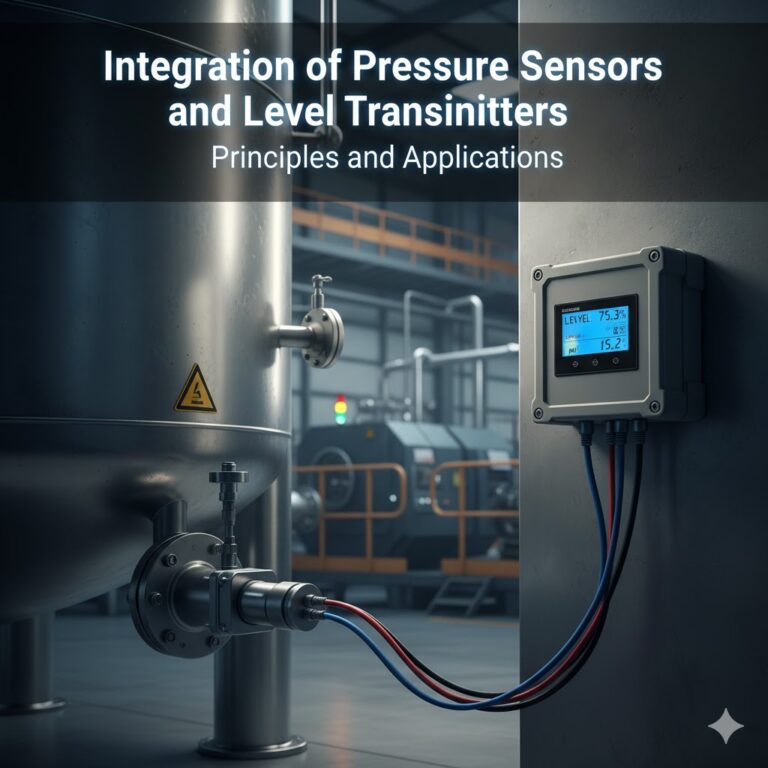

In the field of industrial measurement, integrating pressure sensors with level transmitters is a fundamental technique for accurately measuring fluid levels. This integration leverages the principle that liquid static pressure is proportional to the liquid height, converting pressure signals into remote, precise level data. The process can be broken down into three core steps: signal acquisition, signal processing, and signal output.

1. Core Integration Principle: Translating Pressure to Level

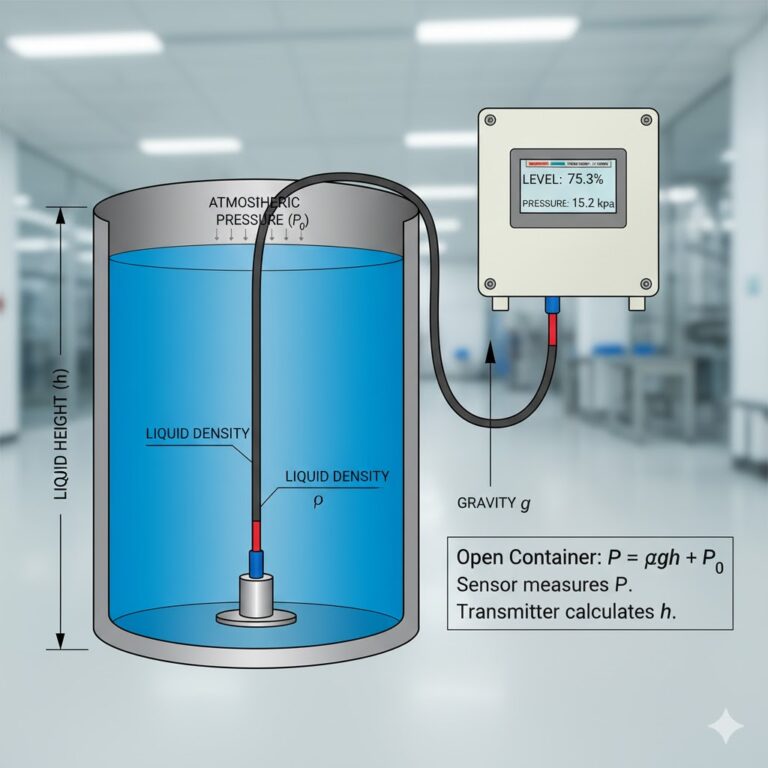

Liquid in a container generates static pressure, described by the formula:

Where:

is the total pressure

is the liquid density

is the gravitational acceleration

is the liquid height

is the atmospheric pressure above the liquid surface.

