A radar level meter is a very advantageous instrument that is very reliable and trustworthy in measuring solid powders. When choosing level meters for measurement in various industries, the radar level meter is the target of choice, but when it comes to installation, many users are in trouble.

A radar level meter is a relatively precise instrument, there are many details that need to pay attention to when installing, otherwise, it is likely to cause a small link to inaccurate measurement or even can not measure the situation, so it is particularly important to master some tips for installing radar level meter.

The measuring principle of the radar level meter is important to know, it is based on the time travel principle of measuring instruments, radar waves run at the speed of light, and the running time can be converted into level signals through electronic components. When the pulse meets the material surface it is reflected and received by the receiver inside the meter, which converts the distance signal into a level signal.

The non-contact measurement of the radar level meter has great advantages because non-contact measurement almost avoids daily maintenance, damage, and material adhesion, and accessories do not need to be replaced, long service life, simple installation, and easy operation, it is now widely used in all walks of life.

So what are the techniques to be mastered by the account during installation? Installation needs to avoid the inlet, this is to prevent the falling material interference measurement echo, thus affecting the measurement. Also need to avoid vibration, high-pressure cleaning, and lateral load installation, to prevent damage to the radar level meter.

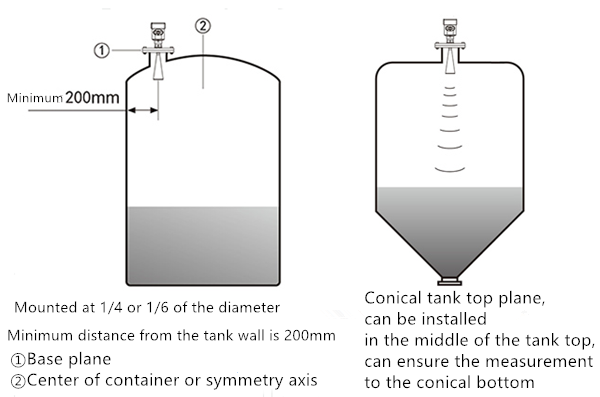

It is worth noting that if the radar level meter is installed in a tank with a conical bottom, the antenna must be aligned with the bottom of the tank so that false echoes can be avoided and the measurement is complete. It is also necessary to avoid objects that cause false reflections in the emission angle, such as ladders, cross tubes, etc., in the nearest 1/3 cone emission area from the antenna, because the closer the obstacle, the stronger the false emission signal, previously we have shared relevant cases is that there are obstacles that lead to inaccurate measurement.

We also need to pay attention to the measurement of dust concentration and material humidity of the material level on the occasion of the installation of a dust cover or blowing device, so that the probe will not cause inaccurate measurement results because of the accumulation of dust.

Finally, we would like to share that when detecting high material level, the distance between the probe and the material surface should not be less than 1m, and the end of the probe antenna should be able to extend the container receiver so that the best effect of measurement can be achieved.