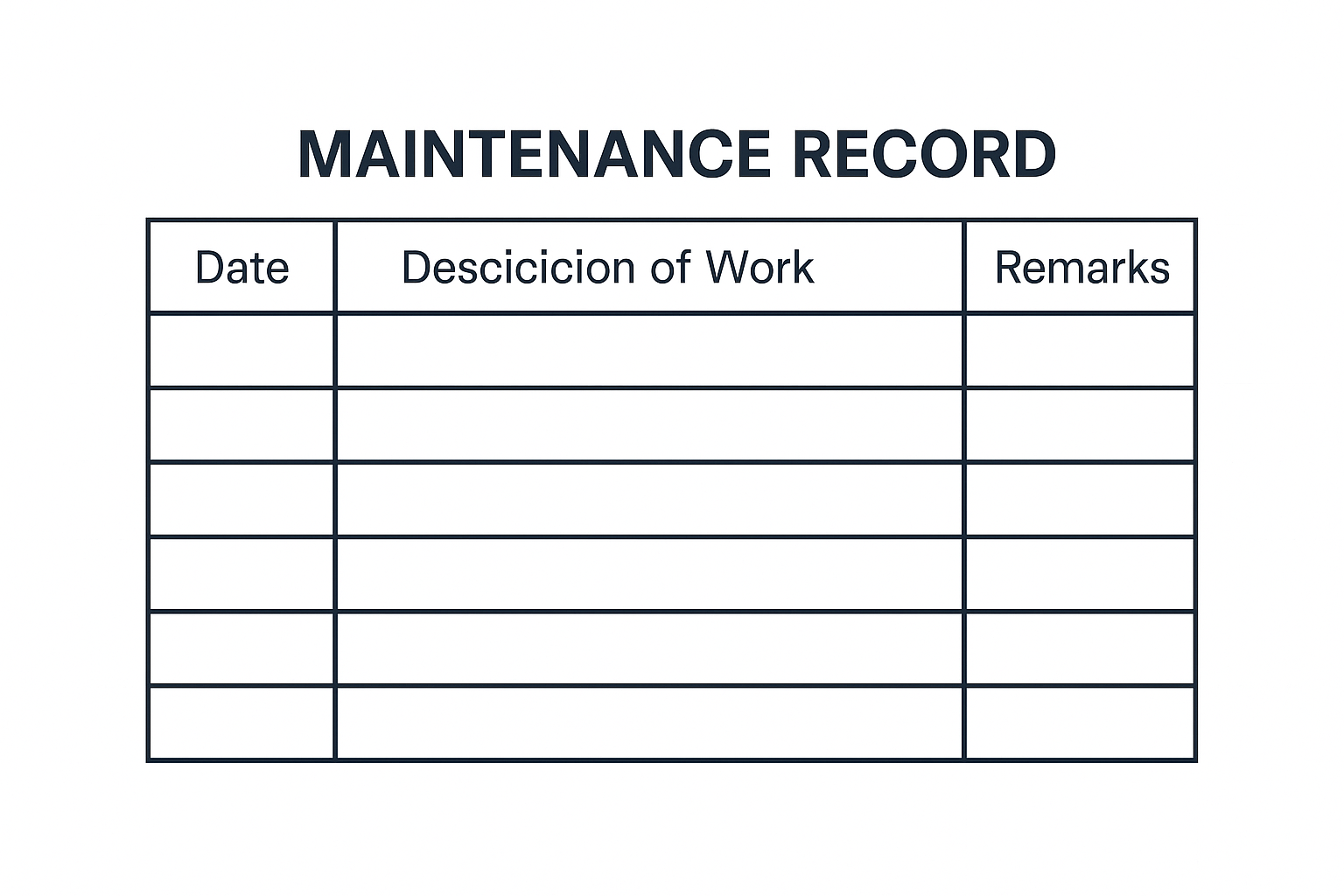

1. Overview of Orifice Flowmeters

Orifice flowmeters, also known as differential pressure flowmeters, consist of a primary element (such as an orifice plate, nozzle, or Venturi tube) and a transmitter.

Special types like quarter-circle orifice plates, segmental orifice plates, and double orifice plates are used for specific applications. Depending on the fluid characteristics (e.g., corrosive, viscous, or gas-bearing), additional components such as seal pots or elevated transmitter positions may be required.

Illustration 1: Typical Configuration of Orifice Flowmeter (with DP transmitter)

2. Key Steps for Maintenance and Retrofitting

2.1 Pre-Operation Preparation

Process Confirmation:

Coordinate with process department to confirm that dismantling does not trigger interlocks.

Apply for work permits, including high-altitude operation permits if required.

Risk Assessment:

Evaluate pressure, temperature, and corrosiveness.