The integration of pressure sensors and level transmitters works by reversing this formula to derive liquid level. Here’s how the two components work together:

Pressure Sensor: Signal Acquisition

The pressure sensor is in direct contact with the liquid (or via a capillary tube in indirect contact), converting the generated static pressure into a weak electrical signal (e.g., mV or mA).Level Transmitter: Signal Processing and Output

The level transmitter receives the raw signal from the sensor. It amplifies and compensates for factors such as temperature or zero-point drift. Then, using predefined liquid density () and container height parameters, the transmitter converts the pressure signal into a corresponding liquid level signal, outputting standard industrial signals (e.g., 4-20mA, 0-10V, or RS485 digital signals) for display or control.

2. Three Typical Integration Installations (By Container Type)

The sealing status and structure of the container determine the installation and integration logic, which directly impacts the measurement accuracy:

Open Containers (e.g., open water tanks, pools)

Integration Logic: Only the liquid static pressure needs to be measured since atmospheric pressure affects both the sensor and the liquid surface, cancelling each other out.

Installation:

The pressure sensor is installed at the bottom of the container or at a preset low point, directly in contact with the liquid to measure static pressure

The sensor’s signal output is connected to the level transmitter’s input, which compensates for atmospheric pressure and calculates the liquid height

Closed Containers (e.g., pressure vessels, reactors)

Integration Logic: Measures both liquid static pressure and the gas-phase pressure above the liquid surface to avoid interference.

Installation (Dual Sensor Setup):

Lower Sensor: Installed at the bottom to measure the total pressure

Upper Sensor: Installed at the top of the container to measure the gas-phase pressure

The signals from both sensors are fed into the level transmitter, which subtracts the gas-phase pressure to accurately calculate the liquid height

Corrosive/Viscous Liquids (e.g., acidic solutions, slurries)

Integration Logic: The pressure sensor is protected from direct contact with corrosive or viscous media using a capillary tube and isolating diaphragm.

Installation:

A “diaphragm isolated pressure sensor” is installed at the bottom of the container. The diaphragm transfers the liquid pressure to the isolation liquid inside the sensor, which then converts it to an electrical signal.

The transmitter needs to compensate for the density of the isolation liquid to ensure accurate level measurement.

3. Key Parameters for Successful Integration: Matching for Precision

The accuracy of pressure sensor and level transmitter integration depends not just on individual components but on how well their parameters match. Key considerations include:

Range Matching:

The pressure sensor’s range should cover the maximum static pressure at the highest liquid level (Pmax=ρghmax) to prevent overloading or underperformance. The level transmitter should be set to match the sensor’s output range (e.g., a sensor output of 0-5V corresponding to 0-1MPa pressure).Accuracy Matching:

The sensor’s accuracy (e.g., 0.1% FS) should be equal to or higher than that of the transmitter (e.g., 0.2% FS) to avoid wasting precision by pairing a high-accuracy transmitter with a low-accuracy sensor.Environmental Compatibility:

Both the sensor and the transmitter must be rated for the operating environment. For high-temperature environments, high-temperature sensors and transmitters should be selected, and for hazardous areas, explosion-proof versions are required.

4. Typical Application Scenarios: Real-World Benefits

Here are some key industries where pressure sensors and level transmitters are successfully integrated to ensure efficient operation:

Water Treatment Industry:

In open water tanks, pressure sensors and level transmitters are used to monitor water levels. When the level drops below a preset threshold, the transmitter triggers the pump to fill the tank.Oil and Gas Industry:

In closed storage tanks, dual pressure sensors and level transmitters monitor crude oil levels. The gas-phase pressure is subtracted from the total pressure to ensure precise level measurement, preventing tank overflow or emptying.Food and Pharmaceutical Industries:

In sanitary stainless steel tanks, pressure sensors and level transmitters (with hygienic certifications) monitor the level of sauces or pharmaceutical liquids. This prevents contamination and ensures compliance with industry standards.