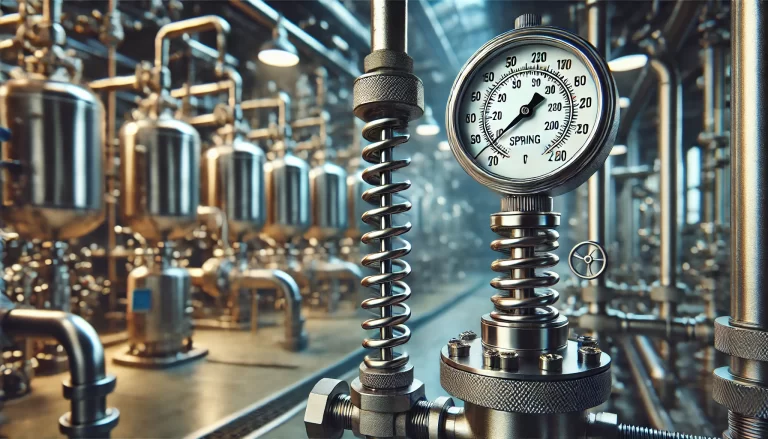

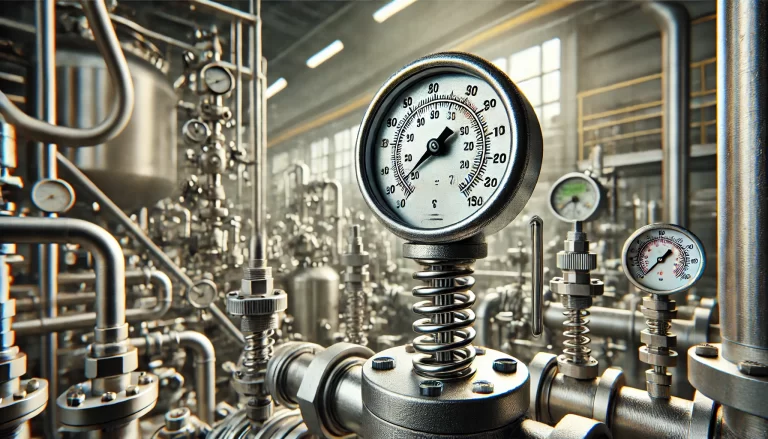

Spring thermometers are widely used industrial instruments for temperature measurement. They are particularly popular in industries such as manufacturing, energy, chemical processing, and food production. Their simplicity, reliability, and cost-effectiveness make them a preferred choice for monitoring and controlling temperature in various applications.

Principle of Operation

Spring thermometers operate based on the principle of thermal expansion in metals. The primary sensing element, such as a spiral spring or bimetallic strip, expands or contracts in response to temperature changes. This mechanical deformation is transmitted through a mechanical linkage to a pointer on a dial, which then indicates the temperature.

- Sensing Element: Typically made of high-quality metallic materials, which expand predictably with temperature changes.

- Mechanical Transmission: The deformation of the sensing element is converted into rotational motion using gears and linkages.

- Temperature Display: A calibrated dial indicates the temperature, providing an easy-to-read and precise measurement.

Key Features

1. Mechanical Simplicity

- Entirely mechanical operation; no need for electrical components or power supply.

- Easy to maintain due to the absence of complex electronic systems.

2. Ease of Use

- Direct temperature reading via the analog dial.

- No additional equipment or software required for operation.

3. Durability

- Resistant to harsh environments, including high temperatures, humidity, and corrosive conditions.

- Shock-resistant designs are available for applications with vibrations or impacts.

4. Versatility

- Applicable across a wide range of temperatures and industries.

- Multiple installation configurations cater to diverse setups.

Applications

Spring thermometers are essential for a variety of temperature measurement tasks:

1. Industrial Applications

- Monitoring temperatures of machinery, pipes, and vessels in manufacturing facilities.

- Ensuring safe operating conditions for heat-sensitive processes.

2. Chemical Industry

- Measuring the temperature of liquids and gases during chemical reactions.

- Ensuring stability in sensitive processes to avoid safety risks.

3. Food and Beverage

- Monitoring temperatures during cooking, cooling, and storage.

- Maintaining compliance with food safety standards.

4. HVAC Systems

- Monitoring boilers, water heaters, and heat exchangers.

- Ensuring efficient operation in heating and cooling systems.

Types of Spring Thermometers

Spring thermometers can be classified based on their construction and usage:

1. By Sensing Element

- Spiral Spring Thermometers: Suitable for high-temperature ranges due to robust design.

- Bimetallic Thermometers: Ideal for medium to low-temperature ranges, offering high accuracy.

2. By Mounting Style

- Radial Type: The dial is aligned straight with the probe, suitable for compact spaces.

- Axial Type: The dial is perpendicular to the probe, providing easy visibility when mounted vertically.

- Universal Joint Type: Adjustable dial angles allow for flexible reading orientations.

3. By Usage Environment

- Standard Models: For general-purpose applications.

- Vibration-Resistant Models: Designed for environments with mechanical vibrations.

- Corrosion-Resistant Models: Built with special materials to handle aggressive chemicals.

Technical Specifications

- Temperature Range: -40°C to 600°C (specific ranges vary by model).

- Accuracy: ±1% to ±2% of the full-scale range.

- Dial Sizes: Common diameters include 63mm, 100mm, and 150mm.

- Connection Threads: Standard options include G1/2, M20×1.5, and NPT threads.

- Case Material: Often stainless steel for durability and corrosion resistance.

- Protection Rating: Available in IP-rated models for use in dust or water-prone environments.

Advantages

- Cost-Effective: Affordable compared to electronic temperature sensors and gauges.

- Reliable: Long operational lifespan with minimal maintenance requirements.

- Independent Operation: No reliance on external power sources or wiring.

- Customizable: Wide range of configurations to meet specific application needs.

Maintenance Tips

To ensure accurate and reliable operation, regular maintenance of spring thermometers is recommended:

- Calibration: Periodically verify the thermometer against a standard to maintain accuracy.

- Protection: Avoid exposure to extreme shocks or mechanical stress to prevent damage.

- Material Selection: Use corrosion-resistant models in chemically aggressive environments.

- Inspection: Check for dirt or debris on the dial and probe, as these can affect readings.

Conclusion

Spring thermometers offer a robust and cost-effective solution for temperature measurement in a wide variety of industrial and commercial applications. Their mechanical simplicity, durability, and versatility make them indispensable tools for ensuring process safety and efficiency. Whether you need a standard model for general use or a specialized version for challenging environments, spring thermometers provide reliable performance without breaking the budget.