Introduction

Both load cells and pressure sensors are used to measure force—but they’re not interchangeable.

Whether you’re building an industrial weighing system, a fluid monitoring setup, or a materials testing platform, choosing the wrong type of sensor can lead to inaccurate data, system failure, or costly redesigns.

This article compares load cells and pressure sensors, explains how each works, and helps you decide which one best fits your application.

1. Basic Definitions

🟦 What Is a Load Cell?

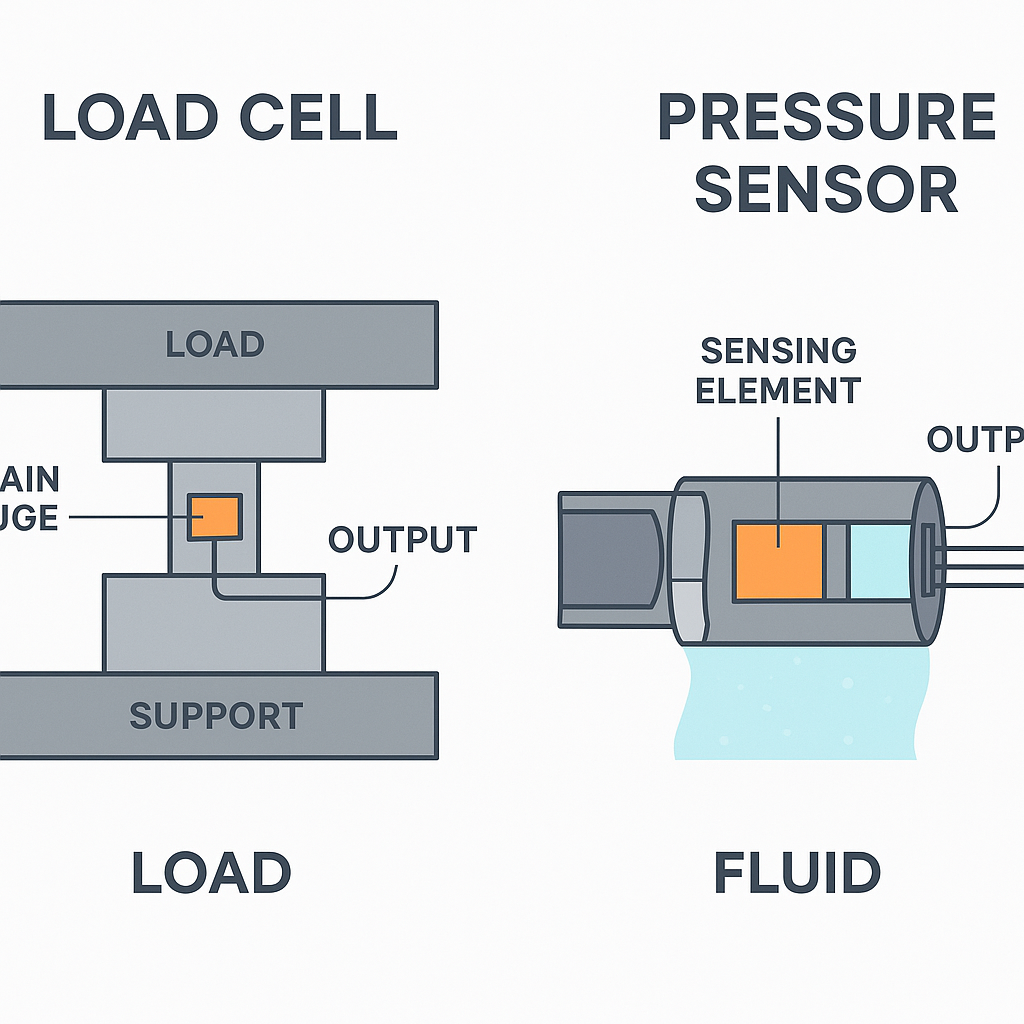

A load cell is a sensor that measures force applied to a solid object, typically in tension or compression. It converts that force into an electrical signal, often using strain gauge technology.

Measures: Direct mechanical force (linear)

Units: Newtons (N), kilograms (kg), pounds (lbf)

🟥 What Is a Pressure Sensor?

A pressure sensor measures force applied over an area, usually by fluids (gases or liquids). It converts pressure into a proportional electrical signal.

