1. Instrument Body and Accessories Inspection

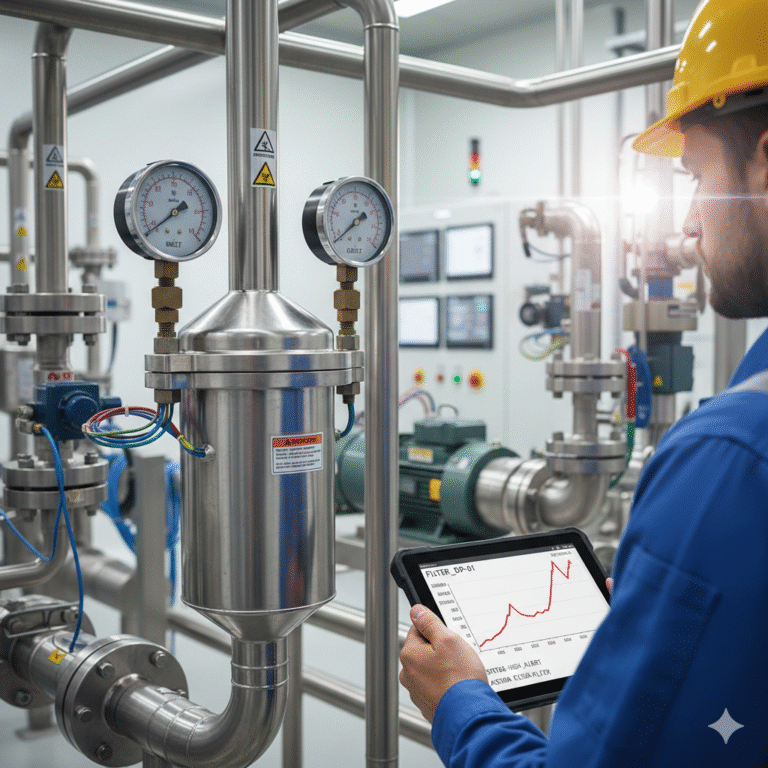

1.1 Pressure Gauges / Differential Pressure Gauges

Inspection Points:

Check whether there is condensation, water droplets, or moisture inside the gauge.

Ensure the pointer is intact, without falling off, sticking, or abnormal movement.

Confirm the dial scale is clear and legible.

Inspect the gauge body for deformation, mechanical damage, or corrosion.

1.2 Pressure Gauges (Local Indicators)

Inspection Points:

Verify that calibration labels are complete, clear, valid, and not expired.

Check for water ingress or internal moisture.

Inspect threaded connections for oil leakage or process leakage.

Confirm electrical contact pressure settings are consistent and correct.

Check for severe corrosion on local pressure gauges.

Ensure there is no abnormal vibration during operation.

1.3 Valve Positioners

Inspection Points:

Ensure cable glands are firmly tightened and wiring is secure.

Check for air leakage or mechanical damage.

Verify reliable mounting between the positioner and control valve.

1.4 Transmitters (Pressure / Level / Temperature)

Inspection Points:

Confirm the protection tube union joint is properly tightened.

Check for signs of rainwater entering the protection tube.

Inspect the housing for condensation or moisture.

Ensure the display is clear and readable.

Verify that transmitter stands in LPG sphere tank areas are firmly fixed.

Check for abnormal vibration or physical damage.

1.5 Valves and Valve Accessories

(including 2-valve manifold, 3-valve manifold, drain valves, Fisher on-off valves)

Inspection Points:

Check for leakage at upstream connections of the two-valve manifold.

Confirm the balance valve of the three-valve manifold is in the correct operating position.

Ensure drain valve handles are intact.

Check for excessive vibration of the valve body.

Inspect tee connections for air leakage.

Verify operating air pressure is within normal range.

Ensure pressure gauges on filter regulators of Fisher on-off valves are complete and not missing.

Inspect valve stem packing for air leakage.

