Flow rate refers to the amount of fluid passing a certain cross-sectional area every minute unit. If you express this quantity by the fluid volume, it’s referred to as instantaneous mass flow or volume flow.

Instantaneous mass flow is when it is expressed by mass, known as mass flow. Flow measurement is a collective word for when you measure fluid flows in different specific channels.

There is diversification of the flow of fluids. The objects of measurement, for instance, are liquids, gases, and mixed fluids.

The accuracy required for pressure, temperature, and rate of flow of fluids are all different. Measurement flow aims to uncover measurement methods suited for unique measurement purposes, fluid type, flow state, and location to ensure the precise flow rate transmission value.

Flow measurement methods have been applied before in ancient times. The Egyptians predicted the growth of the year from the flow of the Nile.

Ancient Romans would measure water flow by building canals and adding more draining holes to increase accuracy.

The famous Dujiangyan Water Conservancy Project applies the water level observation technique by observing the Aquarius mouth.

Industrial procedures and agricultural processes identify the flow rate as an equally important measurement parameter besides temperature and pressure. Now, whether it is for metering or control purposes, people’s daily production lives are full of flow measurement.

This includes domestic water, gas, chemical industry, extraction and transportation of gas and oil, and industrial production. The flow rate can be termed as a dynamic quantity.

Objects to measure flow rate come in three different fluid kinds with unique physical properties; liquid, gas, and mixed multiphase fluids. Either way, various factors should be considered when measuring, and they include measurement and corrosiveness, temperature, pressure, and the flow rate. Also, the fluid state matters, and it is laminar or turbulent flow.

Liquids differ in conductivity and viscosity. You must study different fluids and how they flow for you to get precise flow measurement results. Different methods of measurement and instruments have been produced to ensure measurement procedures bear precise results.

Flow meters developed rapidly after the Second World War due to rapid international development in economy and technology.

Flow rate measurement has also increasingly gained attention over the past few years. In the N-50s, for instance, three types of flowmeters were used: Pilot tube, orifice tube, and float flowmeter.

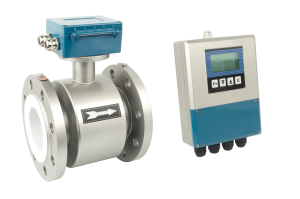

The range may be narrow, but accuracy levels have started advancing. In the last 50 years, to meet flow measurements in different conditions and fluid characteristics, meters have been developed to use velocity meters, volumetric, momentum, ultrasonic, and electromagnetic flowmeters.

Dozens of other meters with unique principles of measurement have been developed.

Today, flow measurement is applied in industrial, agricultural national defense construction, scientific research, daily life, and foreign trade.

Since industrialization has developed productively towards automation and people’s daily needs, flow meters are applied in the entire process.

Flowmeter usage is increasing daily, and it accounts for 15-30 % of the total meter numbers. Flowmeter equipment affects the operation and accounting for costs directly in enterprises.

There are 100 types of flow meters and more being used today, both abroad and at home.

There is no meter you can apply to all flow measurements. Different occasions call for different meters, which creates a large variety.

Higher and newer flow meter requirements have been staged due to the complex flow conditions for measurement and the rapidly advancing technology in science.

The measurements cannot meet life and production needs, and there are still problems that need further research.

Major problems include variety, accuracy, reliability, and specifications, which not all meters can meet.

Fluids that are corrosive, dirty, highly viscous, multiphase, small, and large flow rates pose challenges to the meters.

There is also a lack of on-site inspection, making it hard to verify flow meter requirements.

People use technologically improved achievements of the day to develop newer flow meter types and introduce technologies like laser, electromagnetic, ultrasound, nuclear technology, and microcomputers in flow measurement.

With the immense growth in technology, flow sensors have tended to be digital, electronic, multifunctional, thus opening new avenues for measurements.

The latest flowmeters have wide-scale characteristics, including the measurement ratio, high reliability, intelligence, convenient maintenance, and low prices.