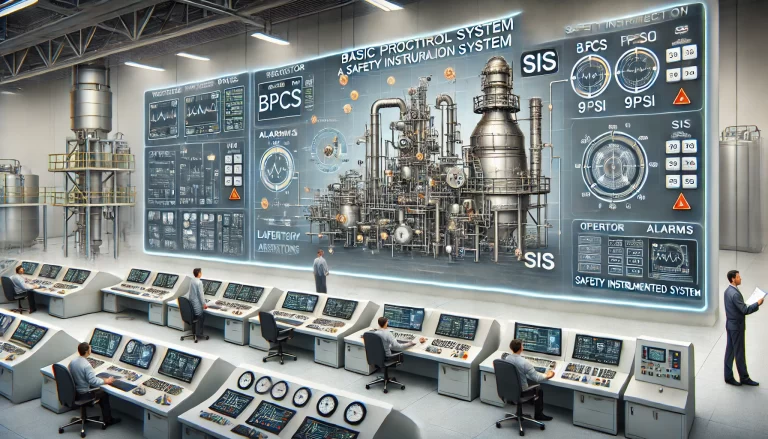

The Safety Instrumented System (SIS) plays a critical role in industrial safety by implementing Safety Instrumented Functions (SIF) to prevent or mitigate hazardous events. Effective management, routine maintenance, and proper fault handling are essential to ensure SIS functionality and system integrity. This article outlines detailed best practices and requirements across these three aspects.

1. Management Requirements

1.1 Complete and Accurate Documentation

All SIS-related documents, including original construction data, product manuals, operation guides, configuration records, and change logs, must be complete, accurate, and up-to-date.

1.2 Controlled Activation/Deactivation of SIF

Temporary or long-term deactivation, as well as reactivation of any SIF, must follow an approved management procedure.

Risk assessments must be performed, work permits must be issued, and safety confirmations must be completed before any action.

Specific Procedures:

Before deactivating a SIF, coordinate with process operators and verify the bypass status.

Verify bypass switch and loop consistency with at least two personnel checking against design drawings.

Before reactivating a SIF, process and instrumentation personnel must jointly verify proper functionality. For memory-retentive loops, reset logic states to reflect current operating conditions. For sequential or special logic loops, confirm reactivation conditions per the loop logic diagram.

1.3 Change Management

Any modification to the SIS—such as wiring, sensor elements, logic programs, setpoints, or alarm limits—must go through a formal approval process.

All changes must be documented, and system diagrams updated accordingly.

1.4 New Installations and Modifications

Safety function changes during new construction or system retrofitting must include corresponding SIS design documents and should be implemented simultaneously with the project.

2. Maintenance Requirements

2.1 Routine Inspections

Periodically inspect and clean SIS cabinets and filters to maintain environmental compliance.

Power supply and instrument air systems must be maintained according to system-specific maintenance standards.

2.2 Device-Level Maintenance

Sensors and final elements must be maintained per their respective equipment manuals.

Logic controllers should be functionally tested at regular intervals.

2.3 Explosion-Proof Components

Maintain explosion-proof sensors and actuators in accordance with the explosion protection maintenance protocol.

2.4 System and Visual Checks

Regularly test indicator lights, buzzers, and silence buttons.

Check module status on the SIS main panel for abnormalities.

Inspect terminals, cables, sample lines, and enclosures for damage or wear.

Verify trace heating, solenoid valve shell temperature, and waterproofing conditions for pressure signal lines.

2.5 Data Validation and Alarm Review

Regularly analyze SIS alarms and process trends to assess the logic response and program status.

2.6 Fault Response

Any anomalies must be reported and resolved promptly. For critical issues, notify responsible personnel, perform risk assessments, and carry out repairs only after proper approvals.

2.7 Documentation and Spare Parts

Maintain complete drawings, loop setpoint tables, change records, and essential spare parts inventory.

2.8 Maintenance Records

Maintain inspection and maintenance logs as the basis for fault analysis and preventive maintenance planning.

3. Maintenance and Fault Handling Procedures

3.1 Daily Maintenance

3.1.1 Cleaning and Environmental Control

Clean SIS cabinets, HMI workstations, engineering stations, printers, keyboards, and filters regularly to maintain proper operating conditions.

3.1.2 Routine Patrol Checks

Include the following:

Environmental Conditions: Room temperature and humidity.

Power Supply Status: Ensure stability and compliance.

Controller Health: Module status, system logs, alarm history, SOE logs.

Cybersecurity: Regular password changes, backups with offsite storage.

Traceability: Record all inspection results systematically.

3.1.3 Software and Security Updates

Regularly collect and implement SIS patches, version updates, and antivirus definitions.

Check and update application whitelisting as needed.

3.1.4 Setpoint and Override Handling

Any manual override or setpoint changes must be approved in advance.

All changes must be recorded, and overrides should be removed as soon as practical.

3.1.5 Logic Modifications

Any application download or program modification must be pre-approved.

Use a test-then-deploy strategy. Backups must be created before and after modifications.

3.2 Fault Handling

3.2.1 General Guidelines

Before troubleshooting any SIS loop, deactivate the relevant SIF and prepare a detailed work plan with proper approvals to prevent secondary incidents.

3.2.2 Device-Level Faults

Refer to the maintenance manual for specific fault procedures.

During actuator loop fault resolution, ensure the actuator remains in a safe state.

3.2.3 Loop Troubleshooting

Verify terminal connections, wire insulation resistance, and junction box integrity.

3.2.4 Logic Module Replacement

Replacement modules must match the original in model, version, and configuration.

Follow product manuals and standard operating procedures strictly.

3.2.5 Power Supply Maintenance

Isolate the circuit before replacing DC power units. Post-replacement, check and adjust output voltage.

3.2.6 Workstation Reinstallation

Reinstall engineering or operator stations using the same software version and configurations.

Verify all communication port settings post-installation.

3.2.7 Fault Logging

Collect system diagnostic files and SOE data.

Record the serial numbers, fault details, and maintenance actions for traceability.

Conclusion

An effective SIS program is not just about selecting the right technology, but about establishing robust management, maintenance, and troubleshooting practices. Proper documentation, regular inspections, timely updates, and a well-defined change management workflow ensure safety, reliability, and long-term system performance.