1. Introduction

Plant start-up and shutdown are routine operations in chemical plants. While short-term shutdowns have limited impact on instrumentation, extended shutdowns—such as those required for major overhauls or unexpected events—demand careful attention from instrumentation engineers and technicians. Improper handling can lead to equipment damage, delayed commissioning, or even safety incidents.

This document provides technical guidance and safety precautions for instrumentation personnel during plant start-up and shutdown. Commissioning of new plants is excluded from this scope.

2. Instrumentation During Plant Shutdown

2.1 Coordination and Planning

Work closely with process operators to understand shutdown schedules and equipment maintenance plans.

Ensure proper documentation and alignment with maintenance teams before dismantling any instrumentation.

2.2 Instrument Dismantling Precautions

Power and Utility Isolation – Always disconnect instrument power supply or air supply before dismantling.

Level and Pressure Instruments – Confirm tanks are emptied before removing flange-mounted differential pressure transmitters or level gauges. If draining is difficult, ensure the liquid level is below the instrument tapping point and install blind flanges immediately after removal.

Thermocouples and RTDs – Label and insulate cable ends properly after removal to avoid damage and confusion during reinstallation.

Pressure Instruments – Loosen bolts gradually to release trapped pressure and prevent sudden release of residual fluids or gases.

Pneumatic Instruments – Shut off air supply, depressurize filter–regulator units, and safely disconnect.

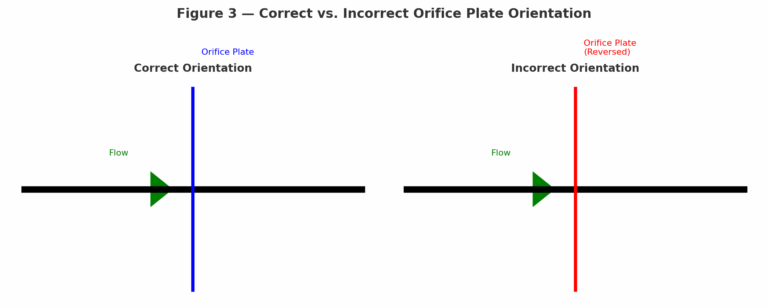

Orifice Plates and Restriction Devices – Note the flow direction during removal to avoid incorrect reinstallation. Support the pipeline to prevent sagging when removing orifice assemblies.

Tagging – Clearly mark each instrument tag number to ensure correct reinstallation and prevent range mismatches.

Interlocked Instruments – Switch to manual mode before disconnection.

3. Instrumentation During Plant Start-up

3.1 General Considerations

Start-up success strongly reflects the quality of instrument maintenance and preparation. Instrument-related failures are among the most disruptive causes of start-up delays.

Instrument teams must synchronize their actions with process operators to avoid schedule impacts.

3.2 Key Start-up Tasks

Instrument Installation – Reinstall dismantled instruments in correct tagged positions under operator supervision.

Power Supply Verification – After wiring and connections are checked, energize instruments carefully. Verify 24 VDC supply levels to avoid over/under voltage.

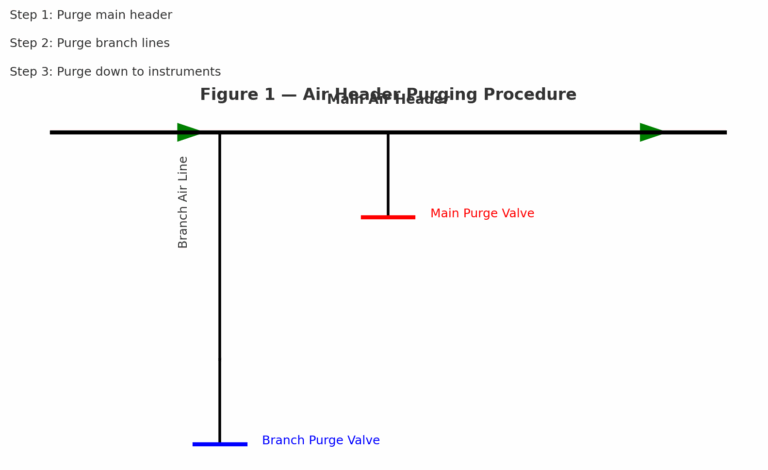

Air Supply Purging – Purge main and branch air headers to remove rust, silica dust, or other contaminants. Perform purging down to filter–regulator units of pneumatic valves and positioners.

