1. General Requirements

The installation and use of pressure gauges, safety valves, level gauges, and thermometers shall comply with the Regulations on Safety Technical Supervision of Pressure Vessels.

The calibration and maintenance of pressure gauges shall comply with relevant national metrology regulations. Pressure gauges must be calibrated prior to installation, with the maximum working pressure marked in red on the dial, and the next calibration date clearly indicated.

2. Calibration and Certification

Pressure gauges and thermometers must undergo calibration before use. After calibration, an inspection label shall be affixed to the instrument, and the calibration certificate shall be properly filed and archived.

Pressure gauges and thermometers shall be recalibrated every six months. The calibration work is the responsibility of the equipment administrator.

3. Conditions Requiring Withdrawal from Service (Pressure Gauges)

A pressure gauge must be immediately removed from service for recalibration or replacement if any of the following conditions occur:

For gauges with a stop pin: the pointer cannot return to zero when not under pressure.

For gauges without a stop pin: the pointer deviates from zero beyond the allowable error.The dial cover glass is broken or the dial is unclear.

The seal is broken or the calibration validity period has expired.

Leakage of the Bourdon tube or looseness of the pointer.

Pointer breakage or severe corrosion of the case.

Any other defect affecting the accuracy of pressure indication.

Note: Replacement pressure gauges must also be calibrated prior to installation.

4. Conditions Requiring Replacement (Level Gauges)

A level gauge must be taken out of service and replaced under any of the following conditions:

Glass plate cracked or broken.

Valves stuck or jammed.

Indication of false liquid level.

Blurred or unclear level indication.

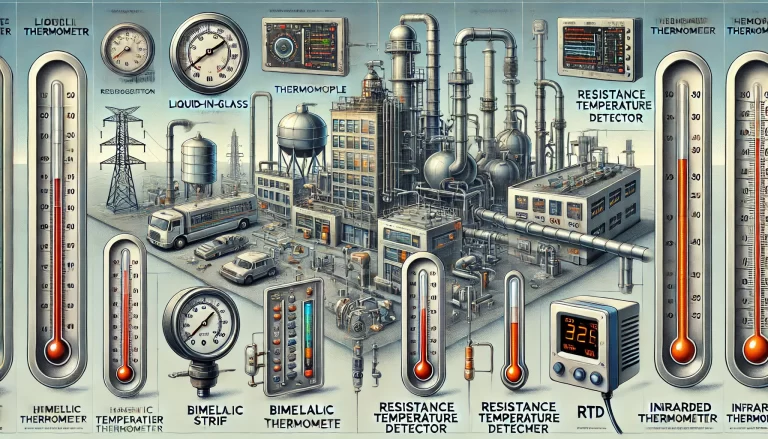

5. Temperature Measuring Instruments

Temperature measuring instruments (e.g., thermometers, RTDs, thermocouples) must not be used without a valid calibration certificate or if they exceed the permitted calibration interval.