Radar level transmitters are widely used across industrial applications to measure tank and vessel levels using microwave-based distance measurement.

Among all selection parameters, the dielectric constant (εr) of the medium is one of the most critical factors affecting radar performance.

🔹 1. What Is Dielectric Constant and Why It Matters

The dielectric constant, also called the relative permittivity, indicates a medium’s ability to store electric field energy.

A higher dielectric constant means stronger microwave energy reflection and more reliable level measurement.

From a process perspective, the dielectric constant of the measured medium directly influences radar performance.

Materials are generally divided into three categories:

Non-polar (εr < 2.8)

Weakly polar (2.8 ≤ εr ≤ 3.6)

Strongly polar (εr > 3.6)

🔹 2. How Dielectric Constant Affects Radar Measurement

✔ a. Echo Reflection Strength

Higher dielectric constant → stronger microwave reflection → clearer echoes → higher accuracy.

Low dielectric constant → weak reflection → unstable measurement.

Therefore, radar performs best on liquids such as water, alcohols, and glycols.

✔ b. Propagation Velocity

Microwave velocity varies with dielectric constant.

If not compensated, changes may introduce reading errors.

Accurate calibration is needed for high-accuracy applications.

✔ c. Signal Interference

If dielectric constant changes within the tank (mixing, debris, foam), the radar signal may scatter or reflect multiple times, producing false echoes.

Modern radar systems use echo filtering, suppression, and averaging to stabilize results.

🔹 3. Dielectric Constant Requirements for Different Radar Types

1) Non-contact Radar (Horn / Antenna Type)

Ideal for large tanks and standard liquids

Typical dielectric constant requirement: εr ≥ 1.8

Media below 1.8 (LPG, LNG, gasoline) produce weak reflection

May be affected by agitation, vapor, and foam

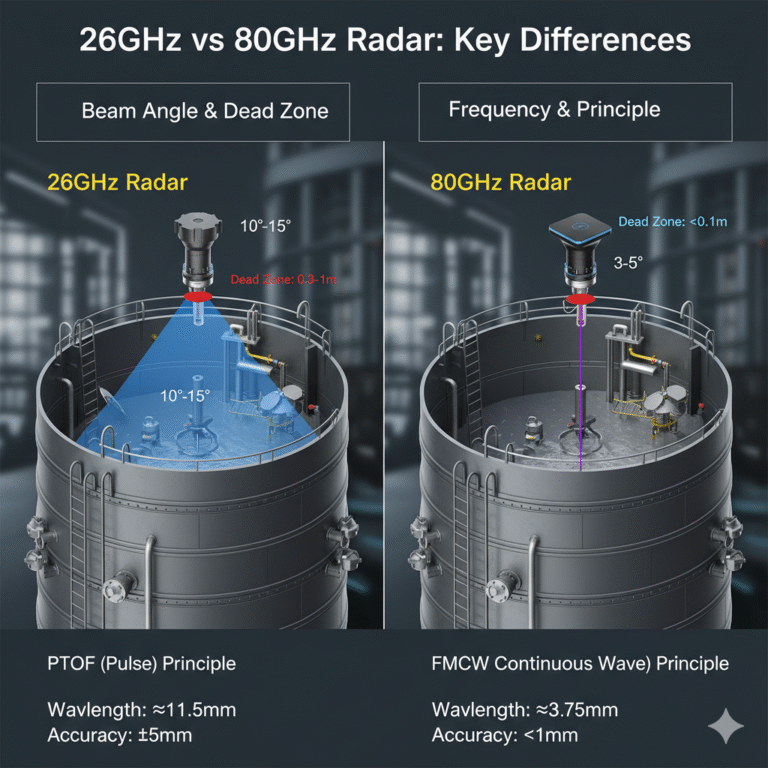

💡 Best fit: High-frequency radars (e.g., 80 GHz) improve performance on low-reflectivity media.

2) Guided-Wave Radar (Rod / Cable Type)

Suitable for small vessels, viscous media, or low εr liquids

Can measure media with εr as low as 1.4

The probe guides microwave energy directly to the liquid surface, improving echo reliability

⚠ Limitation: Media that coat or crystallize on the probe may block energy transmission.

🔹 4. Practical Selection Considerations

✔ a. Layered or Multiphase Media

When two layers exist (e.g., oil/water), radar can detect the interface only when dielectric difference is large.

Example:

