When installing industrial instruments in hazardous environments, ensuring explosion protection compliance is crucial. A common question arises:

“If an industrial instrument’s enclosure has already obtained an explosion-proof certificate, is it still necessary to obtain certification again after installation?”

Let’s explore this topic from a technical and regulatory perspective.

✅ 1. Does the Installation Alter the Certified Explosion-Proof Structure?

If the installation does not modify the certified design of the explosion-proof enclosure—such as drilling additional cable entries, altering sealing components, or replacing internal parts with uncertified equivalents—the original certification remains valid.

However, if:

The structure is modified,

New components are added,

Or the assembly is done outside of the manufacturer’s certified process,

Then the original certification may no longer be valid, and a new certification or third-party inspection is required.

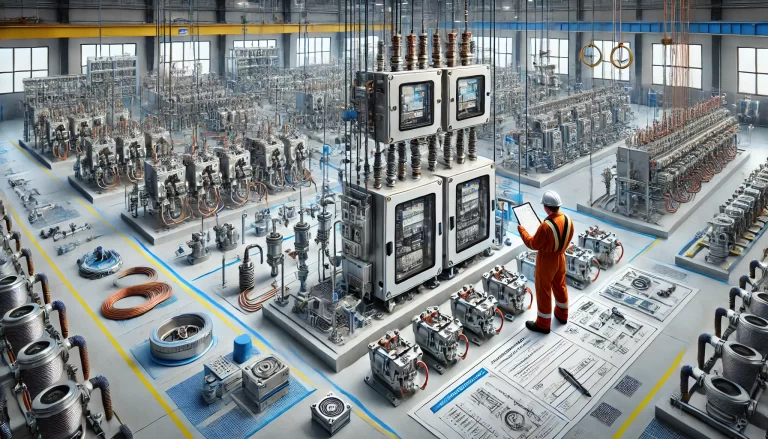

✅ 2. Part of a System or Standalone Device?

For standalone devices, using a certified explosion-proof instrument is generally sufficient if installed according to the manufacturer’s guidelines.

But if the instrument is integrated into a system (e.g., installed in an analyzer shelter, DCS cabinet, or hazardous-area junction box), the entire system may need to be evaluated to ensure all components meet the required explosion protection standards.

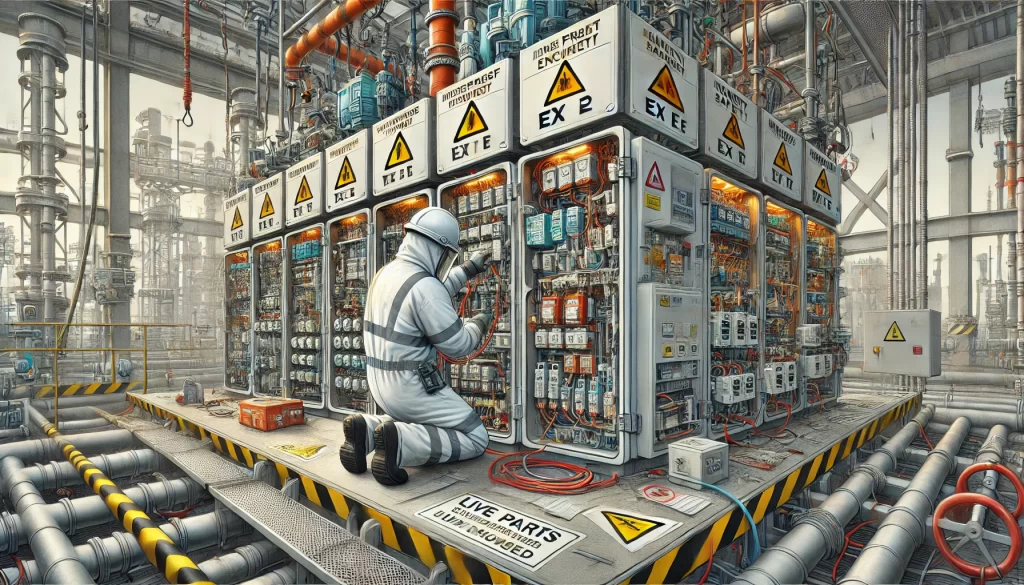

✅ 3. Explosion Zone Classification and Local Regulation

In Zone 0 or Zone 1 areas (defined by IEC or NEC codes), the rules are stricter. Authorities or project owners may require:

Full documentation proving compatibility of all installed components,

Correct use of Ex cable glands and connectors,

Verified grounding and bonding methods,

And possibly, a system-level Ex inspection report.

Even if individual parts are certified, the installation must meet the Ex system safety standards.

✅ 4. End-User or EPC Contractor Requirements

In many industrial projects, especially in the oil & gas, chemical, and mining industries, the owner or EPC contractor may require:

System-wide explosion-proof validation,

A Declaration of Conformity after installation,

Or third-party inspection and certification before commissioning.

Failure to comply can delay project acceptance or result in non-compliance penalties.

🔍 Conclusion

Is post-installation explosion-proof certification always required?

Not necessarily. It depends on:

Whether structural changes are made,

The complexity of the installation,

The Ex zone classification,

And the project or regulatory requirements.

💡 Recommendation for Installers and OEMs:

Maintain a full set of documentation: explosion-proof certificates, wiring diagrams, zone classification maps, and installation photos.

Avoid modifications to certified equipment unless approved by the original manufacturer.

If uncertain, consult with a certified third-party Ex inspection body before project handover.

If you need assistance determining whether your instrument installation requires additional certification, feel free to contact us. Our engineering team at Dalian Zero Instrument Technology Co., Ltd is ready to support your compliance needs.