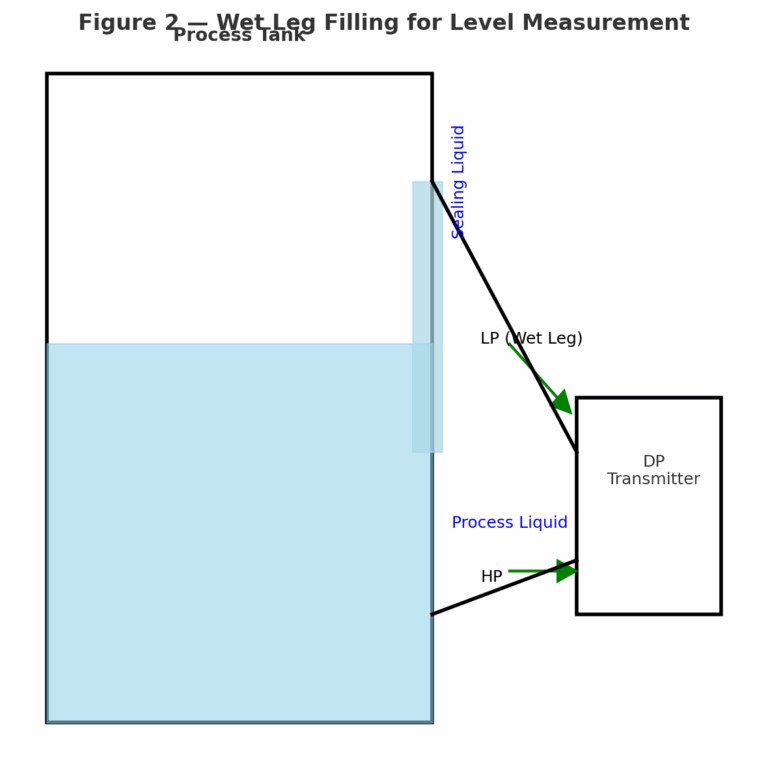

Differential Pressure Transmitters – For negative migration (wet leg) measurement, refill the impulse line with the appropriate sealing fluid.

Pressure and DP Transmitters with Seal Fluids – Ensure impulse lines are fully filled with sealing liquid before re-pressurization.

Leak Testing – Use soap solution to test pneumatic tubing joints for leaks.

Orifice Plate Installation – Confirm correct orientation and clean pipe wall. Align flange gaskets properly and open impulse valves after installation.

Control Valves – Match valve body arrow with process flow direction. Flush dirty service lines before valve installation.

Steam Flow Measurement – Use three-valve manifold procedure: keep equalizing valve open until impulse lines are fully condensed. Optionally use condensate pots for stable measurement.

Temperature Instruments – Ensure thermocouple polarity and RTD three-wire connections (A, B, C) are not confused.

Loop Checks and Calibration – Verify consistency between field instruments (primary), control room displays (secondary), and final control elements. Check that DCS/manual outputs match valve position indicators.

Control Loop Switching – Switch loops to automatic only after stable operation in manual mode.

Rotameters and Mechanical Flowmeters – Start with bypass valve open to flush possible debris, then gradually switch flow through the meter.

4. Safety Considerations

Always confirm absence of toxic, flammable, or pressurized fluids before dismantling or reconnecting instruments.

Use appropriate PPE (goggles, gloves, flame-resistant clothing) when handling high-temperature or high-pressure lines.

Maintain constant communication with operations and maintenance teams during critical stages.

5. Summary

Instrumentation personnel play a decisive role in ensuring smooth and safe plant shutdown and start-up. Key practices include:

Coordinating with process and maintenance teams.

Safely dismantling and reinstalling instruments.

Purging utilities and verifying connections.

Conducting loop checks and gradual transition to automatic control.

By following these guidelines, the risk of start-up delays, instrument failures, and safety incidents can be minimized, ensuring stable plant operation after maintenance.