1. Introduction

In the design and operation of chemical installations, the choice of instrumentation is not only related to production efficiency but also to intrinsic safety. In hazardous areas such as Zone 2, the explosion protection type of field instruments becomes a key decision.

This article compares Intrinsically Safe (IS) and Explosion-Proof (Ex-d) instruments from the perspectives of compliance, cost, installation, maintenance, limitations, and applicability, helping engineers and project managers make informed decisions.

2. Compliance and Safety

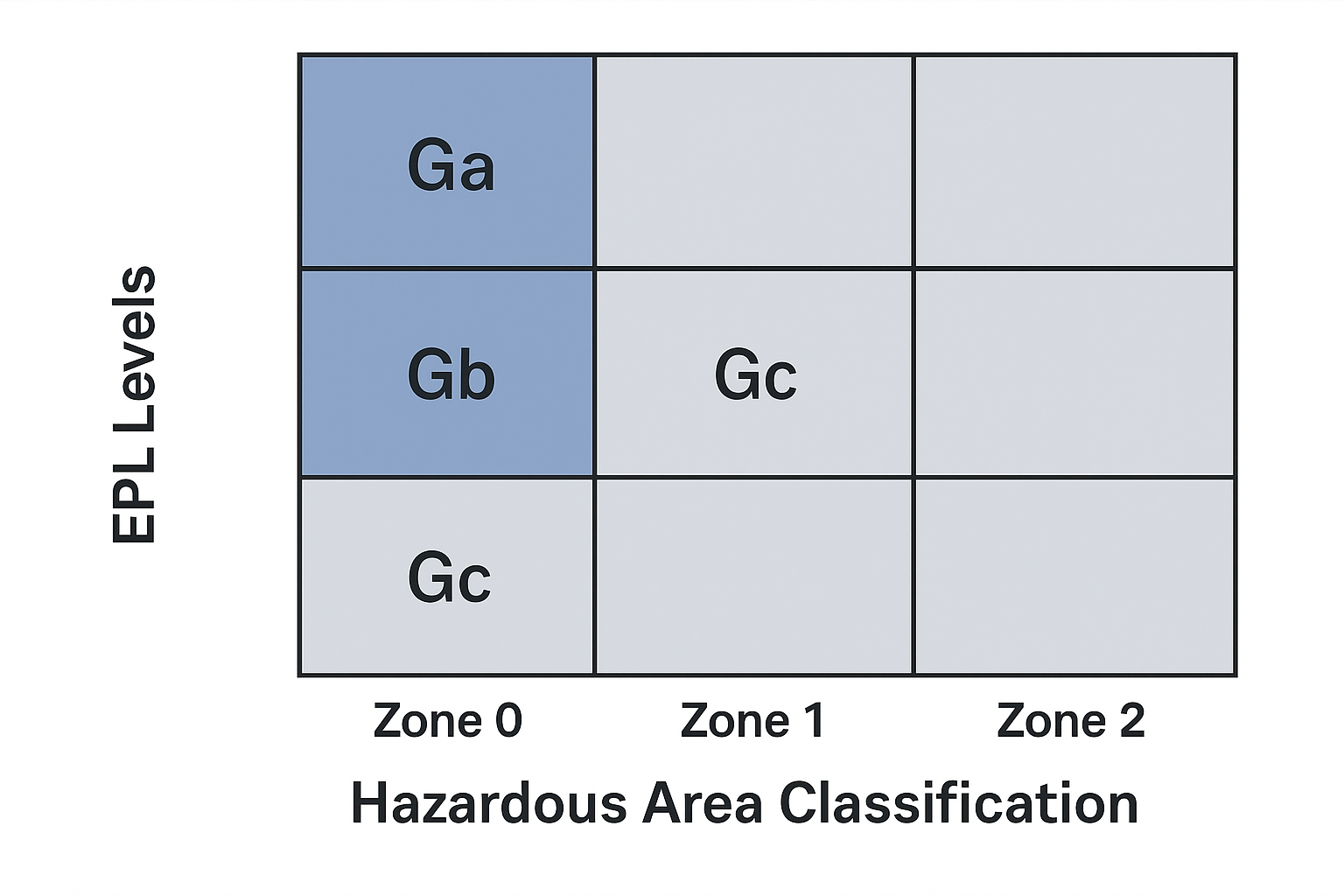

According to GB 50058-2014 — Code for Design of Electrical Installations in Explosive Hazardous Environments:

Zone 2: Explosive gas mixtures are unlikely to occur during normal operation.

Equipment Protection Level (EPL): Minimum requirement is Gc.

Replacement principle: Higher EPL may substitute for lower, and different explosion-proof types can be interchanged at the same EPL.

👉 Both IS and Ex-d instruments meet regulatory and safety requirements.

IS instruments: Typically certified at Gc level.

Ex-d instruments: Generally certified at Gb level, providing higher redundancy than required for Zone 2.

