In industrial instrumentation, theoretical knowledge is just like a wrench in your toolbox — it may not seem important at first glance, but when troubleshooting, it becomes indispensable. Whether preparing for certification exams or improving practical fieldwork, mastering instrumentation theory helps build a solid foundation. This document highlights several core concepts that often cause confusion in practice.

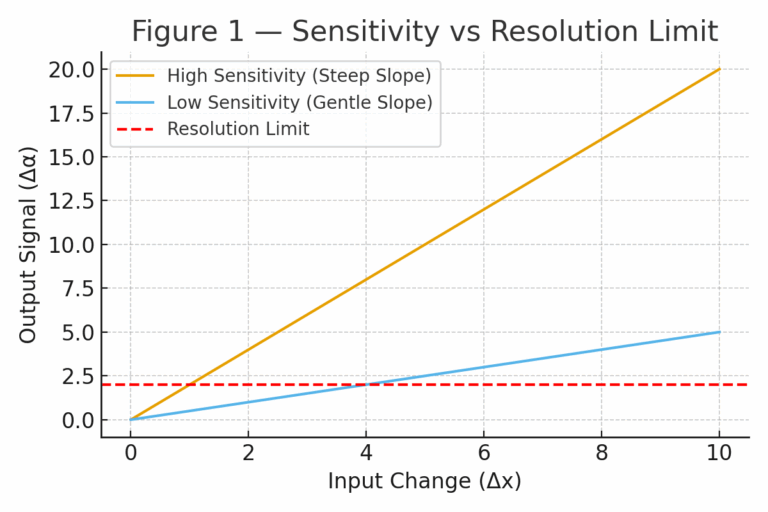

1. Sensitivity vs. Resolution Limit

Some people mistakenly believe that sensitivity is the same as the resolution limit. This is incorrect.

Sensitivity (S)

S=ΔxΔα

Sensitivity expresses how strongly an instrument responds to changes in the measured parameter. It is defined as:where Δα = change in instrument output signal, and Δx = change in input signal.

Sensitivity corresponds to the slope of the input-output transfer curve.Resolution Limit

The resolution limit refers to the smallest change in the input signal that produces a detectable change in the instrument output. Typically, this value should not exceed half of the permissible error of the instrument.

🔎 Conclusion: Sensitivity and resolution limit both describe how “responsive” an instrument is, but they are different parameters.

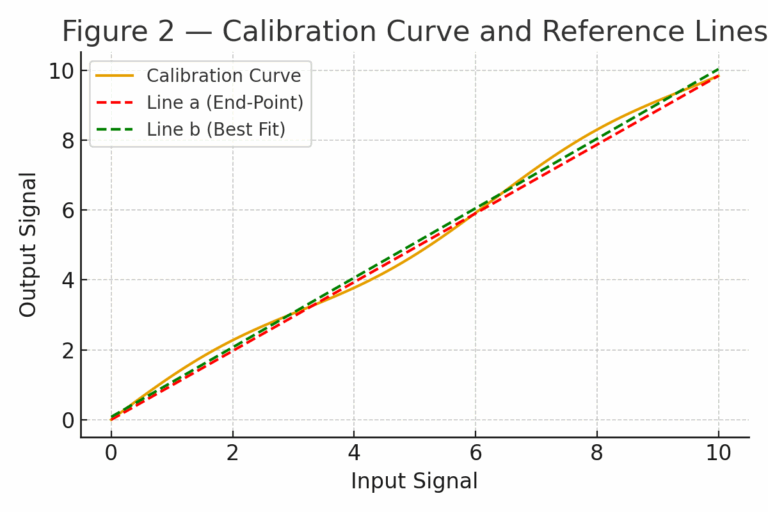

2. Nonlinearity Error and Reference Line Selection

When evaluating an instrument’s calibration curve, nonlinearity error is measured as the maximum deviation between the curve and a reference straight line. Two common reference lines exist:

End-Point Line (Line a): Connects the upper and lower calibration limits → defines terminal-based linearity error.

Best-Fit Line (Line b): Minimizes the maximum deviation → defines independent linearity error.

In practice, independent linearity error (Line b) is more representative because it better reflects actual error sources and corrective actions.

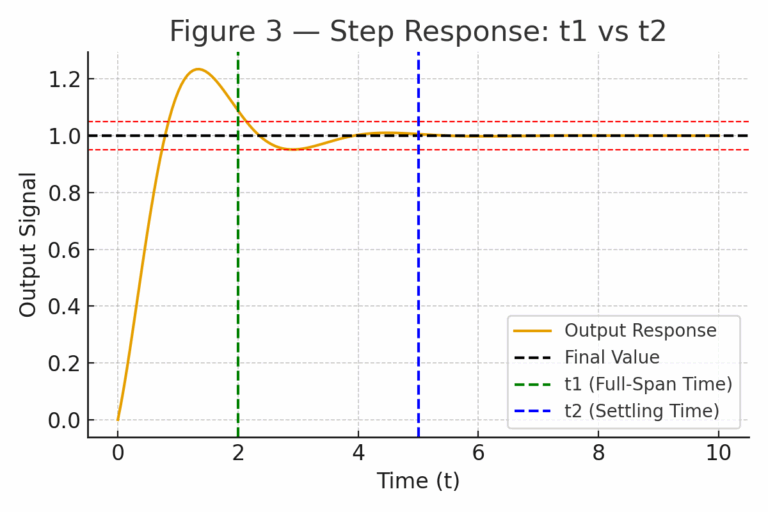

3. Settling Time vs. Full-Span Response Time

Settling Time (t₂):

Time from a step input until the output signal remains within a specified tolerance band (e.g., ±5%) of the final steady-state value.Full-Span Response Time (t₁):

Time for the output to first reach the difference between the initial and final steady-state values (typically at 10%, 5%, or 1% criteria).