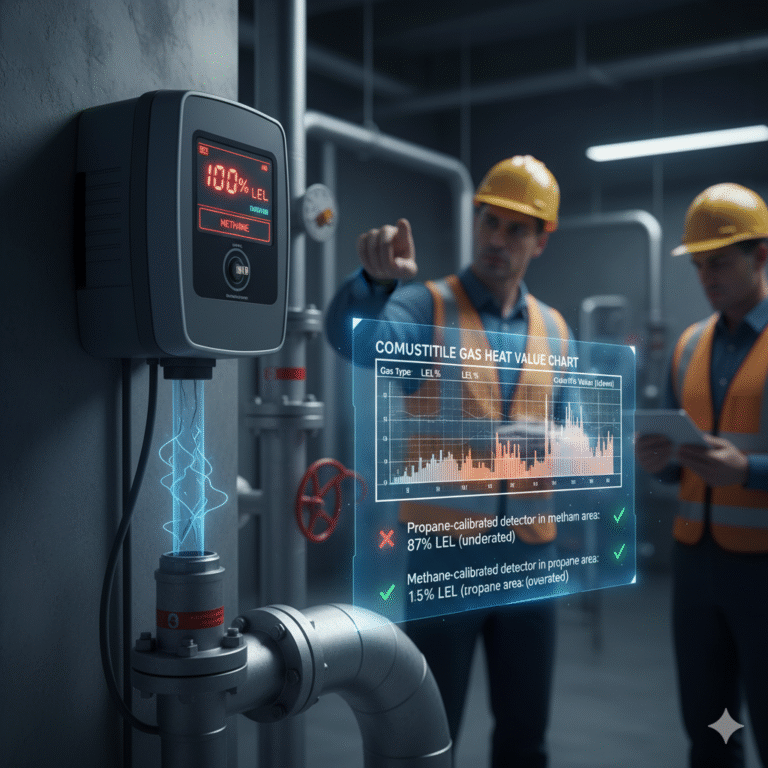

1.6 Gas Detectors and Audible-Visual Alarms

Inspection Points:

Check for physical damage or water ingress.

Inspect internal condensation or moisture.

Verify alarm functions through sampling tests when applicable.

Ensure devices are firmly mounted without looseness.

1.7 Temperature Instruments

Inspection Points:

Ensure extension cables are not in contact with high-temperature pipe surfaces.

Verify temperature readings are reasonable and stable.

Check for damage caused by rainwater ingress or insulation failure.

2. Impulse Tubing and Piping Inspection

2.1 Impulse Lines / Pressure Tubing

Inspection Points:

Check for loose, disordered, or unsupported tubing.

Inspect for excessive vibration.

Verify all connections are free of leakage.

Ensure no friction with cables or air supply tubing.

Check for aging, cracking, or mechanical damage.

2.2 Drain Plugs and Air Receiver Drain Valves

Inspection Points:

Inspect drain plugs for leakage.

Confirm drain valves are fitted with proper threaded plugs.

Ensure drain outlets are not blocked.

2.3 Capillary Tubes

Inspection Points:

Ensure capillaries are not scattered on the ground.

Verify proper coiling and fixation.

Inspect for deformation, aging, or crushing.

2.4 Vent Ports and Exhaust Outlets

Inspection Points:

Check for missing filters or silencers.

Ensure rain caps are installed and intact.

Verify no foreign materials block the exhaust outlet.

2.5 Cable Trays and Covers

Inspection Points:

Ensure tray covers are complete and properly installed.

Check for deformation or corrosion.

Inspect for internal debris or water accumulation.

