1. Overview

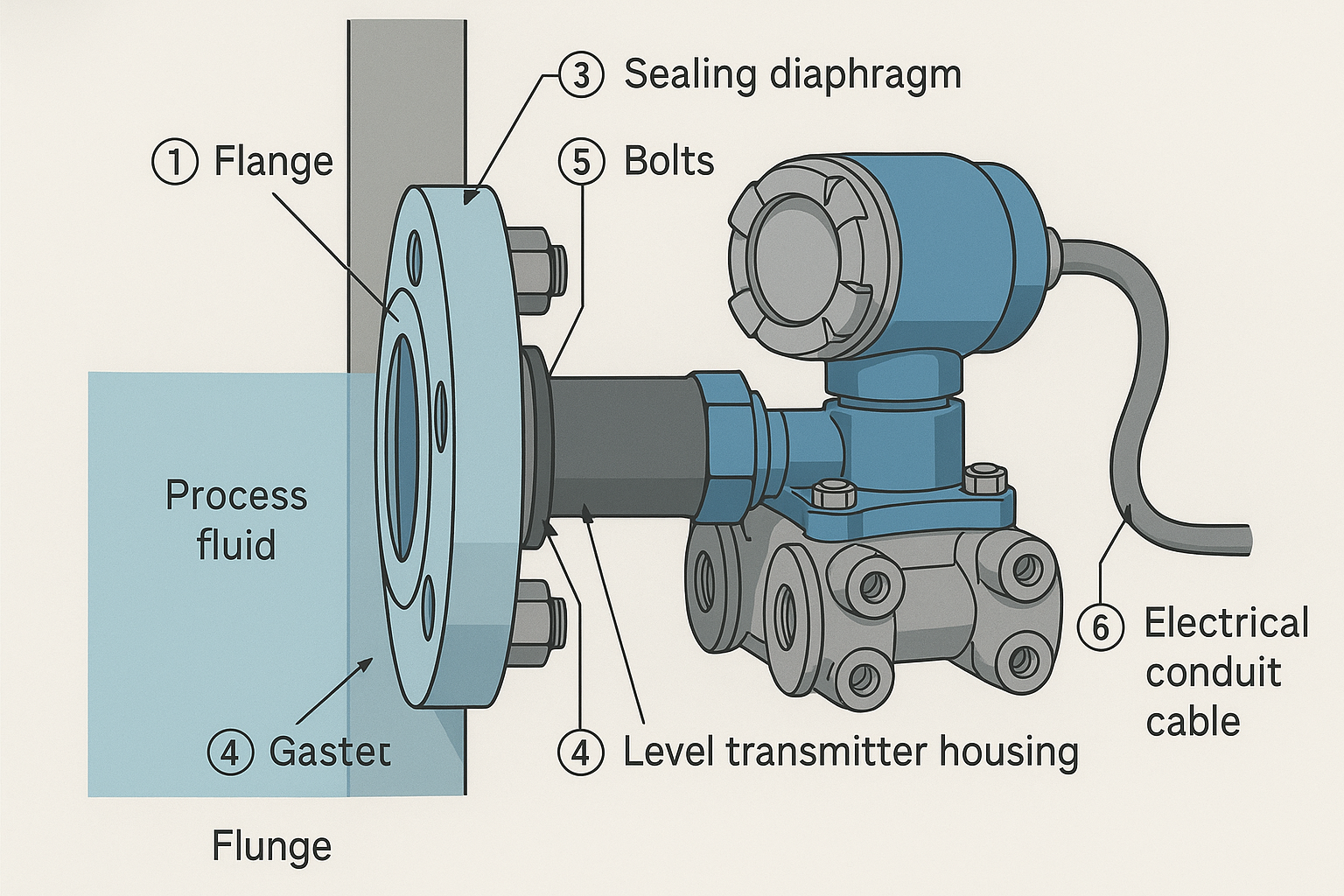

Flange-type level transmitters are widely used in industrial processes for continuous level measurement in various storage tanks, vessels, and reaction containers. These instruments are commonly applied in sectors such as metallurgy, chemical processing, environmental protection, electric power, pulp and paper, pharmaceuticals, textiles, food and beverage, and municipal engineering. Their popularity is closely related to their outstanding technical features, which ensure reliable performance under diverse conditions.

This document outlines the five key features that distinguish flange-mounted level transmitters from other types.

2. Main Features

2.1 Flexible Zero and Span Adjustment

The zero point and measurement span can be easily adjusted within the effective measuring range. This enables users to perform zero suppression or range shifts to meet specific application requirements, without removing the transmitter from the process.

2.2 High Measurement Accuracy

Flange-type level transmitters typically offer high precision, with accuracy levels reaching up to ±0.1% of Full Scale (FS). This makes them suitable for applications requiring precise level control, such as dosing systems and critical storage monitoring.

2.3 Excellent Vibration Resistance

The transmitter is designed using solid-state components and plug-in electronic modules. It maintains stable output even under mechanical vibrations. In laboratory tests, vibration at 200 Hz results in a maximum output deviation of only ±0.2% of URL per g of acceleration, making it suitable for environments with rotating machinery or mechanical disturbances.

2.4 Superior Corrosion Resistance

All wetted parts, including the diaphragm, process flange, vent valve, and fittings, are constructed from 316L stainless steel. This provides excellent resistance to corrosive media, such as acids, alkalis, and salts, commonly found in chemical and petrochemical industries.

2.5 Explosion-Proof Design

Flange-type level transmitters are available with explosion-proof or intrinsically safe enclosures, compliant with international standards (e.g., Ex ia IIC T6 Ga or Ex d IIC T4 Gb). This allows safe deployment in hazardous areas such as oil refineries, gas plants, and chemical processing zones.

3. Typical Applications

Underground or elevated storage tanks for water, oil, or chemicals

Acid or alkali dosing tanks in chemical plants

Boiler feedwater level monitoring in power stations

Sewage or sludge level measurement in wastewater treatment facilities

CIP (Clean-in-Place) tanks in food and beverage factories

4. Conclusion

With their robust structure, precise measurement, corrosion resistance, and explosion-proof capability, flange-type level transmitters offer reliable and flexible solutions for demanding level measurement tasks across a wide range of industrial environments.