1. Introduction

Instrumentation in chemical plants serves as the core of process control, safety monitoring, and quality assurance. The acceptance of instrumentation installation directly affects the stability, safety, and accuracy of subsequent operations.

Acceptance must strictly follow the “Code for Construction and Quality Acceptance of Automation Instrumentation Engineering” (GB 50093-2013) and special chemical industry regulations (e.g., explosion-proof, anti-corrosion, high temperature and pressure).

Key acceptance dimensions include:

Compliance of equipment

Accuracy of installation

Reliability of function

Safety conformity

Completeness of documentation

2. Pre-Acceptance Preparation: Baseline Verification

Before installation acceptance, the following must be confirmed:

Design documents: Instruments, specifications, ranges, and accuracy must match design; installation positions meet process needs; explosion-proof/anti-corrosion grades match environment.

Material verification: Factory certificates, calibration reports (CMC), explosion-proof certificates must be provided.

Visual inspection: Instruments and accessories free of damage, corrosion, or deformation.

Critical instruments: Random inspection records for safety-related devices.

3. Installation Acceptance: Core Procedures

3.1 Field Instrument Installation

Different instruments require specific checks:

Table 2 — Key Acceptance Points by Instrument Type

| Instrument Type | Critical Acceptance Points |

|---|---|

| Temperature | Insertion depth ≥ 1/3 pipe inner diameter; correct orientation; correct polarity (TC) or wiring (RTD). |

