The refining sector forms the first and one of the most critical segments of the petrochemical processing chain. By the end of 2016, China had reached a refining capacity of 750 million tons per annum, accounting for 15% of global capacity and ranking second in the world. Instrumentation and automation systems in refineries are designed to meet the overarching objectives of safety, stability, continuous operation, maximum throughput, and optimization.

Automation in refining demands extremely high standards of safety, reliability, and real-time responsiveness. It adheres to a comprehensive set of international, national, and industry-specific standards. Although a significant portion of automation equipment is imported, domestic instrumentation and distributed control systems (DCS) have seen increasing adoption, particularly in standard production units. However, high-temperature, high-pressure scenarios and safety instrumented systems (SIS) remain dominated by foreign suppliers.

With rapid advancements in technologies—especially computing, display, and communication—instrumentation and automation in refining have evolved with distinctive features and trends.

I. Technical Characteristics

1. Miniaturization, Modularity, and High Reliability Modern instrumentation emphasizes compact design and modular construction. With fewer moving parts, instruments have become easier to maintain and significantly more reliable. Maintenance focuses primarily on sensor interfaces and sample preprocessing systems, while instrument failure has become rare.

2. Intelligence and Self-Diagnostics Intelligent instruments integrate microprocessors, large-scale integrated circuits, and embedded software. They offer self-diagnostics, data analysis, and enable predictive maintenance planning, improving operational efficiency. Additionally, these devices can be networked for seamless integration with broader control systems.

