Electromagnetic flowmeters are widely used in industrial processes for their accuracy, stability, and ability to measure conductive fluids. However, like all precision instruments, proper maintenance is essential to ensure long-term performance and reliability. This article outlines key maintenance tasks for electromagnetic flowmeters, including electrode cleaning, anti-corrosion care, routine inspection, and recalibration.

1. Electrode and Liner Cleaning

Why it matters:

Over time, conductive deposits or scaling may accumulate on the inner wall of the flow tube or on the electrodes. This can lead to zero drift, increased noise, or even signal short-circuits.

Recommended action:

Periodically clean the internal wall and electrodes of the flow tube using suitable cleaning agents or procedures appropriate for the medium. Avoid abrasive tools that may damage the protective lining.

2. Instrument Surface Cleaning

Why it matters:

Dust, oil, or moisture on the exterior of the instrument can affect readability and operation, especially for local displays and push-button interfaces.

Recommended action:

Wipe the instrument’s enclosure, junction box, and display regularly with a clean, dry or slightly damp cloth. Keep vent plugs and labels visible and clean.

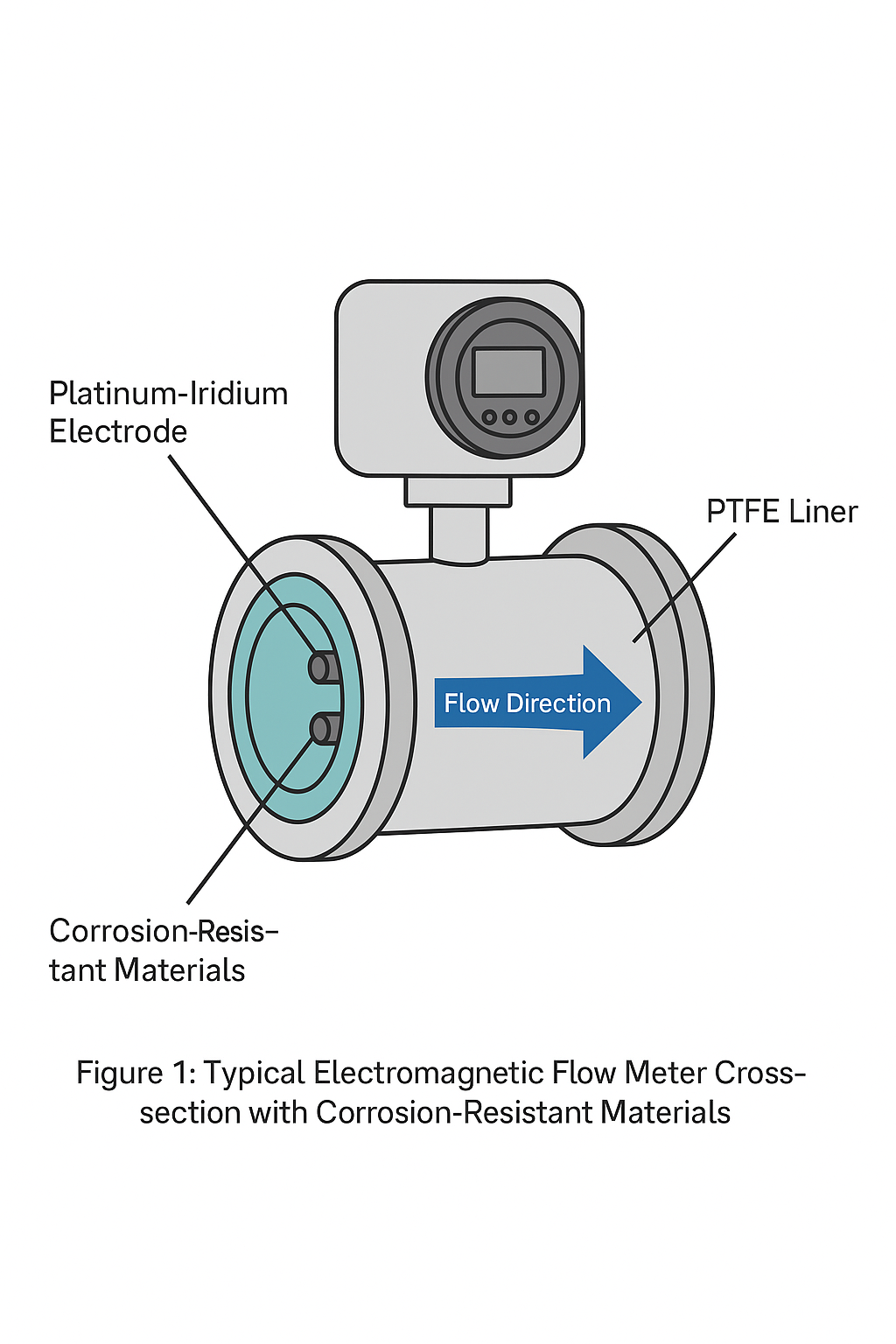

3. Anti-Corrosion Protection

Why it matters:

In corrosive environments—such as those involving acids, alkalis, salt mists, or aggressive gases—exposed instrument components may suffer from material degradation.

Recommended action:

Use flowmeters with corrosion-resistant linings and electrodes (e.g., PTFE, PFA, Hastelloy-C).

Apply protective coatings or install the instrument in sealed enclosures or protective boxes.

Schedule more frequent inspections in chemical or coastal plants.

4. Flowmeter Calibration and Re-certification

Why it matters:

Accuracy may drift over time due to wear, coating, temperature variation, or aging of components. Regular recalibration helps ensure measurement reliability.

Recommended action:

Recalibrate the flowmeter every 1 to 3 years, or after each equipment overhaul cycle, depending on the operating condition and internal quality system requirements.

Use certified calibration facilities and maintain traceable calibration records.

Summary Table

| Maintenance Task | Frequency Recommendation | Key Benefit |

|---|---|---|

| Electrode & liner cleaning | Every 6–12 months | Prevents signal drift/shorts |

| Instrument exterior cleaning | Monthly or as needed | Keeps display readable & clean |

| Anti-corrosion check | Every 3–6 months in corrosive settings | Extends equipment service life |

| Calibration / verification | Every 1–3 years | Ensures measurement accuracy |

By implementing the above maintenance measures, you can significantly extend the service life of your electromagnetic flowmeter and ensure stable, reliable measurements throughout its operation lifecycle.

If you need calibration services, spare parts, or remote diagnostics for your Zero Instrument electromagnetic flowmeter, feel free to contact us anytime.