🔎 Key Point: Settling time and full-span response time are not identical; both must be considered in dynamic performance testing.

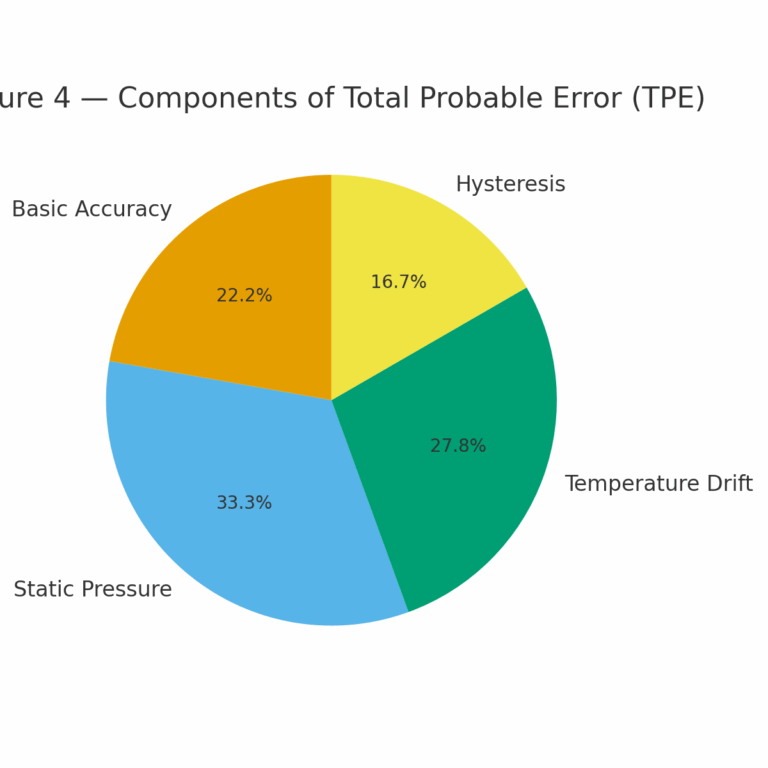

4. Why Total Probable Error (TPE) is More Representative

Instrument accuracy is usually specified under reference conditions (e.g., 20 ± 1 °C, 0.1 MPa). However, field conditions rarely match reference conditions. For example, a differential pressure transmitter may operate at tens or even hundreds of bar, with wide temperature variations.

Therefore, a more realistic performance metric is Total Probable Error (TPE):

TPE=∑ei2

where eᵢ represents additional error sources (static pressure, temperature, hysteresis, etc.).

🔎 Conclusion: TPE provides a better representation of real-world measurement accuracy than the nominal accuracy class.

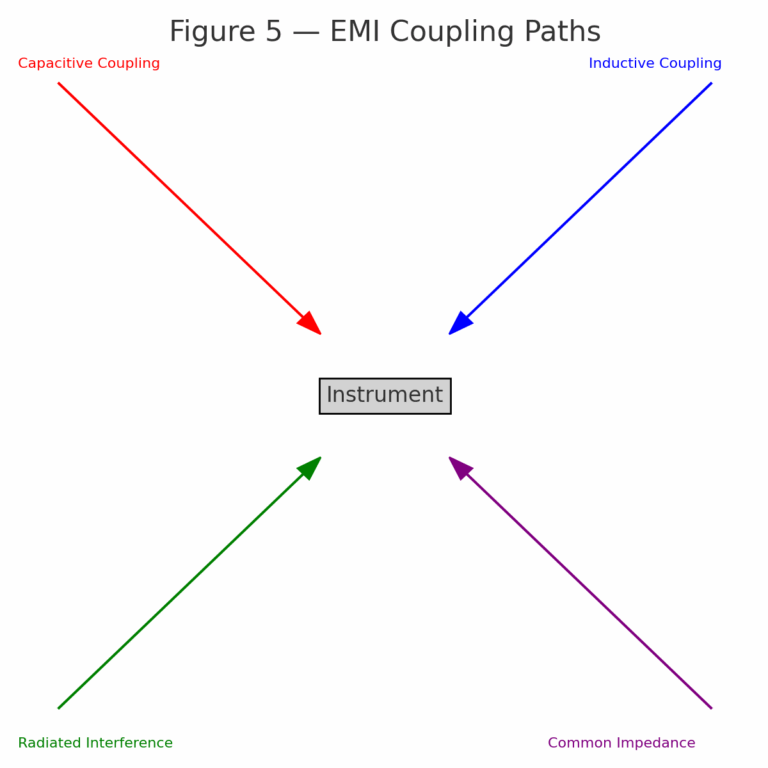

5. Electromagnetic Compatibility (EMC) Standards

Industrial instruments often operate in environments filled with electromagnetic interference (EMI) from devices such as:

Switchgear and relays

Welding machines

Broadcasting and telecommunication systems

Industrial and medical equipment

Even static-charged personnel

Electromagnetic Compatibility (EMC) defines an instrument’s ability to function normally without introducing unacceptable disturbances to its environment. EMC requirements consist of:

Immunity: Ability to withstand external electromagnetic interference.

Emission Limits: Restrictions on electromagnetic disturbances generated by the instrument.

🔎 Practical Note: Because modern process instruments are mostly electronic and microprocessor-based, they must undergo EMC testing (conducted interference, radiated interference, ESD) to ensure compliance.

📌 Conclusion

Understanding and distinguishing between sensitivity, resolution limit, nonlinearity, settling time, TPE, and EMC is essential for both theoretical study and practical troubleshooting. By strengthening these foundations, engineers can significantly improve fault diagnosis efficiency and avoid costly misjudgments.