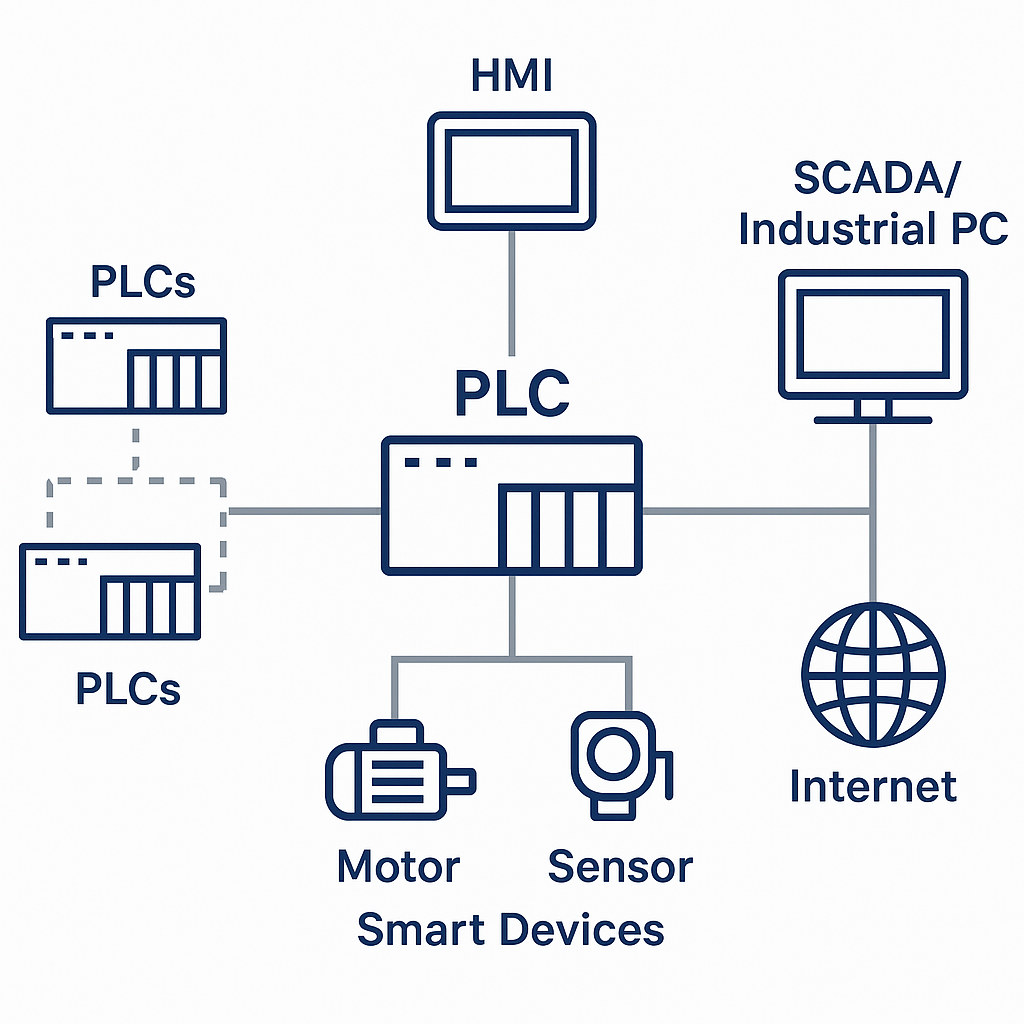

Programmable Logic Controllers (PLCs) are designed to operate reliably in industrial environments, but proper installation practices are critical to ensure long-term stability, safety, and maintainability. This document summarizes the key requirements for PLC installation, covering environmental conditions, grounding, cabinet setup, commissioning, redundancy testing, program backup, and software maintenance.

1. Environmental Requirements

Enclosure: Install PLCs in protective control cabinets with an IP rating suitable for the application.

Ambient Temperature: Maintain between 0–50 °C, with adequate space for heat dissipation.

Humidity: Relative humidity less than 85%, non-condensing.

Air Quality: Avoid corrosive, flammable gases or conductive dust.

Vibration/Shock: Installation site should have minimal vibration; avoid shocks greater than 2 g.

