eliminates temperature-related disturbances.

4. Best Practices for Calibration and Testing

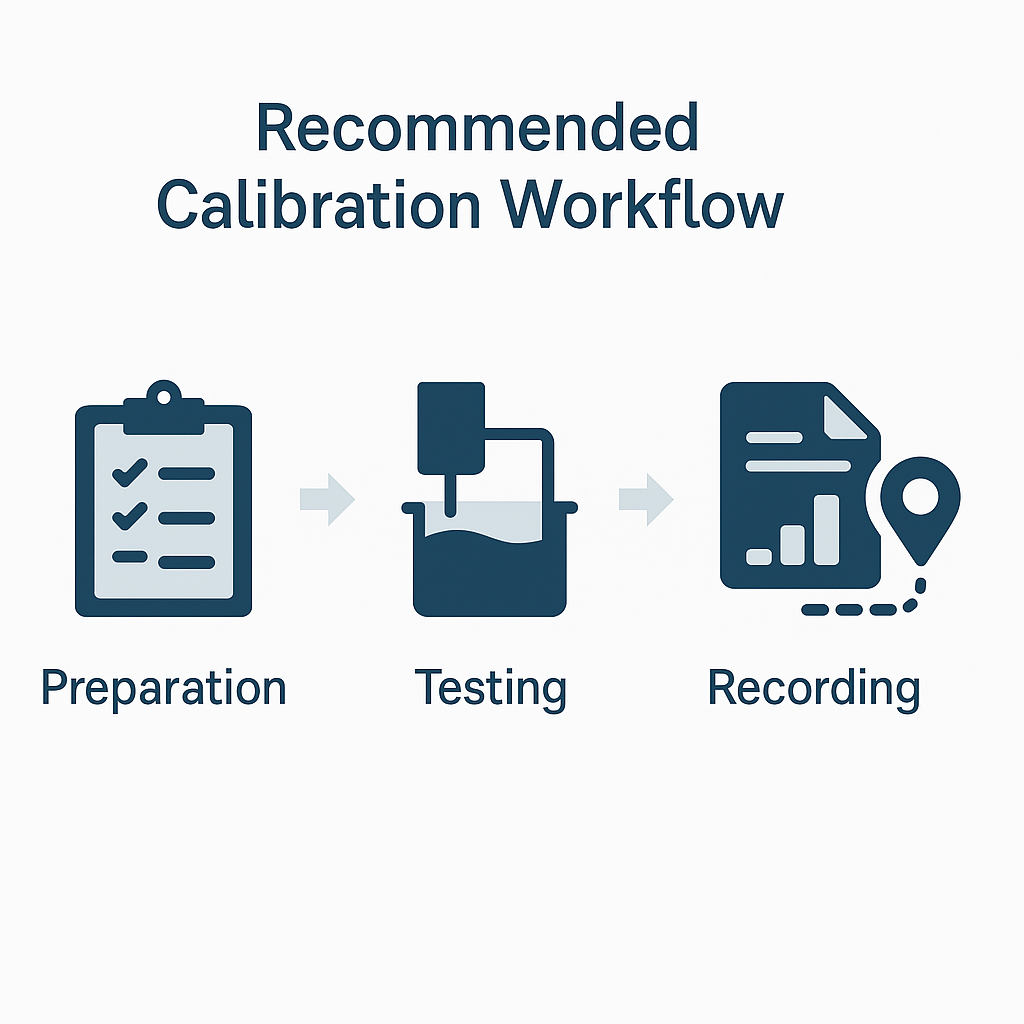

To ensure reliable viscosity measurement, laboratories and enterprises should adopt the following best practices:

Work Instructions

Establish detailed SOPs (Standard Operating Procedures) for calibration and testing.Traceability

Ensure standard reference fluids are traceable to national or international standards.Environmental Control

Precisely maintain temperature; viscosity is highly sensitive to even minor temperature variations.Comprehensive Records

Record calibration date, reference fluid properties, environmental conditions, results, and operator details to ensure full traceability.Risk-Based Scheduling

Define calibration intervals based on instrument usage intensity and application risk.

5. Benefits of Regular Calibration

Compliance with ISO, GMP, and other quality management systems

Prevention of hidden production risks and quality deviations

Improved competitiveness through reliable and reproducible data

Long-term cost savings by avoiding product recalls or research errors

6. Conclusion

Viscometers are precision instruments whose performance naturally drifts over time. Regular calibration and verification are the only scientific approach to guarantee trustworthy measurement data.

By implementing systematic calibration, traceability, and risk-based maintenance planning, enterprises can truly achieve “measure viscosity with precision” and safeguard product quality.