Use protective gear (e.g., gloves, goggles).

For flammable/explosive media, use explosion-proof tools. Always work in pairs for safety.

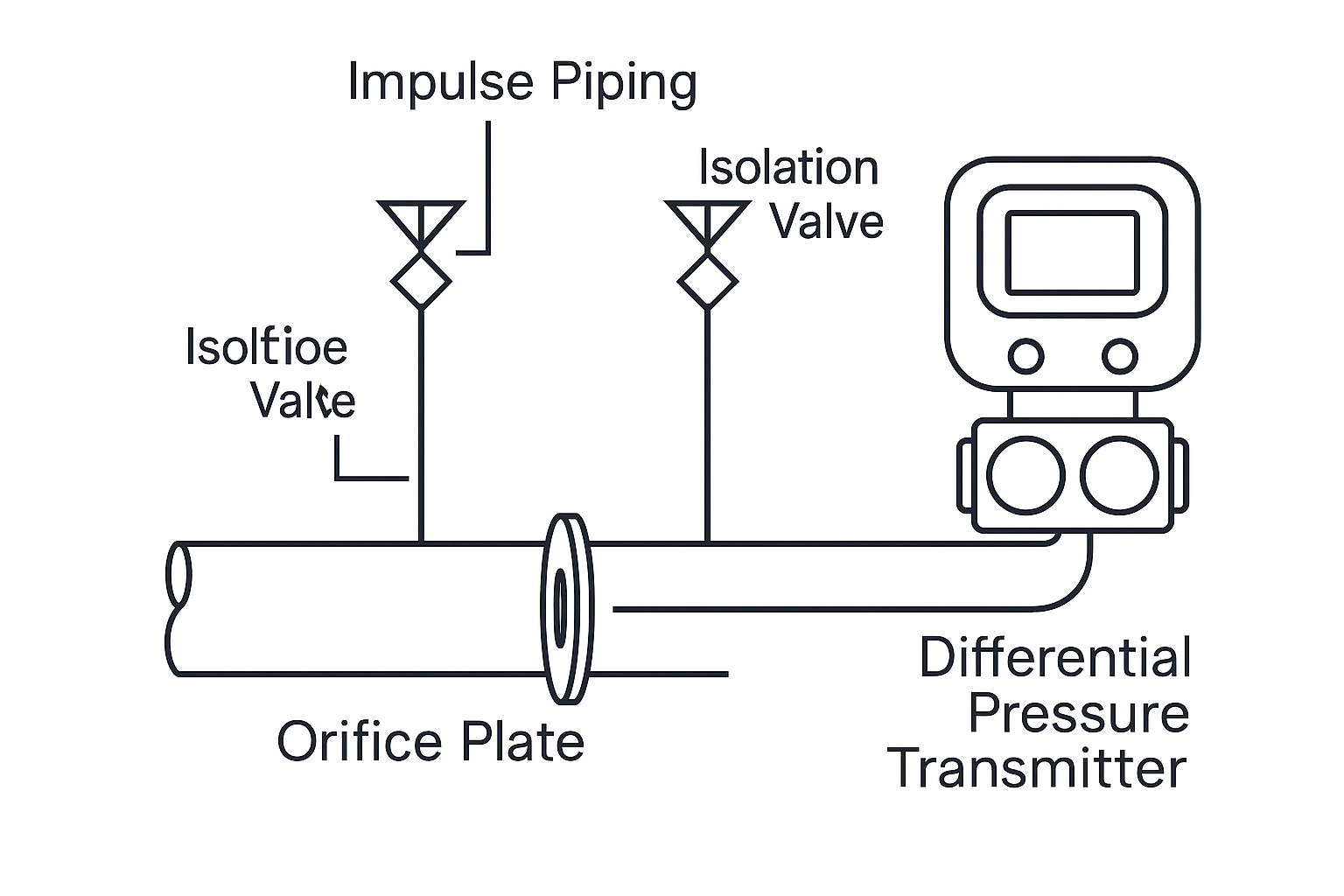

2.2 Visual Inspection Checklist

| Component | Inspection Items |

|---|---|

| Impulse Tubes & Valves | Check for corrosion, valve handle integrity, and drain valve blockages |

| Transmitter | Cleanliness, dryness, terminal corrosion, waterproof sealing, display status |

| Heat Tracing/Insulation | Operational status, rewrap insulation after repair |

Illustration 2: Inspection Points of Orifice Flowmeter System

2.3 Maintenance Points

Orifice Element Cleaning:

Gently clean after removal. Do not use abrasive tools such as sandpaper or files.

Corrosion & Erosion:

Replace if material mismatch or erosion is severe.

Investigate cause of deformation (e.g., stress, improper installation).

