In industries such as petrochemicals, water treatment, energy, pharmaceuticals, and food processing, magnetic float level indicators have become the mainstream equipment for level measurement, owing to their stable performance based on magnetic coupling, convenient visual display, and simple structure with low maintenance costs. However, in practice, many procurement and operations personnel often fall into the trap of “focusing on price over compatibility” and “selecting based on experience,” ignoring critical details like medium characteristics, operational parameters, and compliance standards. This can lead to issues like corrosion, leakage, measurement drift, and significantly shortened lifespan. With years of experience in industrial instrumentation, Anhui Chuchen Technology helps companies accurately match their operational requirements with our selection guide based on GB/T 26460-2011, “Functional Safety of Industrial Process Measurement and Control Instruments,” and the “Petrochemical Automation Instrumentation Selection and Design Guidelines.” We break down the “Medium-Condition-Function” core selection logic, incorporating case studies and compliance points to ensure optimized, stable, and cost-effective operations.

1. Core Selection Criteria: Defining 3 Key Dimensions for Compliance

The essence of selecting a magnetic float level indicator lies in achieving a three-way compatibility between “equipment, operating conditions, and compliance,” where the core parameters are “Medium, Operating Conditions, and Function.” Any misalignment in any of these dimensions can lead to a chain reaction of issues. It’s crucial to first identify all dimensional parameters, then choose the appropriate solution based on industry standards, rather than making hasty purchases that may result in high future operation and maintenance costs.

Medium Characteristics Dimension

This is the primary factor in deciding the equipment’s material and structural design. It directly affects the equipment’s corrosion resistance, safety, and compliance. Industrial mediums are diverse and need to be analyzed based on five factors: corrosiveness, viscosity, crystallization, hygiene level, and flammability/explosiveness.

For highly corrosive mediums like hydrochloric acid, caustic soda solutions, and concentrated nitric acid, strict compliance with HG/T 20507-2019 “Technical Requirements for Corrosion-Resistant Materials in Steel Chemical Containers” is necessary. We recommend using custom magnetic float level indicators with 316L stainless steel and PTFE (Polytetrafluoroethylene) coatings for the float and measurement tube. This integrated anti-corrosion design helps prevent issues such as float perforation, measurement tube damage, and medium leakage.

For mediums like molten urea, caustic soda, and asphalt, which are prone to crystallization and high viscosity, we provide custom heating solutions such as steam or electrical heating, integrated with intelligent temperature control systems, ensuring the medium’s temperature stays 5-10°C above its crystallization point, preventing blockage of the float’s passage.

For hygienic scenarios such as pharmaceutical liquid storage tanks or food-grade juice tanks, we recommend using polished 316L stainless steel with Ra≤0.8μm finish. The design should avoid dead angles where residue can accumulate, and the seals should be made from food-grade materials like silicone or PTFE to prevent contamination while meeting CIP (Clean-in-Place) and SIP (Sterilization-in-Place) requirements.

Operating Conditions Dimension

Temperature and pressure are the key indicators that determine the material selection, seal performance, and structural strength of magnetic float level indicators. These parameters must strictly conform to the operational range to avoid downgraded compatibility.

Normal temperature and pressure conditions (≤80°C, ≤1.6MPa): For applications like water plants and lubricating oil tanks, carbon steel models are sufficient due to their low cost and high strength.

Medium temperature and pressure conditions (80-200°C, 1.6-10MPa): For applications like chemical reaction vessels and diesel storage tanks, we recommend 316L stainless steel with graphite seals to resist medium penetration and thermal expansion.

High-temperature conditions (≥200°C): For scenarios such as refinery catalytic cracking units and molten salt tanks, high-temperature alloys like Hastelloy C276 and Monel are ideal, as they can withstand temperatures up to 450°C.

High-pressure conditions (≥10MPa): For applications like high-pressure gas cylinders or reactors, equipment should be ASME B31.12 certified, ensuring enhanced strength and reliability.

Additional factors like vibration, dust, and outdoor exposure should also be considered, and we offer optional accessories such as vibration dampers and weatherproof covers to extend equipment lifespan and reduce maintenance costs.