3. Electrical and Grounding System Inspection

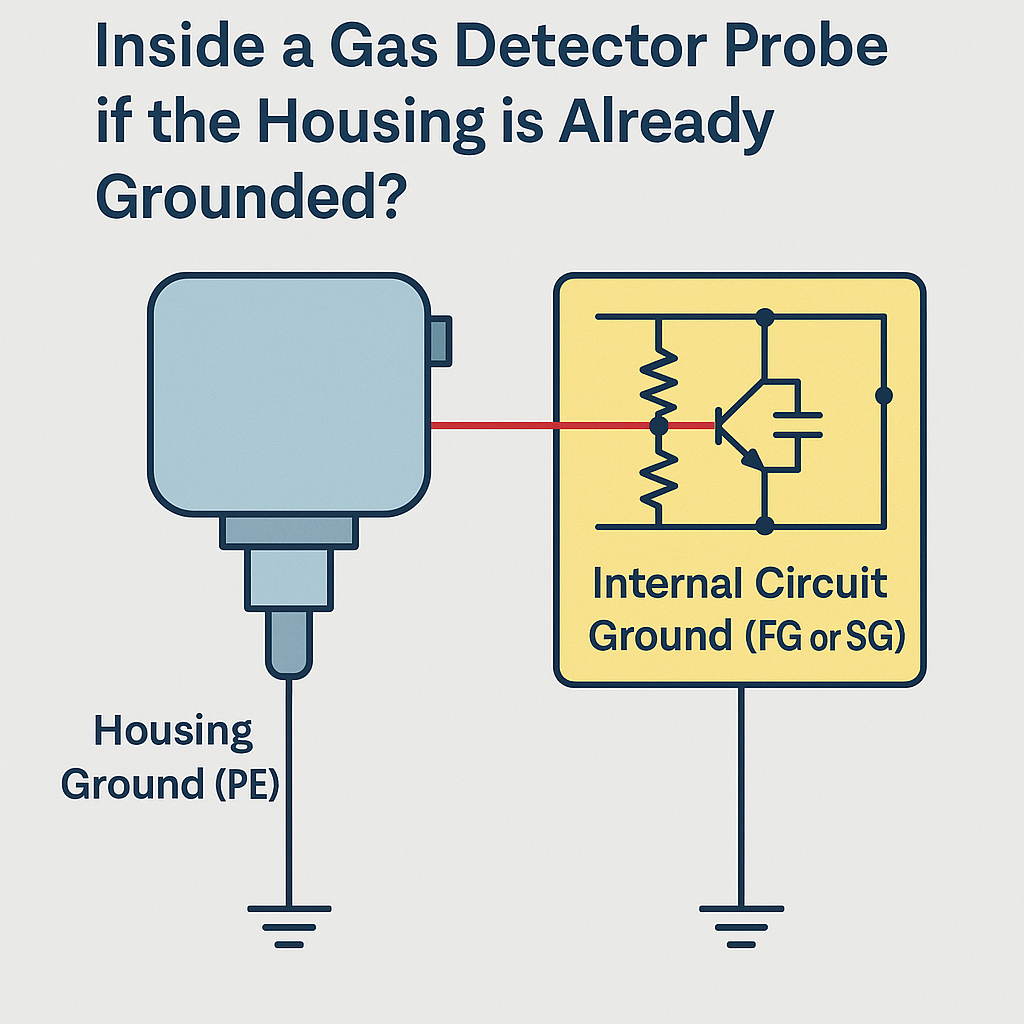

3.1 Grounding System

Inspection Points:

Verify grounding wires on instrument housings are securely connected.

Ensure solenoid valve enclosures are properly grounded.

Confirm bonding jumpers are installed on cable trays.

Check that cable grounding is reliable and continuous.

Avoid multiple instruments sharing a single grounding point.

Inspect grounding conductors for corrosion, aging, or damage.