3. Cost Comparison

3.1 Typical System Configurations

Intrinsic Safety (IS) System

IS instrument + IS cable + junction box + isolator cabinet + control system

Explosion-Proof (Ex-d) System

Ex-d instrument + standard cable + junction box + control system

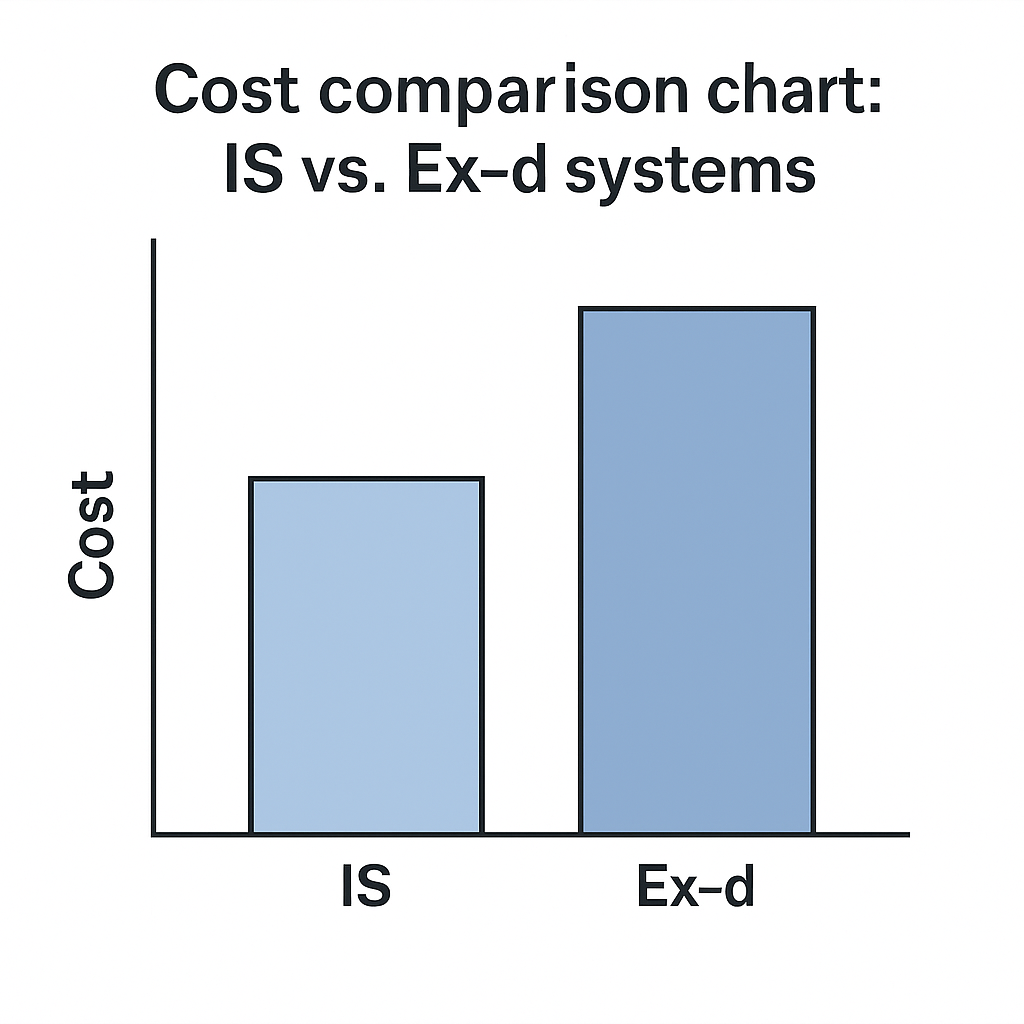

3.2 Cost Factors

Instrument price: Generally similar, only slight differences.

Cables: IS cables are slightly more expensive (0.2–0.3 RMB/m).

Isolators: Required in IS systems, costing 200–400 RMB per channel, also consuming cabinet space.

Grounding: Ex-d instruments must be reliably grounded, while IS instruments may not require individual grounding.

Cable trays: IS cables must be routed separately, increasing space and installation cost.

👉 Overall, IS systems are slightly more expensive than Ex-d systems, though in optimized designs the difference can be minimized.

4. Installation and Maintenance

4.1 Field Instrument Maintenance

IS instruments: Allow cover opening under live conditions due to energy limitation → flexible and safe for on-site repair.

Ex-d instruments: Cover opening under live conditions is prohibited; special safety measures required if live intervention is needed.

4.2 Cabinet and Loop Maintenance

IS systems: More isolators increase maintenance workload.

Ex-d systems: Simpler loop structure, aligned with GB 50770’s principle of “minimizing intermediate stages in safety instrumented systems.”

5. Limitations of Intrinsic Safety

IS is not a universal solution:

Not suitable for high-power loads or certain four-wire instruments.

Actuators (e.g., solenoid valves) may respond slowly due to energy limits.

Mixed use of IS and Ex-d instruments in one project increases wiring complexity.

👉 Best suited for AI/AO/DI/DO signal instruments, while Ex-d remains more practical for power-demanding devices.

6. Impact on Cabling

IS systems require additional space for isolators in cabinets.

Cables for IS loops must be routed separately or shielded, increasing installation complexity.

Retrofit or expansion projects may face higher costs due to these requirements.

7. Selection Guidance

Compliance: Both solutions meet Zone 2 safety requirements.

Cost: Comparable, IS usually higher.

Maintenance: IS more flexible in the field; Ex-d simpler at the system level.

Applicability: Ex-d more versatile; IS advantageous in low-power signal circuits.

👉 Recommendation: For chemical plant Zone 2 installations, Explosion-Proof (Ex-d) instruments are generally preferred due to their wide applicability and simpler loops. Intrinsically Safe (IS) instruments remain a valuable supplement in specific signal circuits.

8. Final Thoughts

There is no “one-size-fits-all” solution for instrument selection in hazardous areas. The final decision should be based on corporate standards, project conditions, supply chain availability, and installation requirements. A balanced approach ensures compliance, economic efficiency, and operational practicality.