I. Daily Inspection Guidelines

Inspections should combine visual, auditory, tactile, and measurement methods to ensure the system is functioning optimally.

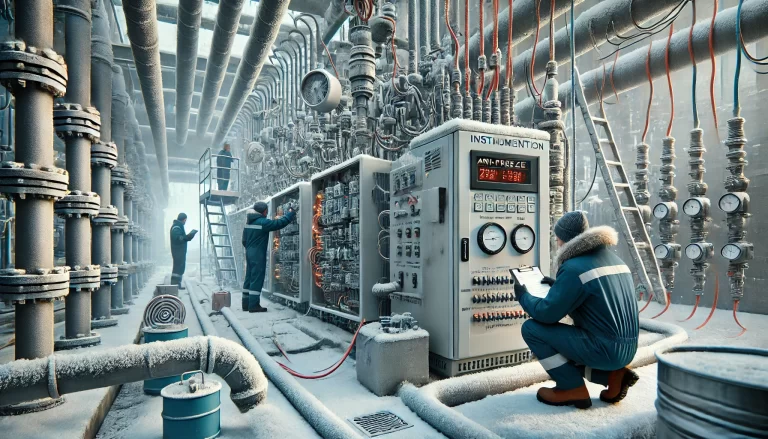

1. Visual Inspection

Steam Supply and Condensate Drainage: Check if the pressure in the main steam line and steam headers falls within the normal range (typically 0.3~0.8MPa). Observe the condensate drain for proper discharge of steam or water.

Insulation Condition: Inspect the insulation for any signs of damage, cracking, peeling, or corrosion.

Heat Trace Connections: Ensure there are no signs of steam leakage at flanges, valves, or connection points.

Condensate Recovery System: Check the level and temperature in the condensate recovery tank, and ensure the recovery lines are unobstructed.

Steam Trap Status:

Normal: Intermittent white steam discharge.

Internal Leakage: Continuous steam discharge.

Blocked: No discharge, no drainage, and the line remains cold.

2. Auditory Inspection

Steam Trap Sounds: A normally operating steam trap should emit rhythmic “clicking” sounds or intermittent drainage noises.

Steam Flow Noise: Use a stethoscope or screwdriver to listen for the characteristic “hissing” sound, indicating unobstructed steam flow.

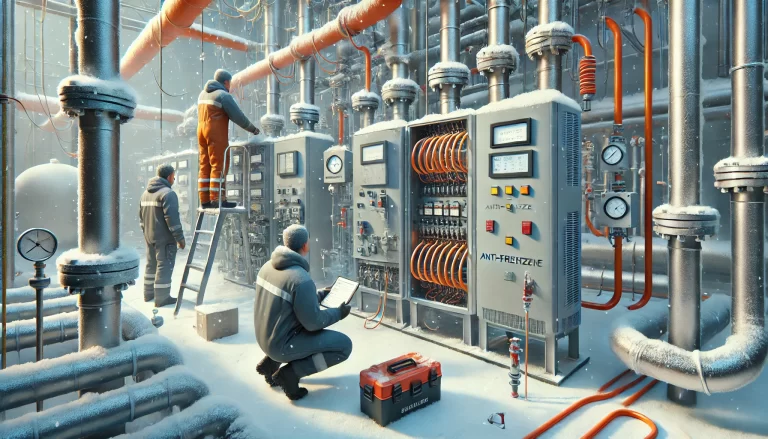

3. Tactile Inspection

Temperature Gradients: Starting from the steam supply, check the heat trace lines to ensure the temperature is uniform.

Key Areas: Focus on measuring points, valve groups, and transmitters that are prone to freezing.

“Dead Zones” Check: Feel the ends of heat tracing pipes or U-bends to ensure they are warm and free of condensate buildup.

4. Measurement Tools

Use of Infrared Thermometers: Regularly check the critical points of instruments and heat trace lines with an infrared thermometer.

Process Parameter Verification: Ensure that all instruments are showing normal readings.

II. Maintenance and Care Guidelines

1. Pre-Season Start-Up

System Check: Conduct a comprehensive inspection of the entire steam tracing system before starting it up.

Steam Trap Maintenance: Clean the steam trap’s filters, test its operation, and replace or clean internal components if necessary.

Condensate Drainage: Slightly open the bypass valve or low-point drain valve to expel any air, rust, or accumulated sludge.

2. During Operation

Regular Steam Trap Testing: Establish a record for regular inspections of the steam traps, checking their operation every week or bi-weekly.

Maintain Insulation Integrity: Any damage to the insulation should be promptly repaired.

Prevent External Damage: Avoid placing heavy items or performing physical work near the heat tracing lines.

3. Post-Season Shutdown

Thorough Blowing: Close the main steam valve and open all low-point drain valves. Use instrument air or nitrogen to blow out the entire system.

Isolation and Marking: Shut the valves on all branch lines and hang a “Out of Service” sign for safety.

Record and Analyze: Document any issues encountered during the season to inform maintenance plans for the next year.

III. Steam Tracing Repair Procedures

Core Principle: Always isolate, depressurize, and cool down before beginning any maintenance. Prevent burns at all costs.

Step-by-Step Guide:

1. Preparation

Work Permit: Ensure that proper work permits are issued for tasks such as hot work or general maintenance.

Technical Briefing: Ensure all team members are clear on the scope of work, location, risks, and safety measures.

Tool Preparation: Gather the necessary wrenches, pipe wrenches, new steam traps, seals, insulation materials, and personal protective equipment (PPE).

2. Safety Isolation and Depressurization

Shut the Steam Valve: Turn off the steam supply valve for the heat tracing line being repaired, and hang a “Do Not Operate, Work in Progress” warning sign.

Open Condensate Drain Valves: Slowly open all low-point condensate drain valves and steam trap bypass valves to release pressure and water.

Confirm Zero Pressure: Ensure the system is depressurized by checking pressure gauges, touching pipes, and listening for any sounds of residual steam.

Allow the System to Cool: Let the system cool down until it reaches a safe temperature for working.

3. Repair Process

Replace Steam Traps:

Remove the old steam trap, ensuring you note the installation direction.

Clean the interface threads or flange faces on both sides.

Install a new steam trap with adequate sealant or gaskets, ensuring it is tightened properly.

Fix Leak Points:

If a threaded connection is leaking, tighten the fitting.

For leaks in the heat tracing pipe itself, cut out the damaged section and connect it with a straight coupling.

Replace Heat Tracing Pipe:

Remove the old pipe, and lay down new piping, ensuring proper alignment and secure fixing.

4. Post-Repair Restoration and Testing

Close Drain Valves: After repairs are completed, close all drain and bypass valves.

Slow System Start-Up: Slowly open the isolation valve and begin warming the repaired section of the pipe.

Leak Check: Carefully inspect all connections and fittings for leaks.

System Verification: Once the system is up to temperature, check the performance of the steam traps and the instrument temperatures.

Restore Insulation: Replace the insulation to its original state once everything is confirmed to be working.

Key Safety Considerations:

Burn Prevention: Steam and condensate can reach extremely high temperatures, so ensure that insulated gloves, long-sleeve work clothes, safety helmets, and goggles are worn.

Freeze Protection: If working in low-temperature environments, provide temporary insulation for isolated instrument lines during maintenance.

Avoid Water Hammer: Gradually heat up pipes when reintroducing steam to avoid damaging the system.

Environmental Responsibility: Steam and condensate are valuable resources. Avoid unnecessary discharges and waste.