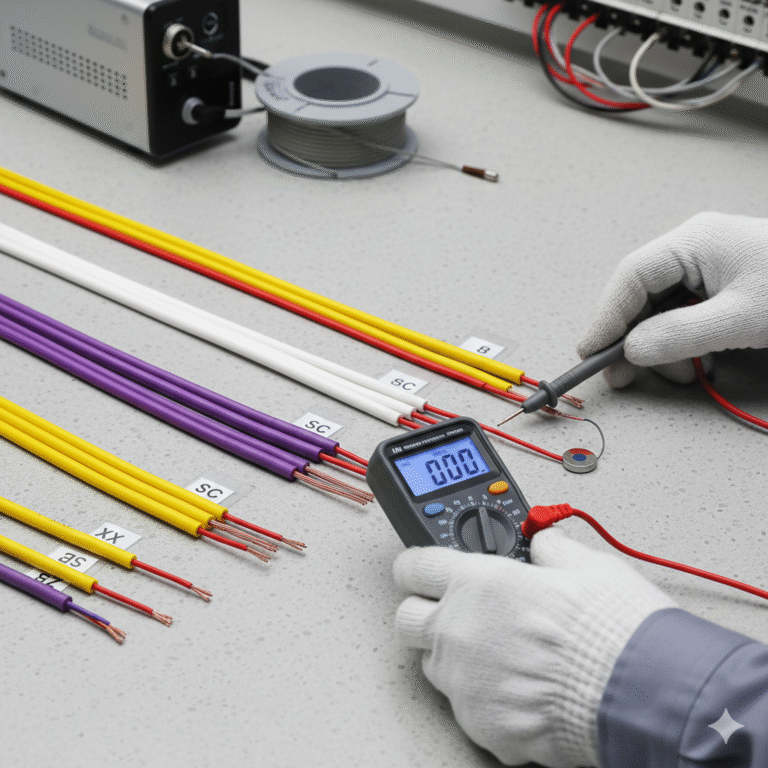

3.2 Cables and Wiring

Inspection Points:

Ensure cables are properly tied and supported.

Avoid contact with vibrating pipelines.

Prevent friction with pneumatic tubing.

Inspect cable sheaths for aging or mechanical damage.

Check terminal connections for looseness.

3.3 Limit Switch Covers

Inspection Points:

Check for deformation or water ingress.

Ensure sealing is effective.

Verify terminal connections are tight.

4. Safety Protection and Identification

4.1 Explosion-Proof Facilities

Inspection Points:

Confirm certified explosion-proof plugs are used.

Plastic or non-explosion-proof plugs are strictly prohibited.

Verify sealing integrity of explosion-proof fittings.

4.2 Tags and Identification Plates

Inspection Points:

Ensure calibration and inspection labels are present and legible.

Verify labels are within validity period.

Check tag plates for secure installation.

Replace aged cable ties with stainless steel ties.

Confirm tag information matches the actual instrument.

4.3 Protective Components

Inspection Points:

Inspect rain covers and protection tubes for integrity.

Check instrument stands and brackets for corrosion or damage.

5. Environment and General Inspection

5.1 Surrounding Environment

Inspection Points:

Verify ambient temperature (e.g., air-conditioning) is within acceptable range.

Check for standing water, debris, or contaminants.

Identify environmental factors affecting instrument performance, such as humidity, corrosion, or high temperature.

5.2 Equipment Stability and Reinforcement

Inspection Points:

Confirm typhoon or wind reinforcement measures are completed where required.

Check instruments, stands, and supports for looseness or vibration.

Inspect structural components for corrosion or deformation.

5.3 Other Abnormal Conditions

Inspection Points:

Check for foreign objects attached to instruments.

Listen for abnormal noise or odor during operation.

Identify abnormal signal fluctuation or unstable readings.

6. Common Inspection Issues and Corrective Actions

| Inspection Issue | Corrective Action |

|---|---|

| Moisture inside pressure gauge | Clean and improve waterproof sealing |

| Missing calibration label | Replace calibration label |

| Missing cable tray cover | Install tray cover |

| Missing grounding jumper | Install grounding jumper |

| Loose cable gland wiring | Re-tighten wiring |

| Impulse line leakage | Re-seal and tighten fittings |

| Capillary tube not properly fixed | Coil and secure capillary tube |

| Excessive vibration | Install clamps or supports |

| Non-explosion-proof plug used | Replace with certified Ex-proof plug |

| Grounding shared by multiple instruments | Modify to single-point grounding |