Pressure Tapping:

Ensure no blockage in pressure taps or annular chambers. Clean using steam or wire.

Sealing Surfaces & Accessories:

Inspect and record condition of bolts, gaskets, and flanges. Replace if damaged.

2.4 Pressure Testing

With Seal Liquid Systems:

Test for internal leaks, blockage, and joint integrity using seal liquid.

Pressure range: 4.0–5.0 MPa. Do not exceed valve ratings (usually 6.3 MPa).

Without Seal Liquid:

Use manual test pump or compressed air. Ensure system is leak-free.

2.5 Installation Notes

Sealing and Bolting:

Replace gaskets, optionally wrap PTFE tape.

Use elliptical gaskets for high-temp/pressure.

Align flanges and tighten bolts uniformly.

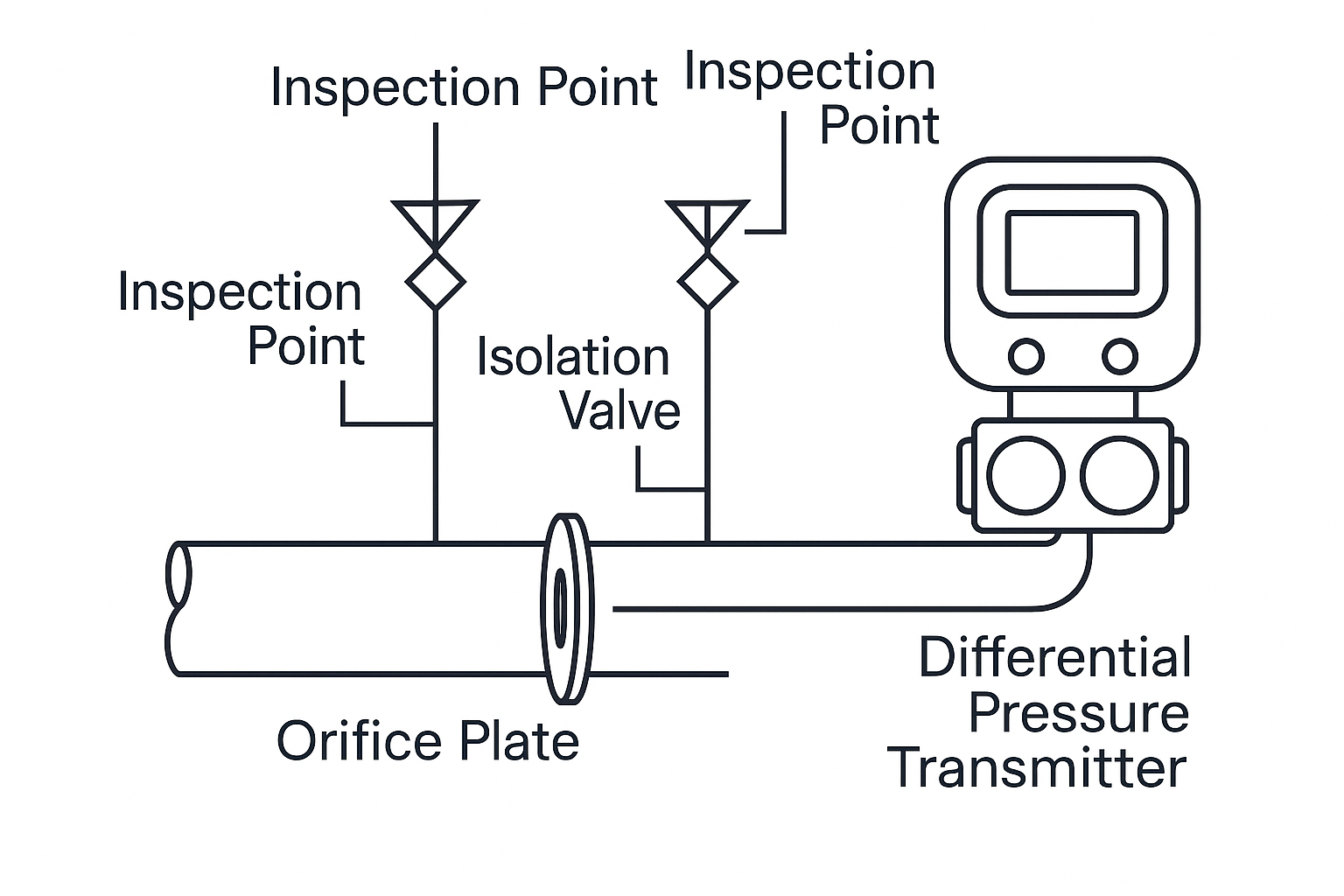

Transmitter Wiring:

Clean terminals. Replace damaged flexible tubing with cable glands.

Configure parameters (e.g., zero, square root extraction, low cut-off).