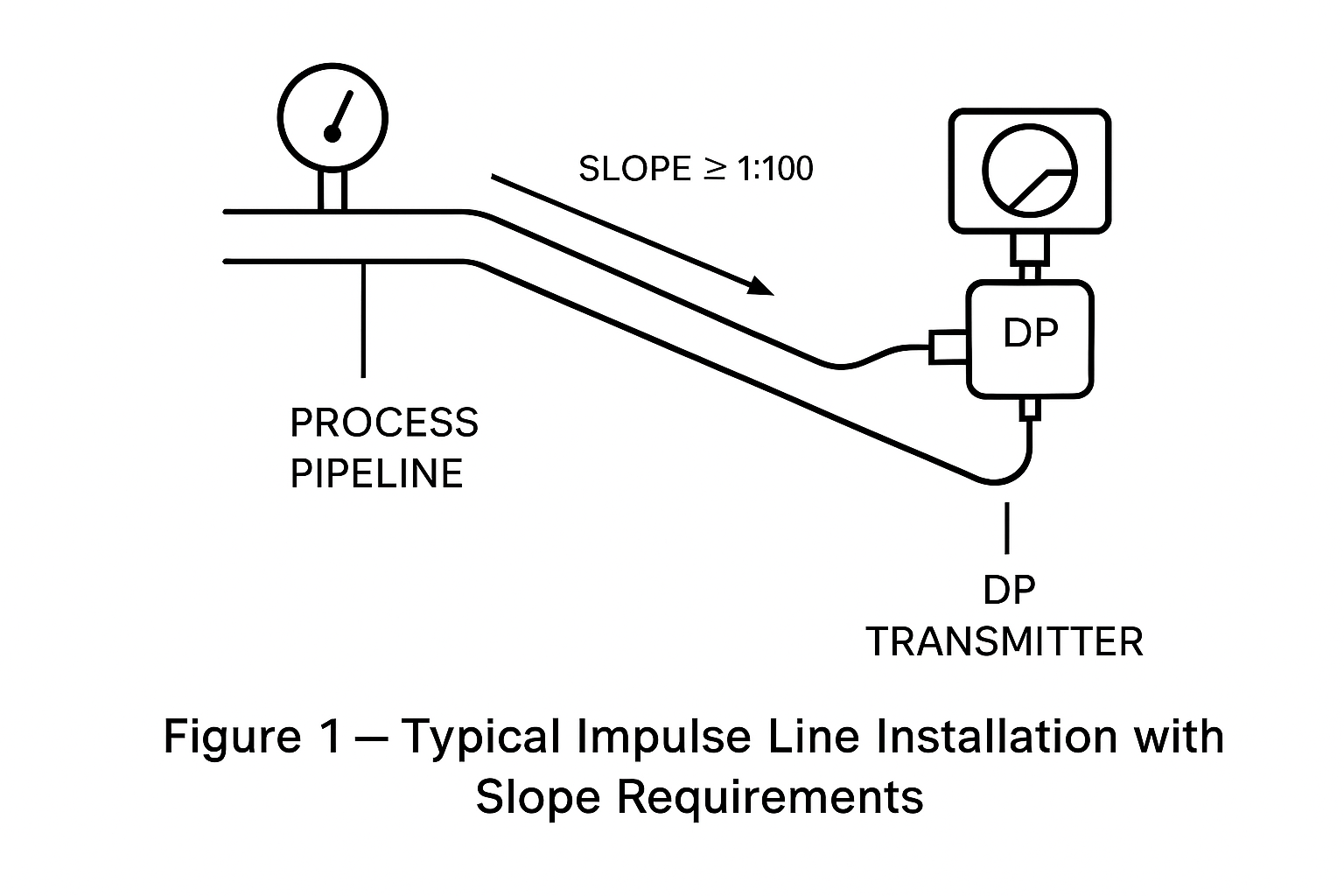

| Pressure | Tapping points away from turbulence; impulse line slope ≥1:100; isolation tank/heat tracing as required. |

| Flow | Straight run: e.g., orifice ≥10D upstream, 5D downstream; coaxiality ≤0.1D; EMF requires independent grounding ≤4Ω. |

| Level | Correct mounting height; recalculation based on medium density; flange sealing verified (e.g., nitrogen leak test). |

3.2 Piping and Cable Installation

Impulse & pneumatic lines: Material compatibility (PTFE for acids, SS for high T); welded joints without porosity; leak test (0.6 MPa, 24h, ΔP≤0.01 MPa).

