Introduction

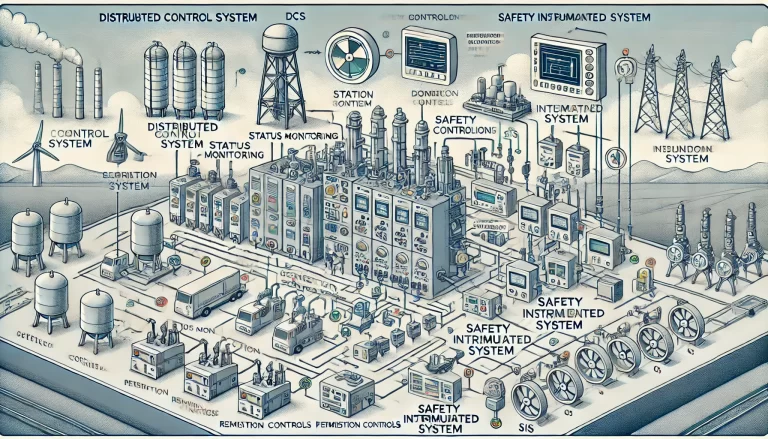

Distributed Control Systems (DCS) are pivotal in managing industrial processes safely and efficiently. Graded alarm control technology ensures that alarms in different zones are independent, using dedicated detectors for each area. This facilitates timely alerts when anomalies occur, drawing operators’ attention and preventing accidents. This document outlines the application, principles, and management strategies for DCS alarm systems, particularly in hazardous chemical production environments, to enhance safety and operational stability.

1. Overview of the DCS Multi-layer Graded Control System

1.1 Design Philosophy

The DCS is designed with decentralized control and centralized operation/management. This approach allows for multilayer graded control and coordination, with applications spanning metallurgy, power generation, and petrochemical industries.

1.2 Core Components

Field Control Units (FCUs):

- Positioned near the operation site, FCUs manage on-site monitoring and control.

- They require specific hardware configurations, such as central processing unit (CPU) plugins, power modules, and communication interfaces, to enable redundancy and reliability.

- FCUs ensure real-time, localized control and data acquisition.

Operator Stations:

- These serve as interfaces for human-machine interaction, featuring system controllers, display units, and input devices.

- Key functions include real-time data visualization, alarm notifications, and manual intervention options.

2. Application of Graded Alarm Technology

2.1 Toxic and Hazardous Gas Alarms

Modern DCS alarm systems are tailored for detecting toxic, harmful, and flammable gases. To maintain system efficiency, alarm devices must adhere to strict selection criteria:

- Capable of providing power to detectors and communication components.

- Emit persistent and noticeable signals until acknowledged.

- Monitor gas concentrations within explosive or hazardous limits.

- Include features such as fire protection and interlocking safety mechanisms.

2.2 Key Operational Parameter Alarms

To minimize operational risks, critical parameters (e.g., pressure, temperature) must be accurately defined and monitored.

- Pop-up Alerts: Alarms should display prominently on the central screen, enabling immediate attention and response.

- Voice Alarms: Pre-recorded audio notifications should be configured for potential scenarios, improving response times.

3. DCS Alarm Grading Principles

3.1 Alarm Levels

DCS alarms are classified into four levels based on their impact severity:

- Level 1 (Critical): Immediate threats, such as fire, explosions, or toxic leaks exceeding safe thresholds.

- Level 2 (Severe): Alarms indicating significant deviations or secondary system failures.

- Level 3 (Moderate): Alarms indicating minor process deviations or equipment faults.

- Level 4 (Advisory): Non-critical notifications such as equipment start/stop status.

3.2 Alarm Settings

New system installations or process changes must undergo collaborative reviews involving process, instrumentation, and safety teams. Alarm configurations, including thresholds and notification modes, should be documented and updated regularly.

4. Alarm Management Workflow

4.1 Alarm Configuration and Updates

- Changes must follow a formal approval process, ensuring alignment with operational safety standards.

- Updated configurations must be thoroughly tested before deployment.

4.2 Alarm Display and Dissemination

- Alarms should feature clear visual and auditory cues, e.g., red flashing lights and high-pitched tones for critical alerts.

- Alarm data must be shared across relevant departments through networked dashboards and mobile devices.

4.3 Alarm Acknowledgment and Handling

- Operators must acknowledge alarms within defined timeframes, investigate root causes, and initiate appropriate responses (e.g., emergency shutdowns for Level 1 alarms).

- Handling actions and outcomes should be logged for future review.

4.4 Alarm Resolution

After resolving issues, alarms should only be deactivated when parameters have stabilized for a defined period (e.g., 10-30 minutes). Persistent or frequent alarms should trigger detailed analyses by relevant teams.

5. Performance Monitoring and Continuous Improvement

5.1 Monthly Alarm Data Analysis

- Metrics such as frequency, duration, and root causes of alarms should be analyzed and compiled into reports.

- Findings should inform system optimizations, such as adjusting thresholds or improving equipment reliability.

5.2 Training and Education

- Comprehensive training programs should cover system basics, alarm grading principles, and emergency handling.

- Regular workshops and case studies should reinforce operators’ skills and knowledge.

5.3 Evaluation and Incentives

- Alarm management performance should be linked to departmental KPIs.

- Reward outstanding contributors and address lapses through structured feedback and disciplinary measures.

6. Enhancing Future Capabilities

6.1 Emerging Technologies

Future iterations of DCS systems can incorporate AI for predictive analysis and advanced sensors to further enhance alarm precision and efficiency.

Conclusion

Effective DCS alarm management is foundational to industrial safety and operational efficiency. By adhering to the principles outlined in this document, organizations can mitigate risks, ensure regulatory compliance, and foster a culture of continuous improvement.