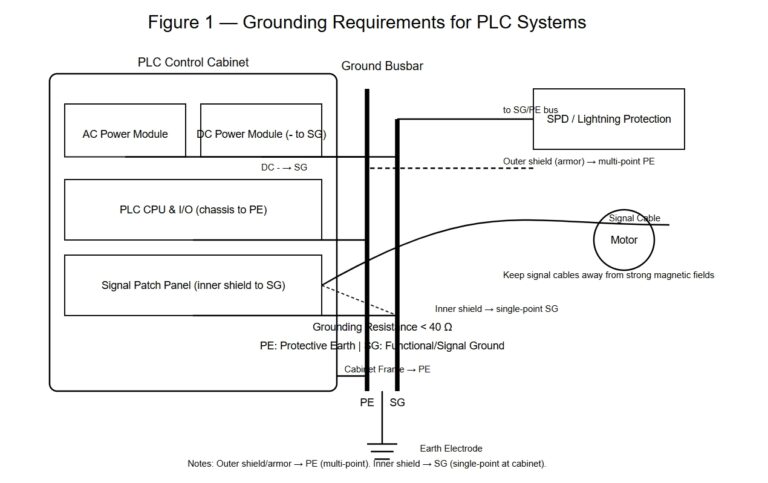

2. Grounding Requirements

Proper grounding enhances system safety and immunity to electromagnetic interference (EMI). Key points include:

PLC system grounding resistance should be less than 40 Ω.

AC supply circuits, chassis, and mounting frames must be connected to protective ground (PE).

In DC circuits, connect the negative terminal to the working ground; signal shielding layers should be single-ended grounded at the cabinet.

Cable armors should be grounded at multiple points, while inner shields are typically grounded at the working ground.

Signal wiring must be routed away from strong magnetic fields and large motors; use overall-shielded and pair-shielded cables when possible.

In lightning-prone areas, install surge protection and dedicated grounding.

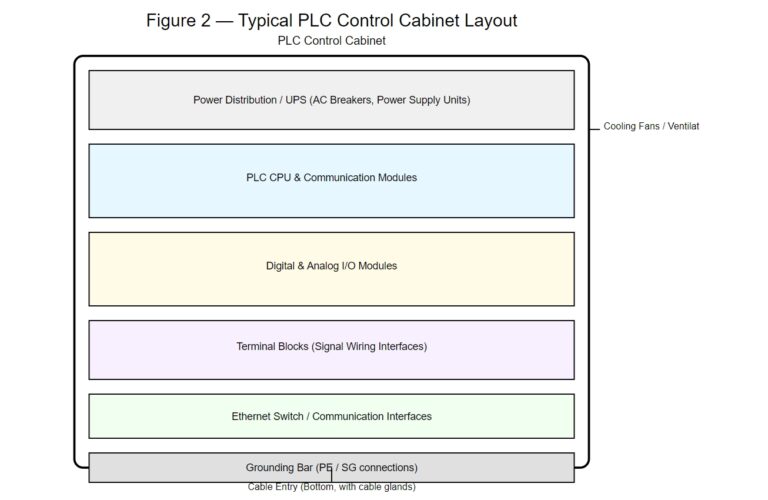

3. Control Cabinet Installation Checklist

Before placing PLC cabinets in position, ensure the following:

Cabinet foundations (steel frame, anti-corrosion treatment) are completed and meet design specifications.

Civil works such as flooring, doors, and windows are finished, with the area clean and dust-free.

Power supply (including UPS) and lighting systems are completed and operational.

Grounding electrodes and busbars are installed; grounding resistance meets design requirements.

The control room is sealed, with functional air-conditioning, fire extinguishers, and safety devices.

Both protective and working grounding systems have been inspected and meet standards.

4. Pre-Commissioning Conditions

PLC system commissioning must only begin when the following conditions are met:

Detailed commissioning plan, steps, and records are prepared.

Instrumentation and power cables are installed correctly; power supply and grounding tested.

Field instruments and actuators are installed, tested, and operational.

Electrical subsystems are ready to receive and process PLC output signals.

Basic system functional tests are complete with documented reports.

Alarm setpoints, interlock values, and PID parameters are confirmed.

Required personnel are available for coordination during testing.

5. Redundancy Power Supply Testing

For redundant PLC systems:

Disconnect one power source; the system should continue operating without disturbance.

Reconnect the power; the system should recover normally.

Repeat the test for the other power source.

Verify correct mapping between power modules and upstream switches.

6. Program Backup and Archiving

Regular backups protect against data loss due to power failure, hardware fault, or accidental modification.

Backup at least once per year or before/after program modifications.

Maintain software maintenance logs and update relevant logic diagrams and documentation.

Store backups using external media (USB drives, optical discs, external HDDs).

Avoid storing backups only on the local hard drive to prevent virus or hardware failures.

7. Software Maintenance

PLC software maintenance covers three areas:

Operating System (Windows) Maintenance

Apply security patches carefully and update antivirus databases.

Change system passwords regularly.

Configuration/Programming Software Maintenance

Ensure compatibility of software version with hardware modules and firmware.

Application Program Maintenance

Backup applications periodically.

Keep records of logic changes, parameter adjustments, and channel modifications.

Synchronize documentation after every update.

8. Summary

A well-installed PLC system provides greater reliability, stronger EMC protection, and reduced maintenance costs. Following best practices in environmental control, grounding, cabinet setup, commissioning, redundancy testing, program backup, and software maintenance ensures long-term system safety and operational stability.