Introduction

Programmable Logic Controllers (PLCs) are widely used in industrial automation, making them an essential skill for many engineers and technicians. While some find PLCs challenging to learn, understanding the right methods can simplify the process significantly. This guide outlines practical steps to help anyone master PLCs efficiently.

1. Understand the Basics

To begin learning PLCs, you need to understand the fundamental concepts:

What is a PLC? A PLC is a digital computer used for automation. It monitors inputs, processes logic, and controls outputs.

Components of a PLC: Learn about its main parts, such as the CPU, input/output modules, power supply, and programming devices.

How it works: A PLC executes a program in a cycle, scanning inputs, processing logic, and updating outputs.

Familiarize yourself with basic electrical and programming principles to build a solid foundation.

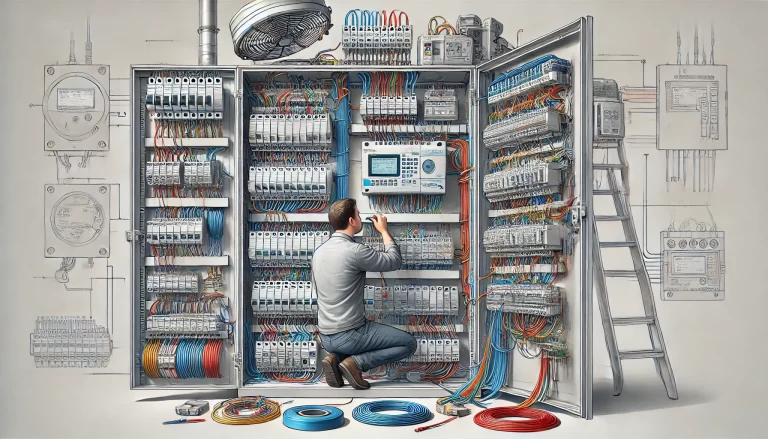

2. Choose the Right Equipment and Tools

Selecting reliable hardware and software is critical for effective learning:

Hardware: Opt for reputable brands like Siemens, Allen-Bradley, Mitsubishi, or Omron. Each has its strengths, such as Siemens’ broad support and Allen-Bradley’s ease of integration.

Software: Use beginner-friendly tools like TIA Portal, RSLogix, or GX Works. Ensure the software supports ladder logic and other common programming methods.

Simulation Tools: If hardware is unavailable, tools like Factory I/O or PLCSim are excellent for practice.

3. Learn PLC Programming

Programming is a critical part of mastering PLCs. Follow these steps:

Start Simple: Begin with ladder logic, the most common programming language for PLCs. Learn basic instructions like contacts (normally open/closed) and coils (outputs).

Understand Key Commands: Familiarize yourself with instructions such as:

LD(Load): Represents input signals.OUT(Output): Activates output signals.Timers and counters: For delayed actions or counting events.

Practice with Examples: For instance:

Use a ladder diagram to turn on a motor when a button is pressed.

Create a program to count products passing on a conveyor belt.

Analyze Logic: Break down the control requirements into clear, logical steps.

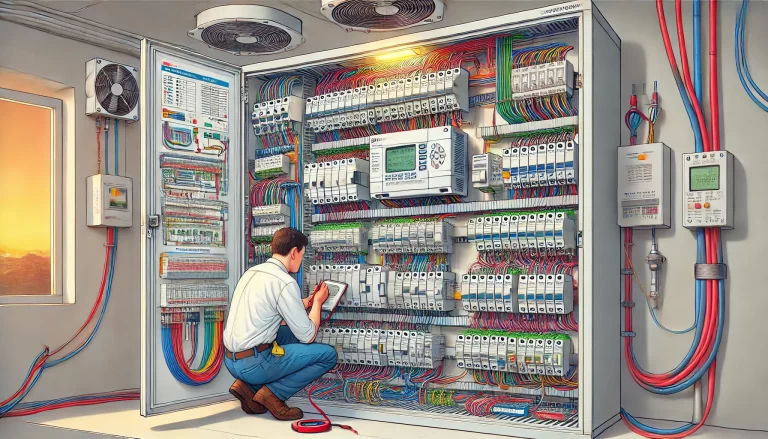

4. Hands-On Practice

Practical experience is key to mastering PLCs:

Small Projects: Start with simple projects like controlling lights or small motors. Gradually progress to more complex systems like traffic lights or conveyor systems.

Debugging Skills: Learn to troubleshoot errors using diagnostic tools in the software.

Simulations: Use software simulations to practice in a risk-free environment.

5. Collaborate and Seek Help

No one becomes an expert alone. Collaboration accelerates learning:

Join Communities: Participate in forums like PLCtalk.net or Reddit’s r/PLC to exchange ideas.

Ask Questions: Don’t hesitate to seek advice from experienced professionals.

Attend Workshops: Training programs and online courses often provide structured learning paths.

6. Develop a Systematic Approach

To make consistent progress, adopt a systematic approach:

Read Manuals: Thoroughly study the PLC’s documentation and understand its capabilities.

Plan Projects: Before programming, create flowcharts or diagrams outlining the control logic.

Test Programs: Test every program incrementally to ensure each part works as intended.

Summarize Learning: Keep notes on commands, error solutions, and best practices.

7. Avoid Common Pitfalls

Many learners struggle due to these common mistakes:

Skipping Basics: A weak understanding of fundamentals can lead to confusion later.

Lack of Practice: PLC programming requires hands-on experience. Watching tutorials alone isn’t enough.

Overcomplicating Projects: Start with simple projects before moving to advanced systems.

Conclusion

While learning PLCs may seem daunting at first, it becomes manageable with the right approach. Focus on understanding the basics, practicing regularly, and collaborating with others. Remember, patience and persistence are key. With time and effort, mastering PLCs is achievable for anyone.

Start your journey today and turn automation challenges into opportunities!