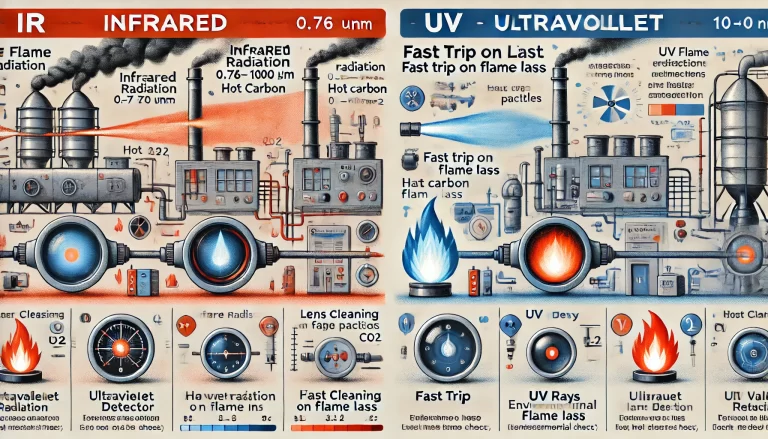

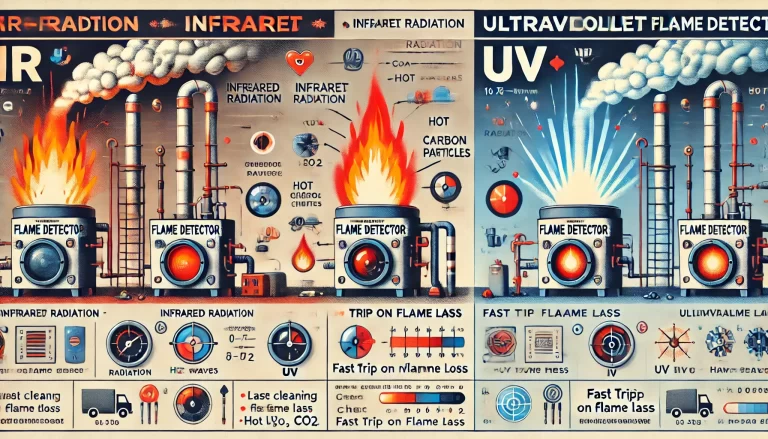

1) What each detector “sees”

Infrared (IR) flame detector: senses the thermal radiation emitted by flames (typ. 0.76–1000 μm). Strong response to hot carbon particles and H₂O/CO₂ emission bands during combustion.

Ultraviolet (UV) flame detector: senses high-frequency UV radiation from the combustion reaction (≈10–400 nm), prominent in clean gaseous flames.

2) Where each one excels (applications)

IR recommended for: diffusion flames of carbonaceous fuels (pulverized coal, coke, heavy oil), high-temperature furnaces/boilers/coking ovens, and dusty/smoky settings where IR is strong and stable.

UV recommended for: clean or gaseous fuels (natural gas, LPG/propane, light oil), gas turbines, flares/biogas systems—any scenario needing very fast trip on flame loss.

3) Interference profile (pros/cons)

IR

Pros: Resistant to visible light and general hot-body radiation with proper optical filtering; robust in smoky/dusty atmospheres.

Cons: Strong H₂O/CO₂ backgrounds or direct intense heat/light can raise noise; mirror/viewport fouling reduces signal.

UV

Pros: Ambient background is typically low because atmospheric absorption attenuates UV; ignores hot objects and lamps.

Cons: Easily masked by contamination (oil film, dust) on optics; UV from arcs/sparks can cause nuisance trips.

4) Response & lifetime

Response time: UV ≈ <10 ms (best for fast fuel shutoff); IR ≈ 50–100 ms (excellent for continuous, stable firing).

Service life: IR sensors typically 5–10 years and tolerate higher ambient temperatures; UV tubes often 2–5 years and are more temperature-sensitive.

5) Quick selection matrix

| Scenario | Fuel/Flame | Atmosphere | Priority | Pick | Note |

|---|---|---|---|---|---|

| Coal/solid fuel boiler | Carbonaceous diffusion | Dust/smoke present | Stability | IR | Strong IR from hot soot; UV often attenuated |

| Heavy-oil furnace/coker | Carbonaceous diffusion | Radiant, hot | Robustness | IR | Filter against hot-wall IR background |

| Gas turbine / clean gas boiler | Premixed/clean flame | Clean, low dust | Fast trip | UV | Millisecond response for safety interlock |

| Biogas flare | Clean gas | Outdoor | False-alarm immunity | UV | Beware welding arcs/electrical sparks |

| Mixed/variable fuels or high uptime safety | Mixed | Mixed | Redundancy | IR+UV (dual) | Channel voting improves reliability |

6) Routine maintenance checklist (suggested cadence)

Weekly – Clean optics

IR: wipe lens with anhydrous alcohol; replace if scratched.

UV: soft brush to remove dust/condensate; tiny films can fully block UV.

Monthly – Cabling & terminals

Inspect cables for heat aging/abrasion; verify continuity (≤ 1 Ω typical).

Retorque terminals; check shield single-point grounding and corrosion.

Daily – Status & trend

Verify RUN/ALARM indicators; log signal level (IR intensity / UV amplitude) and compare to baseline for early drift detection.

Quarterly – Environmental fitness

Heat: confirm insulation/cooling shrouds; add air purge if > 60 °C (IR) or > 80 °C (UV) around the head.

Moisture/corrosives: check seals, glands, gaskets; renew anti-corrosion coating where needed.

7) Calibration (use a flame simulator; remove safety interlock during test)

Tools: flame simulator (IR & UV modes), precision signal source, multimeter, log sheet.

IR channel

“Fire” point: Aim IR simulator (≈2–5 μm band, per fuel) at 30–50 cm; wait for stable reading; set Fire threshold ≈ 70–80% of that stable value to ensure margin.

“No-fire” point: Block optics with opaque cap; note background; set No-fire threshold ≈ 1.5× background so the system reliably trips on flameout.

UV channel

“Fire” point: Illuminate with ≈254 nm UV lamp at ~50 cm; adjust gain so output sits mid-range (e.g., 12–16 mA if 4–20 mA).

“No-fire” point: Block optics; trim zero to 4 mA (or designated “no-fire” state).

Dual (IR+UV)

Calibrate each channel separately, then test single-channel loss scenarios to verify voting/logic (e.g., IR masked → UV sustains “fire”; both masked → immediate “no-fire” alarm).

Intervals & records

Calibrate every 6 months, and immediately after sensor replacement, turnaround, or any false-/miss-trip event. Keep as-found/as-left thresholds, ambient data, and simulator certs in a traceable log.

8) Practical tips to reduce false trips

Keep optics clean; add air purge in dusty firing lines.

Shield from welding arcs and breaker-spark exposure (for UV).

Use proper optical bandpass filters and avoid direct view of hot refractory (for IR).

For critical burners, adopt dual-technology (IR+UV) with channel health diagnostics.