A limit switch is an electromechanical device used to detect the presence or absence of an object or the position of a mechanical component. It operates by physical or non-contact interaction with a moving object, causing a change in its internal contacts, which either opens or closes the circuit. Limit switches are essential in industrial automation, as they ensure the precise control of mechanical movements and safeguard machinery by stopping operations when components reach predefined limits. This article explores the working principles, types, and various applications of limit switches.

Working Principle of Limit Switches

The working principle of a limit switch revolves around its ability to sense mechanical motion and trigger an electrical response. When an object reaches the predefined limit, the switch is actuated, causing its internal contacts to either make or break the circuit. This electrical change is used to control machinery or signal that a certain position has been reached.

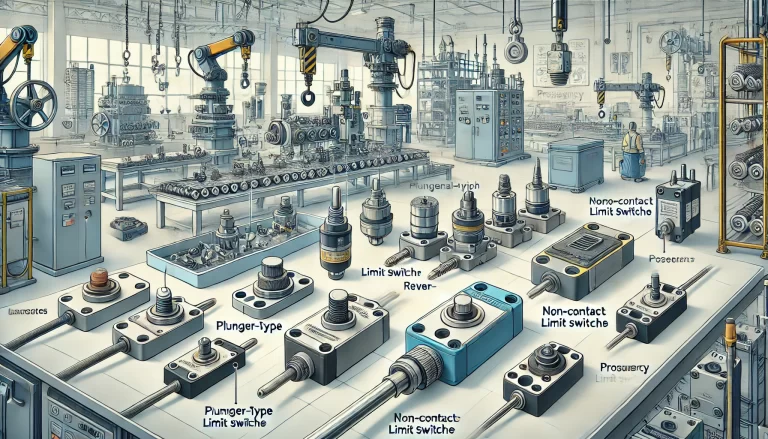

Limit switches are commonly divided into two main categories based on their operating mechanisms:

Contact Type Limit Switches: These are mechanical limit switches that require physical contact with the moving object to actuate. They are typically equipped with actuators like levers, plungers, or rollers. When the moving part comes into contact with the actuator, the force is transferred to the internal contacts of the switch, which either opens or closes the circuit. This type of switch is widely used for applications that require precision and durability.

Non-Contact Type Limit Switches: These use technologies such as magnetic, optical, or proximity sensors to detect the position of an object without physical contact. Non-contact limit switches are preferred in environments where dust, moisture, or other factors could affect the performance of a contact-based switch. They are ideal for high-precision or sensitive applications.

Key Components of a Limit Switch

A limit switch typically comprises several important components:

- Actuator: The part of the switch that comes into direct contact with the moving object. It transfers the mechanical force to the switch’s internal components.

- Contacts: Internal electrical connections that either open or close depending on the position of the actuator.

- Housing: A durable casing that protects the internal components from environmental factors like dust, moisture, and physical damage.

- Terminals: The connection points where the limit switch is wired into the control system.