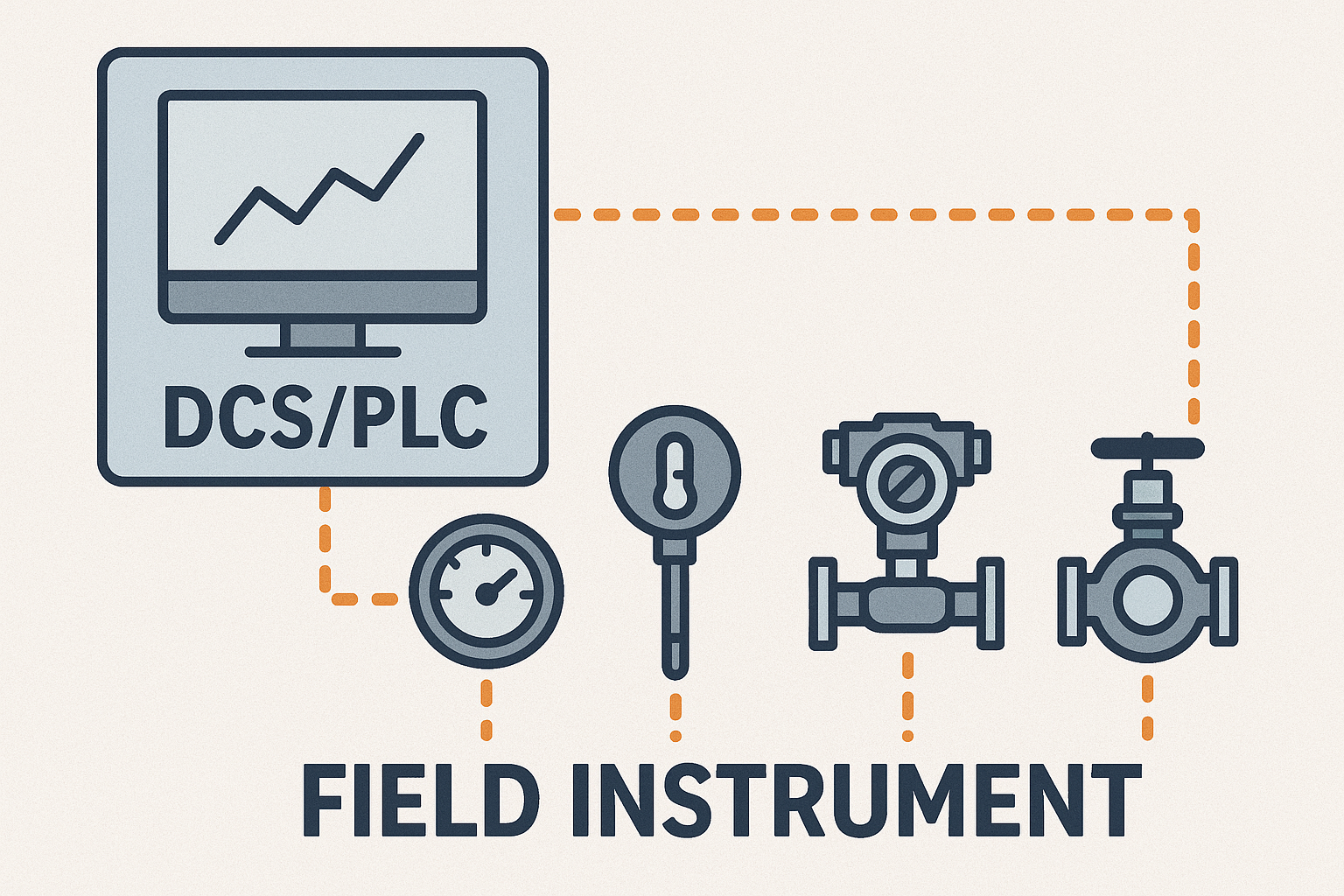

3. Digitalization, Fieldbus, and Wireless Communication Field instruments—including transmitters, analyzers, and actuators—are increasingly adopting fieldbus protocols. This shift facilitates centralized and distributed control system architecture. Digital communication forms the foundation for smart factories and Industrial IoT (IIoT). Wireless smart transmitters are gaining popularity, particularly in remote, unmanned sites.

4. Networking and System Integration With the integration of fieldbus and digital communication technologies, instrumentation systems become part of the enterprise-wide information network. This integration enhances monitoring, diagnostics, and overall system transparency.

5. Open Architecture Modern automation platforms utilize embedded operating systems like Windows CE, Linux, and VxWorks. These systems support multiple communication protocols, allow interoperability among diverse field devices, and facilitate open and scalable monitoring and control solutions. However, as systems become more open, cybersecurity risks also increase.

II. Application-Level Features

1. Increasing Reliance on Online Analytical Instruments Online analyzers provide real-time data on product and process parameters, enabling operators to respond quickly and maintain control accuracy. Their preprocessing systems remain critical to ensure reliable performance.

2. Expansion of Video Monitoring Applications Beyond traditional security roles, video surveillance is now widely used for process monitoring, such as observing furnace interiors. With advancements in image recognition, video systems are expected to penetrate inaccessible or hazardous areas.

3. Advanced and Optimized Control Strategies The application of advanced process control (APC) and optimization algorithms has become more prevalent. These technologies extend beyond the limitations of conventional PID control, offering enhanced stability and energy efficiency.

4. Environmental Compliance and Zero Emission Goals China’s enforcement of stringent environmental regulations since 2016 has pushed refineries toward zero emissions and zero leakage. All emission outlets are required to be equipped with Continuous Emission Monitoring Systems (CEMS), forcing enterprises to embrace clean production and technological upgrades.

5. Functional Safety Becomes Standard Practice SIS systems have evolved into a vital component of automation in hazardous processes. Functional safety management and system design now follow structured international frameworks, ensuring risk reduction and regulatory compliance.

6. Cybersecurity at a National Priority Level As industrial control systems increasingly interconnect with enterprise IT networks, cybersecurity risks become more significant. National policies now mandate protection grading and cybersecurity audits for critical infrastructure.

III. Management-Level Trends

1. Shift from Repair to Preventive Maintenance Due to modular design and improved reliability, traditional repair work has diminished. Modern maintenance prioritizes proactive care, ensuring pressure lines and signal paths remain unobstructed.

2. Lifecycle and Predictive Asset Management Failure-based maintenance is gradually replaced by predictive maintenance, supported by diagnostics and condition monitoring tools like thermal imaging and ultrasonic testing. Lifecycle management has gained prominence.

3. Integration of Control and Management Systems With the convergence of operational technology (OT) and information technology (IT), systems like ERP, MES, EMS, and OA are increasingly integrated. This trend supports smart manufacturing and industrial digital transformation aligned with Industry 4.0.

4. Transition to Specialized and Market-Oriented Maintenance Services Previously centralized maintenance departments are being replaced by professional service providers specializing in different instrumentation categories. This shift raises new concerns around knowledge transfer and system security.

5. Centralized Instrumentation Management Many refineries have consolidated instrumentation oversight into centralized units, replacing the traditional two-tier management system. This enhances efficiency and ensures consistent technical standards.

6. Multidisciplinary Talent Development Instrumentation professionals now require knowledge in areas like process engineering, electromechanics, IT, and communications. Cross-disciplinary expertise is crucial for developing and maintaining modern automation solutions.