Illustration 3: Proper Wiring and Seal Protection on Transmitters

2.6 Final Pressure Test

Perform system-wide pressure test after reassembly.

Commission only after confirming no leakage.

3. Key Risks and Preventive Measures

| Risk Point | Preventive Measure |

| Media Leakage | Perform thorough pressure tests; replace aging gaskets and bolts |

| Transmitter Damage | Control pressure below rated limits; ensure proper sealing & wiring |

| Fall Hazards | Always wear safety belts during high-altitude tasks |

| Interlock Trigger | Confirm with process team before dismantling |

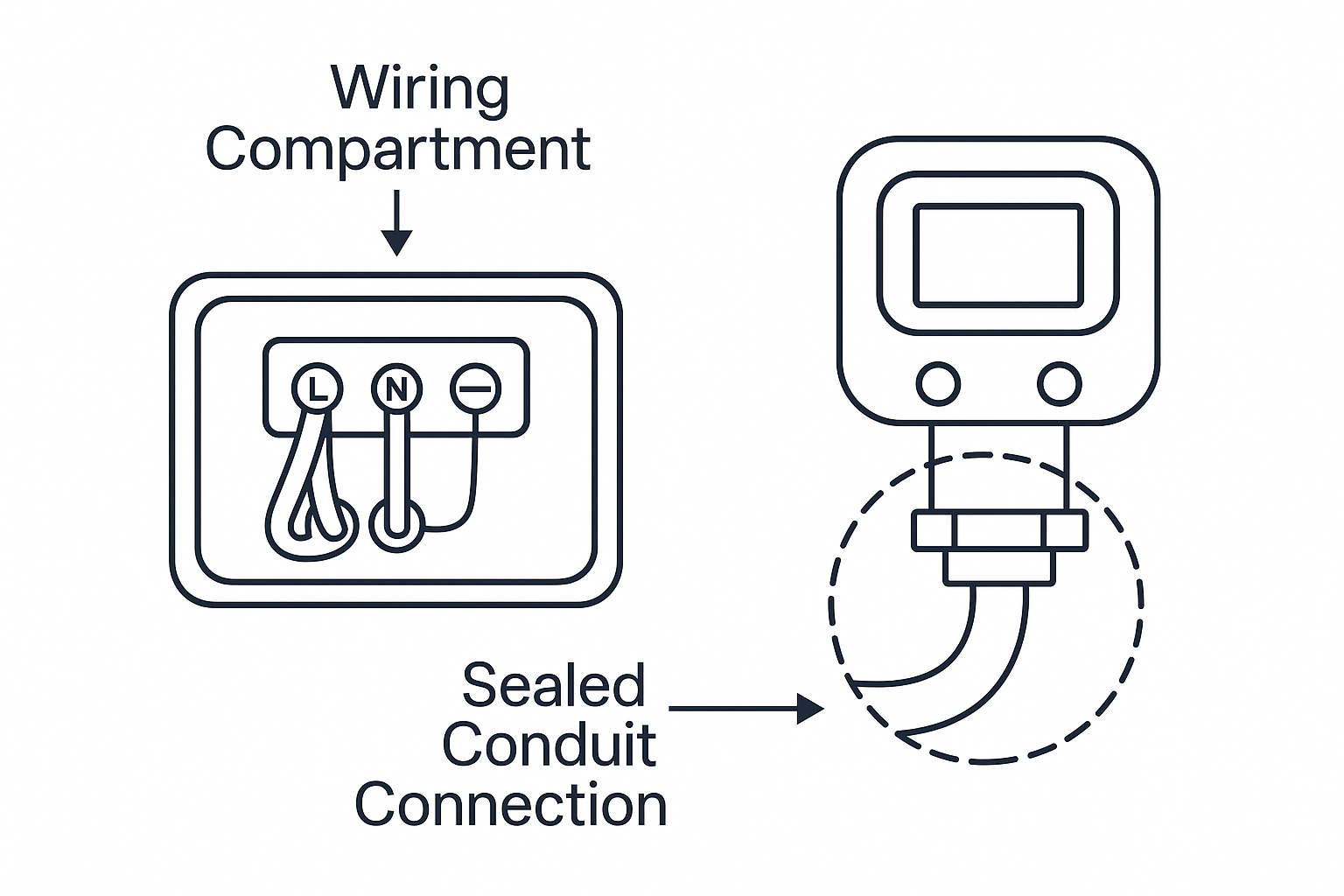

4. Maintenance Records

Document all inspections and repairs, including:

Type and extent of damage

Component replacement specifications

Remedial actions taken

Maintaining comprehensive records ensures traceability and supports continuous improvement in maintenance quality.

Illustration 4: Maintenance Record Template Sample