Water εr ≈ 80 vs oil εr ≈ 2 → clear interface

If two media have similar εr, interface cannot be measured reliably

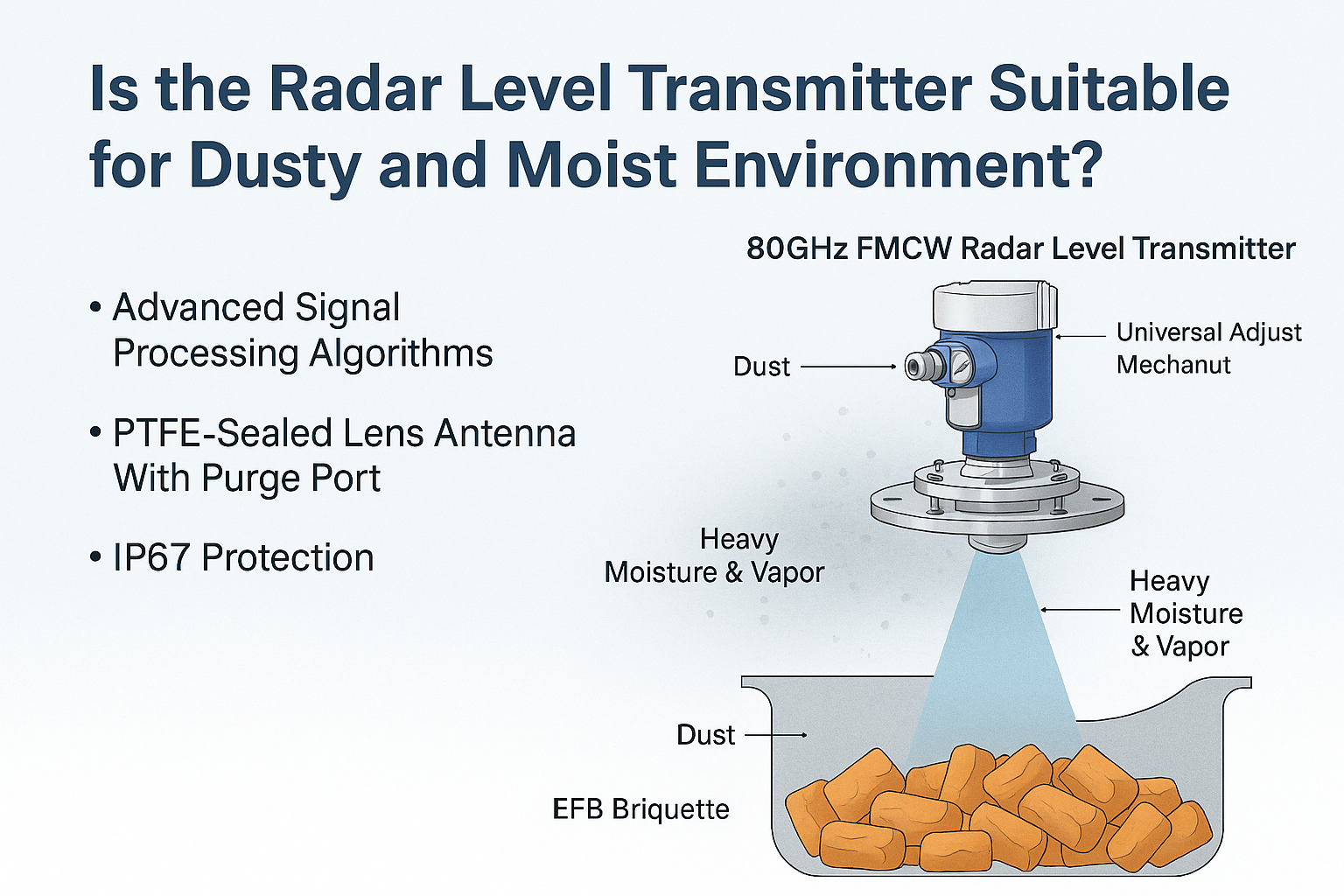

✔ b. Gas Phase Influences

High moisture vapor, steam clouds or corrosive gases may absorb or scatter radar signals.

Solutions:

Sealed antenna

Air purge

PTFE/PP antenna cover

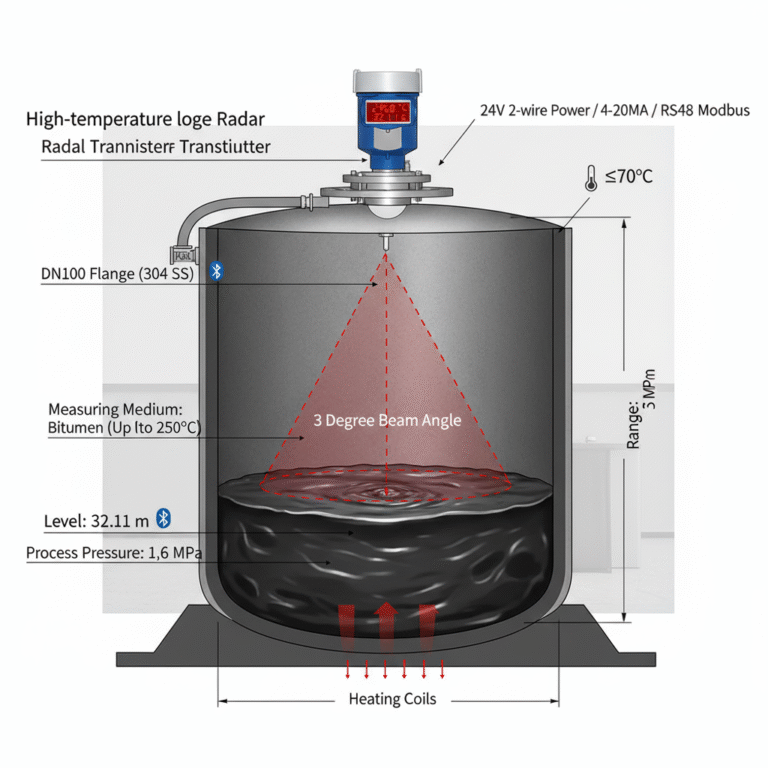

✔ c. Temperature & Pressure Effects

Dielectric constant may shift under extreme temperatures or pressure.

e.g., water εr decreases as temperature increases

➡ Always evaluate εr under operating conditions, not room temperature.

🔹 5. Engineering Selection Tips (Quick Guide)

| Application | Recommended Radar |

|---|---|

| Standard industrial liquids, εr ≥ 10 | Non-contact radar |

| Low dielectric media (LPG, gasoline, εr < 2) | Guided-wave radar or 80 GHz |

| Oil–water interface | Allowable εr difference ≥ 5 |

| Viscous or foaming liquids | Guided-wave radar (with proper probe type) |

✅ Conclusion

The dielectric constant of the medium is one of the most decisive factors influencing radar level measurement performance.

Correct selection of radar type—combined with calibration and proper installation—ensures stable operation and long-term accuracy in demanding industrial applications.