In industrial settings, there’s a dangerous “knee-jerk” reaction that can be costly:

Whenever the pressure transmitter readings fluctuate, technicians often suspect the device is faulty and immediately request a replacement.

What happens next? A new transmitter is installed, but within a few days, the same “drift” occurs again.

Engineer Li, with years of experience in the field, shares an important truth:

True pressure transmitter drift is rare in engineering environments. In fact, 90% of so-called “drift” issues are caused by system, environmental, or installation factors, not the transmitter itself. Replacing the device at the first sign of drift only masks deeper issues in the system and leads to unnecessary spare part costs.

Drift ≠ Faulty Transmitter

The most dreaded sight for field personnel is this type of curve:

The values don’t jump erratically but change slowly and steadily at an “extremely natural” rate. The trend follows a specific direction, often resembling the effects of electronic component aging. After a shutdown and re-pressurization, the zero-point refuses to return to normal.

While these symptoms seem to indicate a faulty device, they are actually the easiest to misinterpret. Such “smooth and rhythmic” changes are often due to external environmental factors impacting the device.

A truly faulty sensor usually shows a “cliff-like” failure—either it completely stops reading or the values jump to full scale erratically.

What’s Causing Your Transmitter to Drift?

Temperature

Even if pressure remains unchanged, changes in temperature will cause readings to fluctuate. Daily temperature variations, medium fluctuations, or a transmitter being too close to a high-temperature steam pipe can cause slight thermal expansion and contraction of the sensor structure.

Typical signs: Higher readings during the day and lower readings at night; normal readings when the device is first powered on, but drifting after running for a few hours.

Impulse Tubing

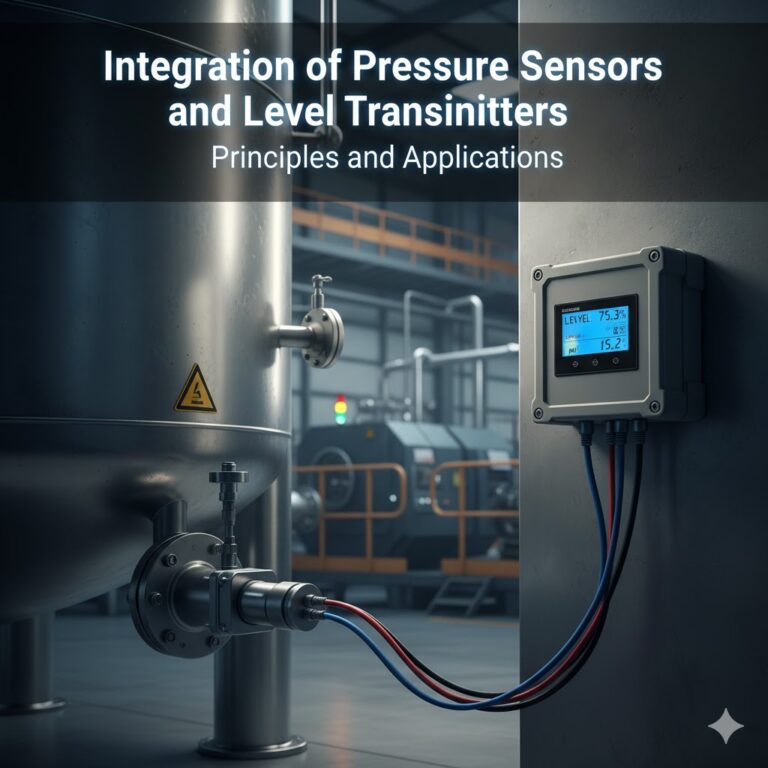

Many drift issues don’t originate in the transmitter itself but in the impulse lines connected to it.

Partial blockages: Medium crystallization or scaling delays pressure transmission.

Condensation: Water droplets in gas lines or air bubbles in liquid lines act as unstable weights, causing fluctuating zero-points.

Installation Stress

This problem is often overlooked by newcomers. Over-tightened threads, uneven mounting brackets, or high-frequency vibrations in pipes can transfer mechanical stress to the sensitive diaphragm through the device housing.

Symptoms: Initially accurate readings that gradually drift over time. When disassembled, the zero-point often returns to normal. This isn’t an electronic issue, but rather mechanical stress at play.

PLC Side Illusions

Sometimes, the transmitter outputs a steady 4-20mA signal, but the curve on the HMI drifts.

Poor grounding of the loop: Interfering signals are superimposed on the readings.

Temperature drift in AI modules: If the air conditioning in the cabinet fails, conversion errors in the analog-to-digital modules may present as “drift” in the readings.

Field Case Studies

Case 1: Day-to-Night Drift

During the day, the pressure reads 0.62 MPa, but at night, it reads 0.58 MPa. After replacing two transmitters, the problem persisted.

Conclusion: The transmitter was installed too close to a high-temperature pipe, leading to thermal compensation limits being exceeded.

Case 2: Failure to Return to Zero after Shutdown

After shutdown, the pressure reading remained at 0.03 MPa, which was deemed to be zero-point drift. Upon inspection, condensation was found in the impulse tubing.

Conclusion: The issue was due to liquid column static pressure interference, not a transmitter fault.

