The accuracy of measuring instruments directly impacts the quality of a company’s production processes and final products. In manufacturing enterprises, managing these instruments effectively is crucial to ensuring quality control. However, given the sheer volume of measuring instruments—sometimes numbering in the hundreds or thousands—their calibration, maintenance, and management pose significant challenges, especially in medium-to-large-scale manufacturing settings. This article introduces the ABCD Classification Method, a practical framework for scientifically and efficiently managing measuring instruments.

Challenges in Managing Measuring Instruments

In manufacturing industries, measuring instruments are used daily and are subject to wear and tear. Ensuring their accuracy requires regular calibration, maintenance, and upkeep. For large factories with diverse and numerous devices, inefficient management can lead to operational risks, including production delays, defective products, and regulatory non-compliance. This makes it critical to implement a systematic approach that prioritizes resources while ensuring all instruments meet operational and compliance standards.

What Is the ABCD Classification Method?

The ABCD Classification Method categorizes measuring instruments into four distinct classes (A, B, C, and D) based on their usage, importance, and required maintenance levels. Each category has specific management requirements to streamline efforts while maintaining efficiency.

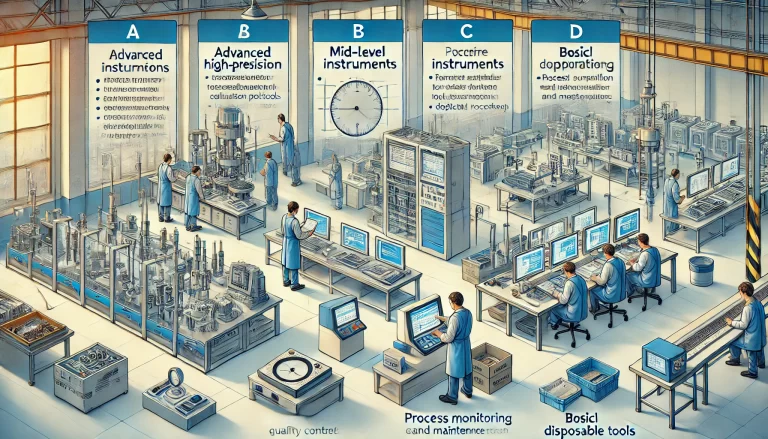

Class A: Enterprise’s Highest Measuring Standards

Class A instruments represent the highest standard of measurement within the enterprise. They are typically approved by government regulatory bodies and are often used for purposes such as trade settlement, safety protection, environmental monitoring, and healthcare.

Management Requirements:

Documentation: Establish comprehensive records for each instrument, ensuring one-to-one correspondence between physical devices and their documentation.

Mandatory Periodic Inspection: Develop and implement strict periodic verification plans to maintain compliance with regulations.

Dedicated Management: Assign specific personnel to oversee the usage of these instruments and prohibit usage beyond their validity period.

Regular Internal Inspections: Employ specialized staff to conduct routine maintenance and inspections in accordance with relevant procedures.

Marking Compliance: Ensure all instruments display appropriate calibration marks or compliance labels.

Class B: Internal Value-Tracking Instruments

Class B instruments are essential for internal quality control, including secondary and tertiary energy measurement. These instruments are critical for ensuring consistency but may not fall under government-mandated calibration.

Management Requirements:

Comprehensive Records: Maintain accurate and up-to-date documentation for each instrument.

Calibration Plans: Follow national or industry calibration guidelines for periodic inspection or calibration.

Usage Monitoring: Assign personnel to supervise usage and ensure compliance.

Maintenance Protocols: Perform routine internal inspections to maintain operational integrity.

Labeling: Apply verification or calibration labels to all instruments.

Class C: Process Control Instruments

Class C instruments are used primarily for production process monitoring and control. They are critical to maintaining process parameters and ensuring product consistency.

Management Requirements:

Simplified Records: Establish basic documentation for key instruments and verify data periodically.

Flexible Calibration: Adjust calibration cycles based on company needs, within the limits of national or industry standards.

Real-Time Monitoring: Ensure real-time supervision of instrument conditions to prevent misuse.

Routine Maintenance: Conduct scheduled maintenance to ensure proper functioning.

Label Compliance: Confirm all instruments have appropriate calibration or inspection labels.

Class D: General and Disposable Instruments

Class D instruments are low-value, short-lived tools primarily used for simple measurements. They often have stable performance and do not require strict calibration.

Management Requirements:

Basic Recordkeeping: Allow departments to maintain simple records or inventories without centralized oversight.

Inspection at Entry: Focus on quality verification during procurement and acceptance stages.

User Accountability: Delegate proper usage and condition checks to individual users or departments.

Flexible Management: Exclude these instruments from mandatory calibration requirements.

Advantages of the ABCD Classification Method

By implementing the ABCD Classification Method, enterprises can optimize their resource allocation and enhance efficiency. Key benefits include:

Prioritization of Resources: Focus on high-priority instruments (A and B classes) while simplifying the management of low-priority tools (C and D classes).

Improved Efficiency: Clear classification reduces unnecessary redundancy and ensures critical instruments receive proper attention.

Regulatory Compliance: Maintain compliance with government regulations for essential instruments.

Cost Optimization: Minimize resource waste by tailoring management strategies to each category.

Enhanced Decision-Making: Use data from instrument management to refine maintenance schedules and calibration cycles.

Practical Implementation Tips

Leverage Technology: Use digital tools or software to maintain records, schedule calibrations, and track instrument status.

Train Staff: Educate personnel on the classification system and their responsibilities within it.

Periodic Review: Regularly review the classification of instruments to account for operational changes.

Case Studies and Benchmarking: Learn from other companies that have successfully implemented similar frameworks.

Conclusion

The ABCD Classification Method provides a structured and efficient way to manage measuring instruments, particularly in manufacturing settings with high instrument volumes. By categorizing instruments based on their importance and usage, enterprises can improve operational efficiency, ensure quality, and achieve better compliance. Implementing this method not only optimizes resource use but also supports long-term organizational goals. For enterprises looking to enhance their measuring instrument management practices, adopting the ABCD Classification Method is a step towards greater precision and efficiency.