Measures: Fluid pressure (force/area)

Units: Pascal (Pa), bar, psi

2. Measurement Focus

| Feature | Load Cell | Pressure Sensor |

|---|---|---|

| What It Measures | Linear force or weight | Fluid or gas pressure |

| Measurement Interface | Solid contact surface | Pressure port (sealed or vented) |

| Output Type | mV/V, 4–20 mA, RS485, CAN | Same (depends on model) |

| Mounting | Mounted between structure & load | Screwed into fluid system or pipe |

3. Applications: When to Use Which?

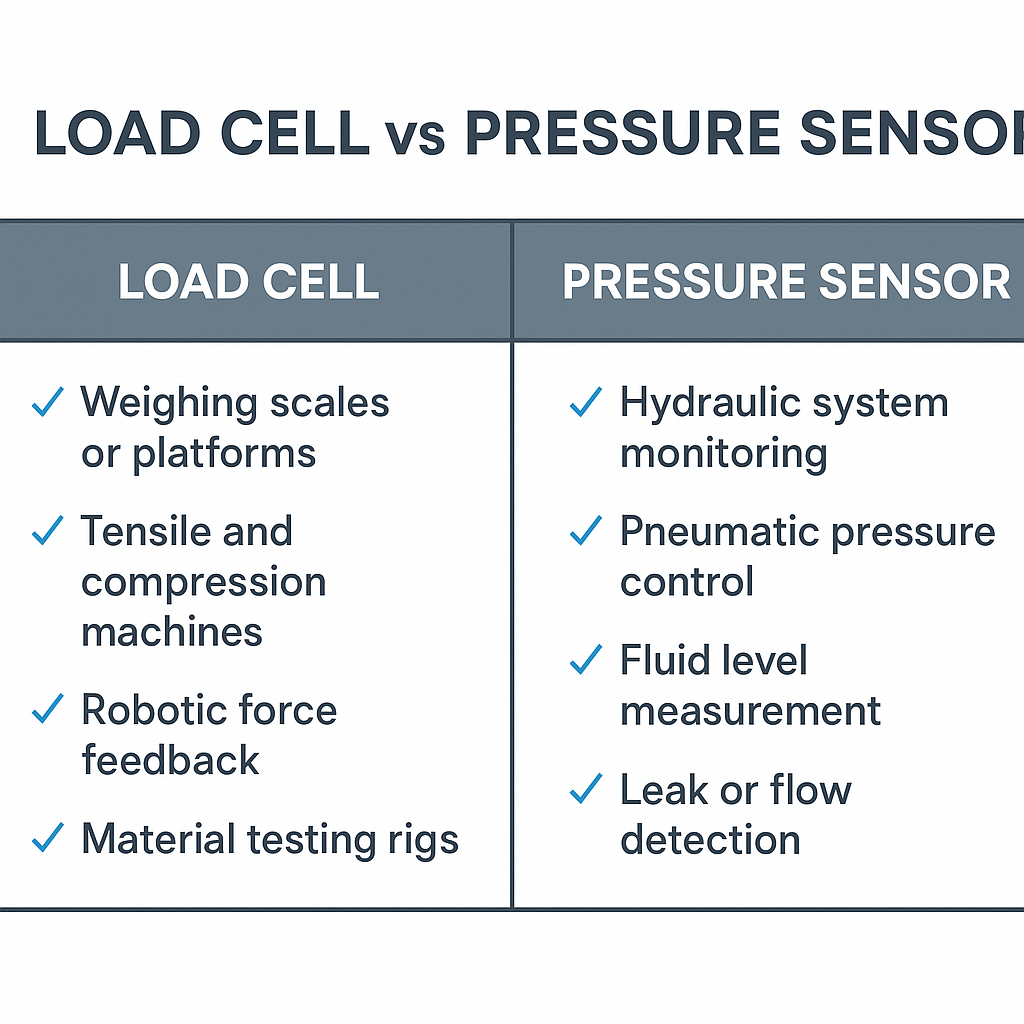

✅ Use a Load Cell When:

You’re measuring weight or direct mechanical force

The load is solid, not fluid

You’re building a weighing scale, tension control system, or material testing rig

Precision linear force feedback is needed (e.g., in robotics or mechanical presses)

✅ Use a Pressure Sensor When:

You need to measure fluid or gas pressure

You’re monitoring hydraulic or pneumatic systems

Your goal is to infer force indirectly through pressure

The environment is sealed, pressurized, or vacuumed

4. Key Differences at a Glance

| Comparison Area | Load Cell | Pressure Sensor |

|---|---|---|

| Target Medium | Solid objects | Fluids (gases/liquids) |

| Primary Use | Weighing, tensile testing, force monitoring | Flow, pressure, level, leak detection |

| Measurement Unit | Newton (N), kg, lbf | Pa, bar, psi |

| Mounting Method | Under or between structure | Tapped into pipe or pressure chamber |

| Structural Size Range | Compact to large (for heavy loads) | Very compact to small |

| Typical Accuracy | 0.02% to 0.05% F.S. | 0.1% to 0.5% F.S. |

5. Can They Be Used Together?

Yes. In many systems—like hydraulic press machines, injection molding, or fluid weight tanks—load cells and pressure sensors are both used to:

Monitor structural load and internal fluid pressure simultaneously

Provide redundancy or cross-verification of system status

Enable combined control of force and pressure in real time

Conclusion

While both load cells and pressure sensors are force-related, they serve very different roles:

Load cells are for measuring direct mechanical force in solid structures

Pressure sensors are for monitoring fluid pressure within sealed systems

By understanding their core differences, you can choose the right sensor for your design—saving cost, simplifying integration, and improving accuracy.