In an industrial setting, a common issue arises when a process tank is equipped only with a magnetic float level switch (magnetic float type) without a remote transmission feature, making it impossible for the central control system to monitor the level. In such cases, instrumentation solutions must be explored to provide remote level transmission. This is a typical and common issue in industrial level measurement.

The magnetic float level switch itself displays the level locally, but the “remote transmission” function is achieved by converting the position signal of the magnetic float into an electrical signal.

The reed switch and magnetostrictive technologies are the two most mature and widely used solutions for remote transmission. In this article, I will compare and analyze these two technologies in terms of principles, advantages, disadvantages, and suitable application scenarios to help you make an informed decision.

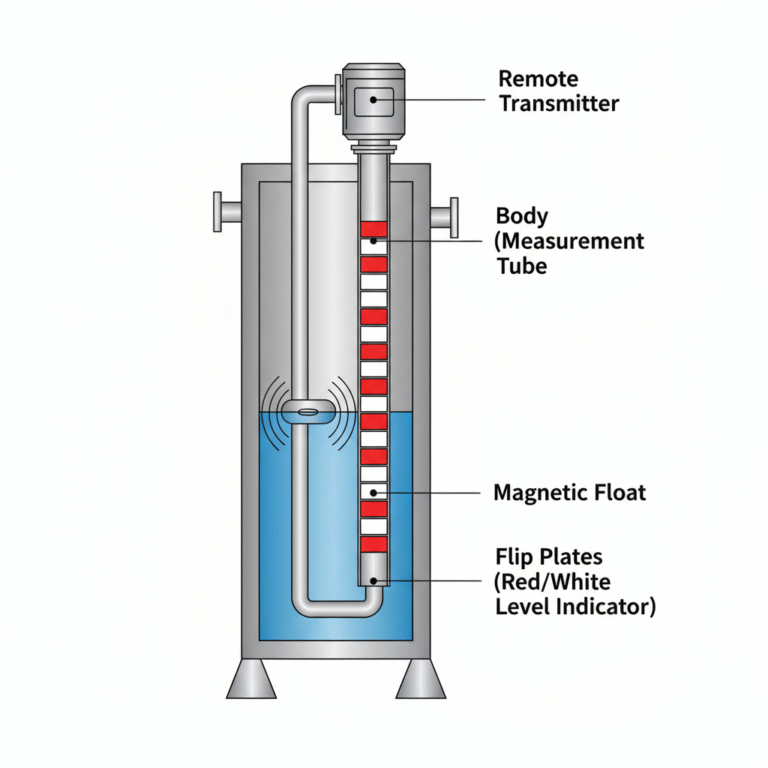

Basic Structure of a Magnetic Float Level Switch

First, let’s understand the basic structure of a magnetic float level switch:

Body: A measurement tube connected to the container, inside which there is a magnetic float.

Magnetic Float: Moves up and down as the liquid level changes.

Flip Plates: Under the influence of the magnetic field of the float, these plates flip between red and white, indicating the liquid level locally.

Remote Transmitter: An external device used to detect the position of the magnetic float and output a signal.

Solution 1: Reed Switch Remote Transmitter

This is the most traditional and widely used solution.

Working Principle

Inside the transmitter, a series of sealed reed switches (magnetic-controlled switches) and precision resistors are installed along the length of the measurement tube. As the magnetic float moves with the liquid level, its magnetic field causes the reed switches to close, altering the resistance value. The transmitter circuit detects this change and converts it into a 4-20mA analog signal or a digital signal proportional to the liquid level.

In simple terms: It functions like a “multi-position switch” controlled by a magnet, where the position of the float is determined by the resistance value.

Advantages

Cost-effective: With mature technology and simple structure, it is one of the most affordable solutions.

Simple Structure: The circuit is straightforward, easy to understand and maintain.

Versatility: It can meet the requirements of most standard operating conditions.

Disadvantages

Low Resolution, Blind Zones: Since the reed switches are spaced equally, the measurement is stepwise and discontinuous. For example, with a 10mm gap between reed switches, position changes within this range cannot be detected.