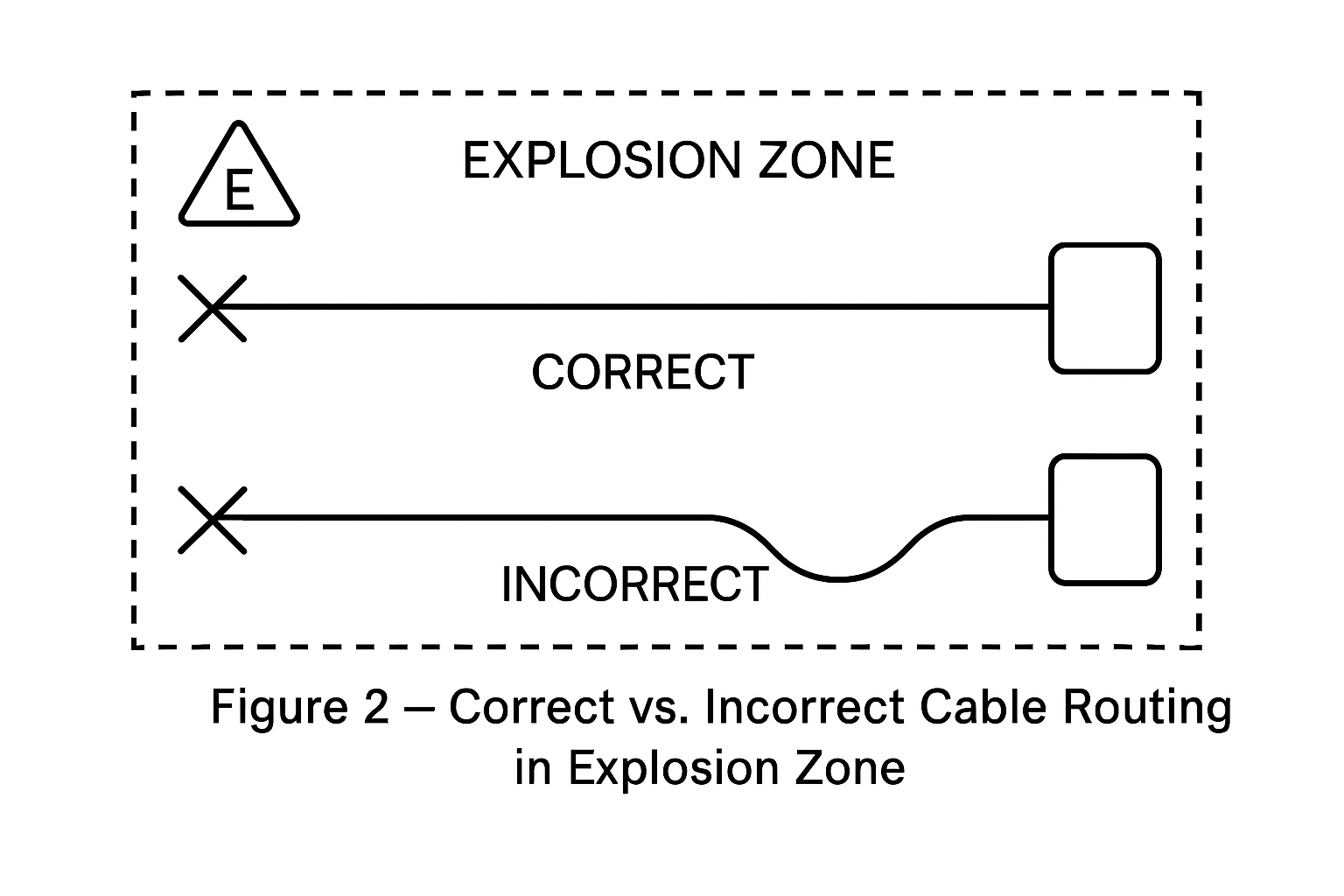

Cables & trays: Explosion-proof trays in hazardous zones; spacing ≥0.5 m from power cables; shielding grounded at one end only.

Marking: Clear instrument tag and cable ID at both ends.

3.3 Control Cabinets (DCS/PLC)

Vertical deviation ≤1 mm/m, door gap ≤2 mm.

Terminal wiring firm, consistent with drawings.

UPS voltage fluctuation ≤±5%, backup switching ≤10 ms.

4. Commissioning & Calibration: Functional Reliability

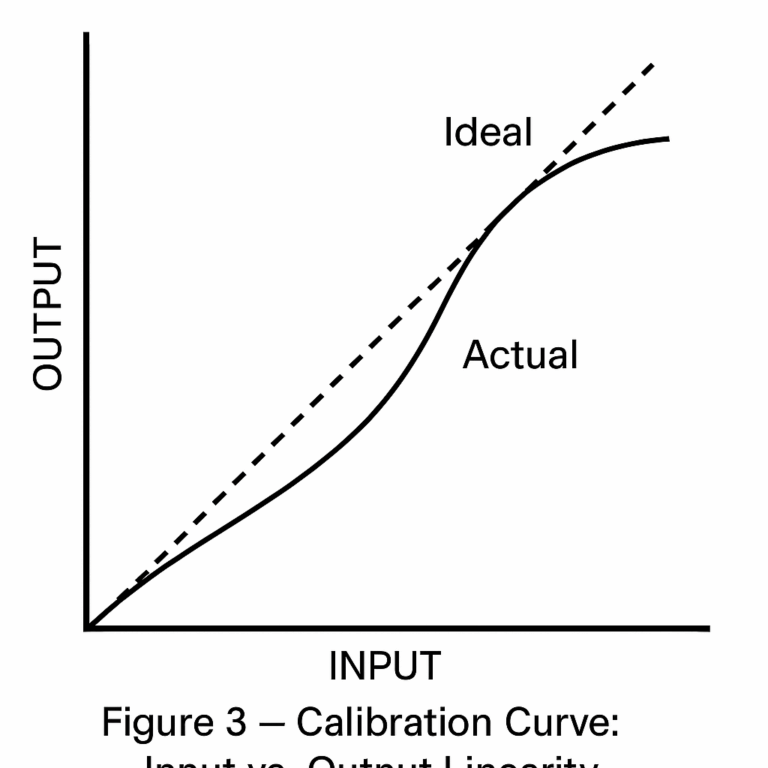

Single-instrument calibration:

Zero, span, linearity verified with at least 5 calibration points (0–100%).

Deviation ≤ instrument accuracy grade (e.g., 0.5% FS).

Hysteresis ≤½ of allowable error.

