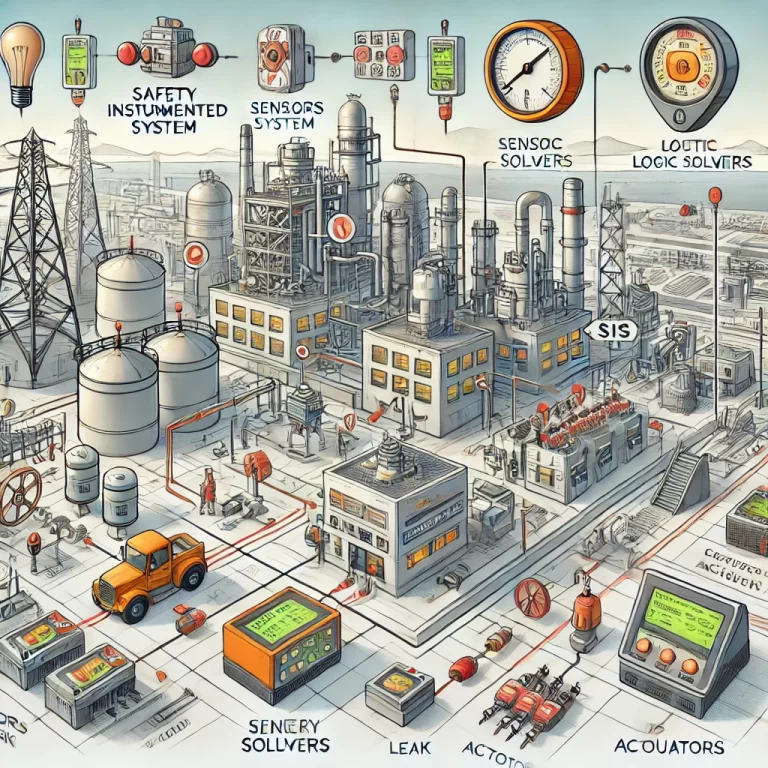

In the realm of chemical plant operations, the discussion about integrating Safety Instrumented Systems (SIS) with Central Control Systems (CCS) has gained attention. These two systems serve critical but distinct roles, and while integrating them might seem efficient, it poses significant technical and safety challenges. This article delves into the differences between SIS and CCS, the risks of merging them into a unified system, and potential strategies for effective integration without compromising safety or control integrity.

Key Functions and Differences

Safety Instrumented System (SIS): SIS is designed to monitor critical parameters and take necessary protective actions to prevent hazardous events. It acts as an independent layer of protection in the safety hierarchy, ensuring the safety of personnel, equipment, and the environment. When an unsafe condition is detected, SIS initiates responses such as emergency shutdowns (ESD) or isolation procedures to mitigate risks. The core philosophy behind SIS is to function independently from regular operational controls to remain reliable even if other systems fail.

Central Control System (CCS): CCS, or process control systems, focus on the operational management of a plant, enabling precise control over processes such as temperature, pressure, flow rates, and chemical reactions. The primary goal of CCS is to optimize production, maintain product quality, and ensure efficient operations. While CCS can include safety alarms and monitoring features, its design does not prioritize fail-safe actions; instead, it emphasizes continuous and efficient control.

Risks of Full System Merging

Despite the technological advancements that make integration feasible, merging SIS and CCS into a single control system is generally not recommended. Here are the key risks:

Loss of Independent Safeguards: One of the main principles of safe chemical operations is maintaining independent layers of protection. SIS is designed to act independently of other systems to ensure it can perform its safety functions even when other parts of the plant’s control architecture experience failures. Combining SIS with CCS could compromise this independence and increase the risk of common-cause failures.

Conflicting Priorities: CCS is designed for process control and optimization, which prioritizes maintaining stable operations and maximizing production. Conversely, SIS focuses solely on safety and may take actions that abruptly disrupt production (e.g., initiating an emergency shutdown). Integrating these systems could lead to conflicts where safety protocols might be delayed or overridden by process control objectives, potentially endangering the facility.

Regulatory and Compliance Issues: Industry standards such as IEC 61511 and IEC 61508 emphasize the importance of separation between safety systems and process control systems. These standards are designed to ensure that safety functions are not compromised by system integration. Full integration of SIS and CCS may violate compliance with such regulations, leading to legal and operational repercussions.

Effective Integration Strategies

While merging SIS and CCS into a single system is not advisable, there are strategies for integrating these systems to improve overall plant operations and information flow while retaining their distinct roles:

Communication Interfaces: Integrating SIS and CCS through reliable communication interfaces allows the two systems to share data without losing their independent functionality. Protocols such as OPC (Open Platform Communications) can facilitate seamless data exchange, enabling CCS to display real-time SIS status and provide operators with comprehensive monitoring dashboards.

Shared Human-Machine Interfaces (HMIs): A shared HMI can display both CCS and SIS data in a unified manner, allowing operators to monitor process variables and safety parameters simultaneously. This approach improves situational awareness and response times without compromising the independence of the SIS logic.

Coordinated but Independent Logic: Designing the systems to coordinate actions through pre-defined interlocks and sequences can enable CCS to respond to SIS-initiated safety trips in a controlled manner. This method ensures that SIS retains its authority over safety functions while enabling CCS to manage the process implications effectively.

Regular Testing and Validation: To maintain the integrity of both systems, regular testing and validation must be conducted. This ensures that the communication interfaces and integrated operations do not introduce vulnerabilities or unforeseen interactions that could compromise safety.

Conclusion

The integration of SIS and CCS in chemical plant operations is a nuanced decision. While technological advancements allow for more cohesive data sharing and operator interface designs, full system merging is generally not advised due to the risks to safety and regulatory compliance. Instead, employing strategies that preserve the independence of SIS while enabling data and functional coordination with CCS offers a balanced approach. By doing so, plants can optimize both safety and efficiency, ensuring a safe and productive operational environment.