Limited Lifespan: Reed switches are mechanical contacts, and frequent switching under fluctuating or vibrating conditions can reduce their lifespan.

Susceptible to Shock and Vibration: Mechanical shock or vibration may cause reed switches to malfunction or fail.

Cumulative Error: Faults in a single reed switch or resistance deviation can lead to measurement errors across the entire range.

Solution 2: Magnetostrictive Remote Transmitter

This is a more advanced solution offering higher accuracy.

Working Principle

The transmitter consists of three main components:

Waveguide Tube: A thin metal wire closely attached to the measurement tube.

Magnetic Ring: A strong permanent magnet attached to the float.

Electronics Head: Contains the pulse generator and detection circuit.

The electronics head applies a current pulse along the waveguide tube. The pulse travels down the tube and generates a magnetic field. When this field interacts with the magnetic ring on the float, it generates an instantaneous torque (Weidmann effect), creating a torsional stress wave (return signal) in the waveguide tube. This stress wave travels back to the electronics head. By measuring the time difference between the pulse and the return signal, the absolute position of the float (liquid level) is precisely calculated.

In simple terms: It functions like “sonar” ranging, calculating the time it takes for an acoustic wave to return.

Advantages

High Accuracy and Resolution: Measurements are continuous with accuracy typically within ±1mm, and resolutions can reach 0.1mm. No blind zones.

Absolute Position Measurement: Each measurement is an absolute position, no need for cumulative calculations, and no recalibration after power loss.

Non-contact Measurement, Long Lifespan: There are no moving mechanical parts between the waveguide tube and magnetic ring, offering a virtually infinite lifespan and high reliability.

Vibration and Shock Resistant: Since there are no fragile mechanical components, this solution is ideal for environments with high vibrations.

Simultaneous Measurement of Level and Interface: Special models can measure the interface between two liquids of different densities (e.g., oil-water interface).

Disadvantages

Higher Cost: Due to the advanced technology, material, and manufacturing process, it is significantly more expensive than reed switch transmitters.

Sensitive to Magnetic Field Interference: If there are strong magnetic fields nearby (e.g., from large motors or transformers), measurement may be disrupted.

Complex Electronics: While reliable, repair costs may be higher if the electronics head is damaged.

Comparison Summary Table

| Feature | Reed Switch | Magnetostrictive |

|---|---|---|

| Measurement Principle | Magnetic switch, resistive divider | Magnetostrictive effect, time-difference measurement |

| Accuracy/Resolution | Low (cm level, ±5mm or ±10mm) | High (mm level, ±1mm) |

| Output Signal | Stepwise, discontinuous | Continuous, absolute position |

| Lifespan & Reliability | Limited by mechanical contact | Non-contact, long lifespan, high reliability |

| Vibration Resistance | Poor | Excellent |

| Cost | Low, economical | High, investment-type |

| Typical Applications | General level monitoring, process control, less precise scenarios | Precision control, metering, high reliability needs (e.g., tank gauging, interface measurement, vibrating environments) |

Selection Guidelines

Choose Reed Switch when:

Budget is limited and precision requirements are not high.

Used for general process monitoring, not for trade custody or precise metering.

The liquid level is relatively stable, without significant fluctuations or vibration.

Applications include water treatment, regular chemical storage tanks, etc.

Choose Magnetostrictive when:

High accuracy and resolution are required, such as in inventory management, trade handover, or formula control.

The equipment is installed in high-vibration environments (e.g., near pumps or moving equipment).

The liquid level fluctuates frequently and requires continuous, real-time feedback.

Interface measurement is needed (e.g., oil-water separators).

Long-term stability and low maintenance are desired, even at a higher initial cost.

Conclusion

Reed switches are the “cost-effective” option for applications that require approximate measurements, while magnetostrictive sensors are the “precise and reliable” choice for applications that demand accuracy and long-term dependability.

Make your choice based on your specific process requirements, accuracy needs, budget, and site conditions.