Case 3: Gradual Trend Increase

Despite stable operating conditions, the PLC’s trend curve kept climbing. The current loop was normal in the field test, but the issue was traced to temperature drift in the analog input modules.

Conclusion: The transmitter was falsely blamed for the drift.

The “Five-Step Troubleshooting Method” for Drift Issues

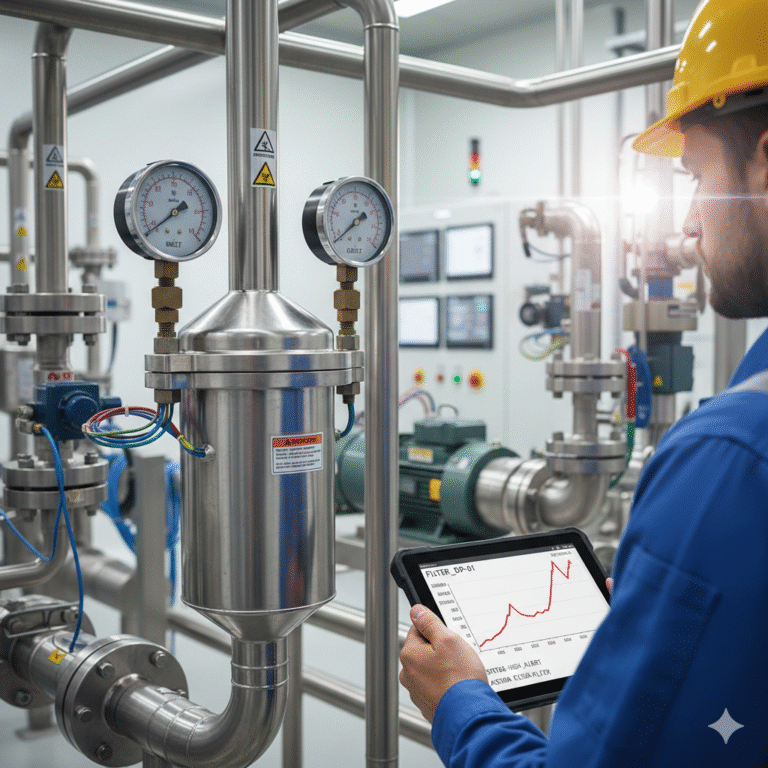

When encountering drift in the field, follow this sequence to diagnose the issue:

Confirm Operating Conditions (Look): Don’t just rely on the operator’s word that nothing has changed. Check if there have been any adjustments to process parameters.

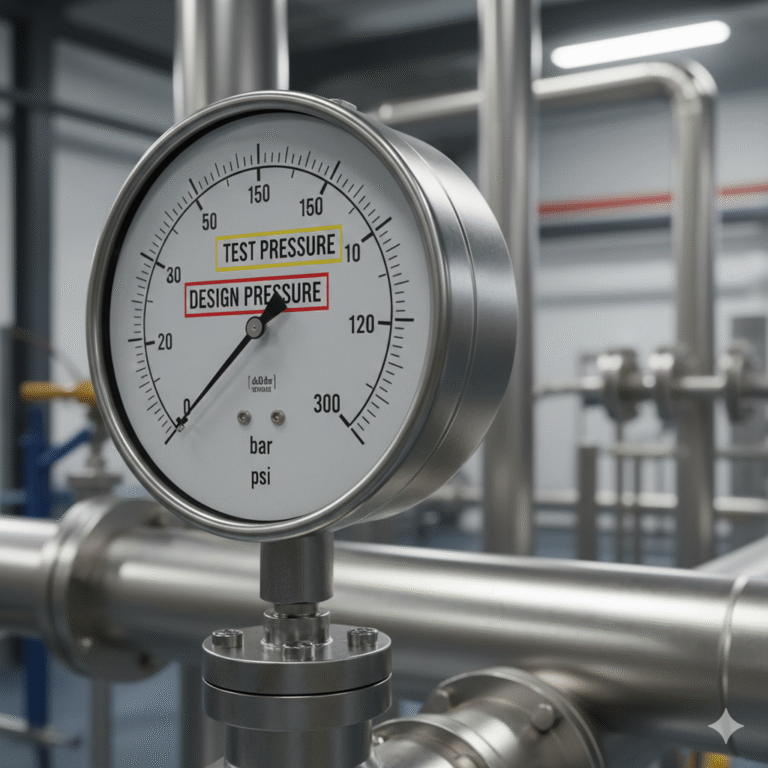

Local Comparison (Check): Use a precision pressure gauge to measure the actual pressure on-site and distinguish between process or signal issues.

Check Temperature (Heat): Look for any heat sources, excessive thermal insulation, or significant temperature differences in the environment.

Clear Impulse Tubing (Drain): Flush the tubing, drain condensate, and check liquid levels in condensate pots. Also, release any installation stresses.

Final Step: Adjust the Transmitter (Calibration): Only after confirming the above steps should you proceed with zero-point reset, calibration, or replacement validation.

Conclusion

A pressure transmitter is a passive device—it’s essentially a mirror. If the reflection appears distorted, the first thing to question is whether the position or environment is causing the issue, rather than automatically blaming the transmitter.

So, when you see drifting readings, it’s important to focus not on the quality of the transmitter, but on how deeply you understand the entire measurement system.