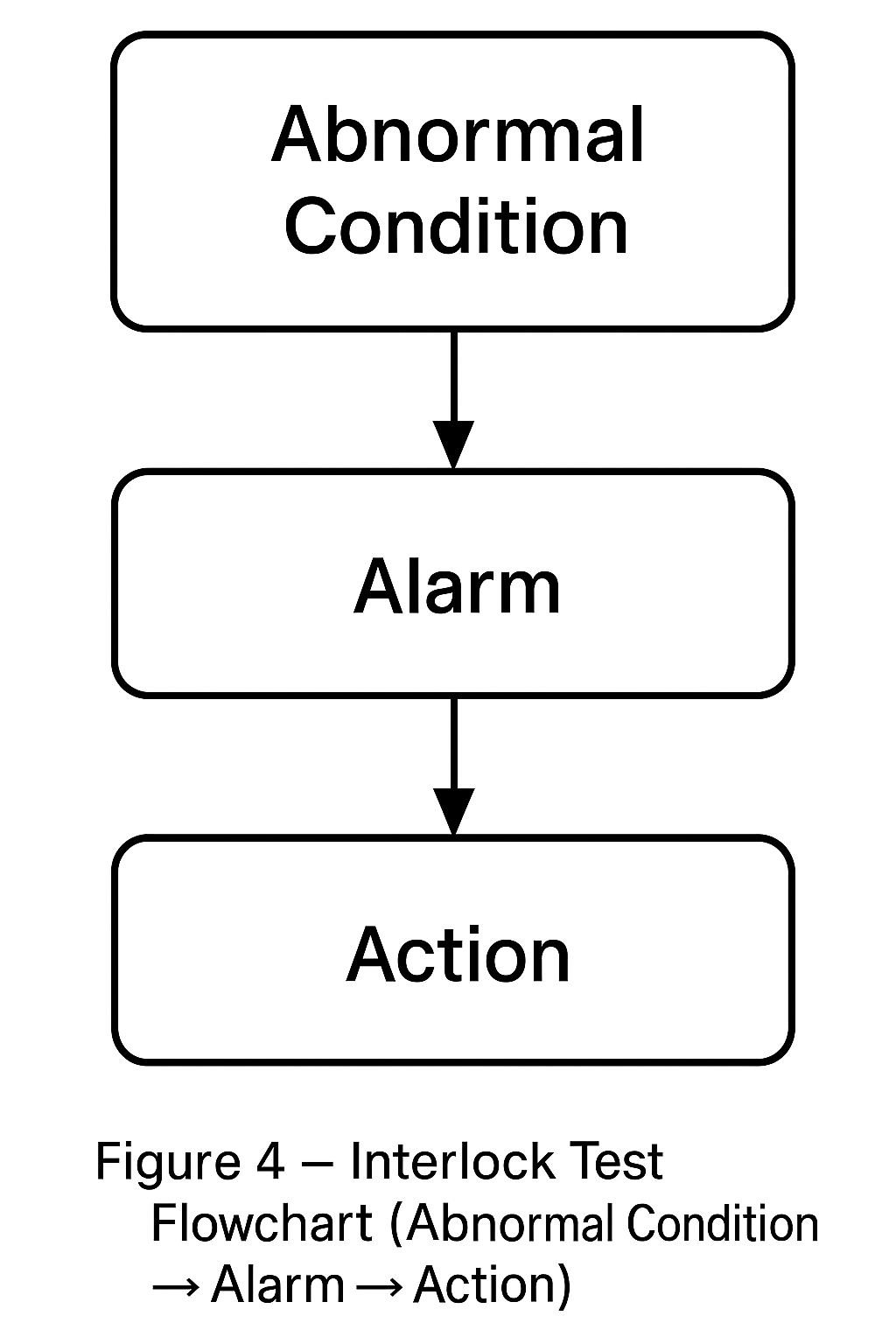

System loop checks:

Alarm and interlock response time ≤1 s.

Signal transmission deviation ≤0.2%.

DCS/PLC manual signal output matches actuator response (lag ≤0.5 s).

5. Safety & Environmental Acceptance

Explosion-proof: Instruments, junction boxes, cable glands meet GB 3836.1; Ex labels intact.

Anti-corrosion & protection: PTFE coating or stainless steel for corrosive service; rain/sun shields outdoors; thermal insulation in high-T zones.

Safety protection: Guardrails and ladders for elevated instruments; toxic gas detectors calibrated onsite, alarms set per standards (e.g., CO ≤30 ppm).

6. Documentation Acceptance

Essential documents for traceability and maintenance:

Design: P&IDs, installation drawings, datasheets, design change records.

Equipment: Certificates, calibration reports, explosion-proof certificates, material test reports.

Construction: Hidden work records, pressure/leak tests, welding records.

Commissioning: Calibration data, loop check reports, interlock test records.

O&M: Operation/maintenance manuals, spare parts list.

7. Acceptance Conclusions & Rectification

Acceptance signed jointly by owner, contractor, and supervisor.

Nonconformities → rectification notice, re-inspection within defined period.

Trial run (1–3 months) required; only after stable operation, project is handed over for production.

8. Common Causes of Non-Acceptance

Design mismatch: Wrong instrument range or material.

Installation errors: Incorrect tapping points, impulse line slope, inadequate grounding.

Calibration gaps: Incomplete or invalid calibration.

Safety violations: Non-Ex equipment in hazardous zones, missing protective measures.

Documentation issues: Missing or falsified certificates and records.

9. Conclusion

Instrumentation acceptance in chemical plants must follow a “full-process, step-by-step validation” approach:

Preparation stage ensures compliance of design and materials.

Installation stage secures precision and correctness of field work.

Commissioning stage validates accuracy and safety interlocks.

Final acceptance & trial run ensure long-term reliability.

Through this closed-loop process, chemical production can achieve stable operation, safety compliance, and measurement accuracy.