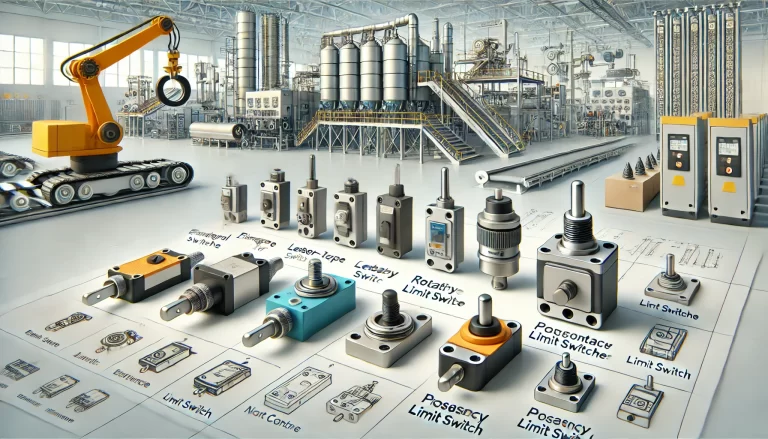

Types of Limit Switches

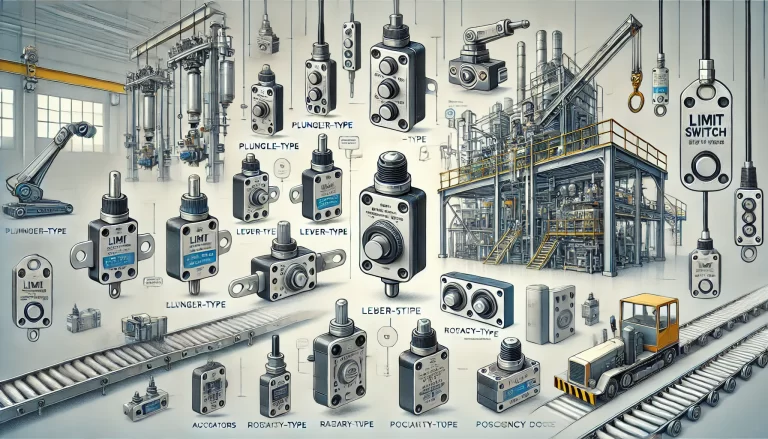

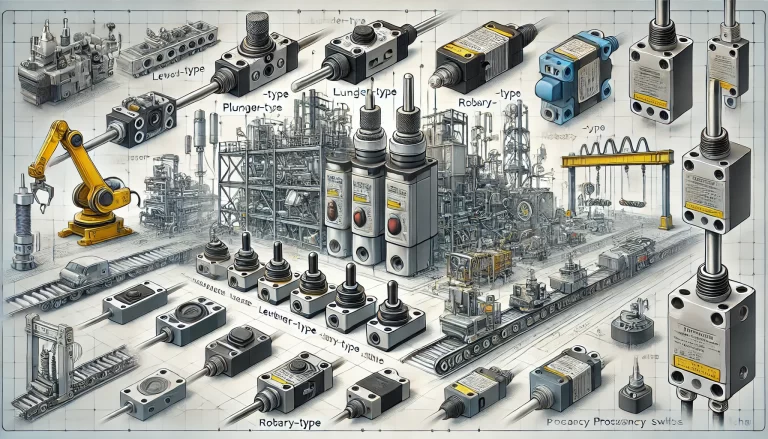

There are various types of limit switches based on their design, actuation method, and intended application. The most common types include:

Plunger-Type Limit Switch: Features a plunger actuator that is pressed when the target object makes contact. These are suitable for precise position detection.

Lever-Type Limit Switch: Contains a lever arm with a roller or ball on its end. When the moving part touches the lever, the switch is actuated. This type is commonly used in conveyor systems or automated assembly lines.

Rotary Limit Switch: Utilizes a rotating actuator that is turned by the movement of machinery parts. It is typically employed in applications where rotational motion is involved, such as cranes or hoisting devices.

Proximity Limit Switch: A non-contact switch that detects objects using electromagnetic fields or light (optical). It is widely used in environments where cleanliness or non-intrusive sensing is required.

Applications of Limit Switches

Automated Production Lines: In manufacturing, limit switches are essential for controlling automated machinery. They detect the position of mechanical components, ensuring the safe and efficient operation of processes like assembly, packaging, and material handling. For example, they can halt the movement of a conveyor belt once the desired position is reached.

Safety Mechanisms in Machines: Limit switches are often used as safety devices to prevent machinery from exceeding certain operating limits. For instance, in CNC machines, they can stop the machine if it travels too far in a given direction, preventing damage to both the machine and the workpiece.

Elevator Systems: Limit switches play a critical role in the control and safety of elevators. They detect the position of the elevator car, ensuring that it stops accurately at each floor and that doors operate correctly without collisions.

Automated Doors and Gates: Many automatic doors, gates, and barriers use limit switches to detect the open or closed position, controlling motorized systems and ensuring that the door does not overextend or remain open when it should be closed.

Smart Home Applications: Limit switches are used in various smart home devices such as automated blinds, garage doors, and home security systems. These switches can detect whether a door or window is fully opened or closed and provide signals to the control system to initiate the appropriate response.

Agricultural and Heavy Machinery: In equipment such as tractors, harvesters, and mining machinery, limit switches are often used to monitor the movement of parts like arms, blades, or lifts, ensuring safe operation in challenging environments.

Robotics: In robotics, limit switches ensure that robot arms and other components operate within safe, predefined boundaries. They can be used to limit the range of motion of a robotic arm, preventing mechanical overload or collisions.

Advantages of Limit Switches

High Reliability: Limit switches are highly reliable and capable of operating in harsh conditions. Their robust construction ensures long operational life, even in environments with extreme temperatures, dust, or moisture.

Precision: Limit switches provide precise control and repeatability, making them ideal for applications that require accurate position detection.

Cost-Effectiveness: Compared to other types of sensors, limit switches are relatively inexpensive and easy to install. This makes them a popular choice in industrial applications where cost is a significant consideration.

Wide Range of Applications: From simple home automation systems to complex industrial machinery, limit switches can be adapted to suit a variety of needs.

Conclusion

Limit switches are versatile and essential devices in both industrial automation and everyday applications. By providing accurate feedback on the position and movement of mechanical components, they help ensure the safe and efficient operation of equipment. Whether used in elevators, production lines, or smart home systems, limit switches continue to be a reliable and cost-effective solution for position detection and machine control. As technology advances, limit switches will remain a critical component in the design of modern automated systems.