Functional Requirements Dimension

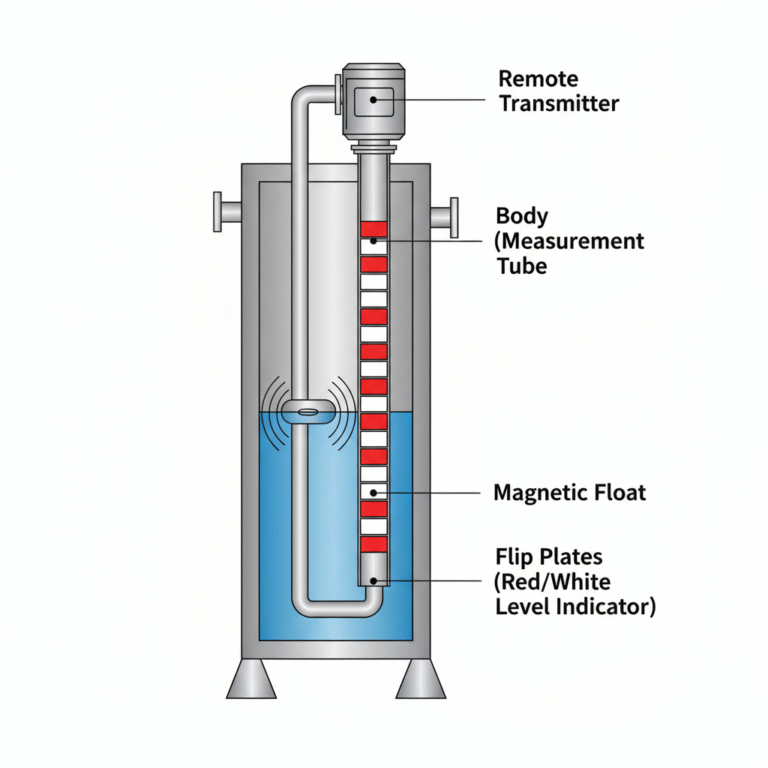

Functional compatibility should be evaluated based on operational and management needs, avoiding both functional redundancy and inadequacy. If only on-site personnel need to monitor the level, a basic magnetic float level indicator will suffice. For systems that require centralized monitoring, our smart models support remote transmission modules, with HART or 4-20mA communication protocols for stable and interference-resistant data transmission.

In case of high safety needs, optional level alarm devices can be added to set high and low liquid level thresholds, providing early warning through sound, light, or SMS notifications.

2. 4 Typical Industry Application Cases (Including Anhui Chuchen’s Practical Examples)

Chemical Industry – Corrosive Medium Conditions: A major chemical enterprise needed to measure the level in a 50m³ hydrochloric acid tank at 50°C and 0.8MPa. After an initial attempt with 304 stainless steel, the float corroded within a month. After optimization with 316L stainless steel and PTFE coating, the equipment has operated stably for 2 years, with 60% reduced operation costs compared to the previous setup.

Refinery High Temperature and Pressure Conditions: A refinery needed a level measurement solution for catalytic cracking at 280°C and 6MPa. After replacing the original 316L model with a custom Hastelloy C276 unit, the equipment has performed reliably for over 18 months.

Water Treatment Clean Conditions: For a city’s water treatment plant, a basic carbon steel model was selected for its cost-effectiveness and ease of maintenance, with no failures after 3 years of operation.

Pharmaceutical Industry Hygienic Conditions: A pharmaceutical company required GMP-compliant level measurement for their liquid storage tanks. We provided a custom polished 316L solution that passed FDA and domestic GMP inspections, ensuring hygienic compliance.

3. Common Selection Pitfalls – 5 Key Mistakes to Avoid

Mistake 1: Focusing on price over material compatibility: Always prioritize material and operational compatibility, and request material testing reports to avoid poor-quality equipment.

Mistake 2: Ignoring vibration effects: Assess vibration intensity at the installation site to prevent measurement deviations. Vibration-resistant models can be provided.

Mistake 3: Overestimating the need for remote transmission functions: Tailor the functionality to the actual operational needs to avoid unnecessary costs.

Mistake 4: Failing to plan installation space: Ensure proper planning for installation and maintenance space to make future servicing easier.

Mistake 5: Overlooking explosion-proof ratings in hazardous environments: Always verify the explosion-proof rating for flammable or explosive media.

When selecting, always check the medium characteristics, temperature/pressure range, and functional needs. Seek professional support for simulation tests, on-site surveys, and custom solutions.