Abstract

Pipeline purging is widely recognized as a critical operation to ensure the cleanliness and reliability of gas pipelines. However, instrument purging is equally important for the stable and accurate performance of industrial automation systems. This article explains the necessity, procedures, common challenges, and system-wide impact of instrument purging, providing guidance for standardized operation in chemical, energy, oil, and gas industries.

1. Necessity of Instrument Purging

Instruments such as level transmitters, flowmeters, pressure sensors, temperature sensors, and gas analyzers play a decisive role in process monitoring and control. Without regular purging, impurities may compromise their accuracy and reliability.

Preventing contamination of measuring elements

Residual particles (e.g., welding slag, rust) may block or damage sensitive components, causing deviations or failure.

Example: Particles blocking flowmeter channels or damaging pressure diaphragms.Avoiding jamming or failure

Moving parts such as valves or regulators may seize due to solid impurities, leading to operational difficulties or breakdown.Ensuring long-term stability

Periodic purging reduces measurement drift, prevents failures, and supports continuous safe operation.

Table 1 — Typical Impurities vs. Impact on Instruments

| Type of Impurity | Typical Source | Impact on Instruments |

|---|---|---|

| Welding slag | Pipe welding and installation residues | Blocks flow channels, damages pressure diaphragms, causes signal drift |

| Rust/oxide particles | Corrosion inside pipes and tanks | Erodes sensor surfaces, reduces sensitivity, causes inaccurate measurement |

| Dust and fine solids | Air/gas streams, environmental contamination | Deposits on sensor probes, increases response time, leads to calibration deviation |

| Oil/grease residues | Lubrication, sealing materials | Forms insulating film on temperature/level probes, affecting heat transfer and signal output |

| Moisture/condensate | Humid air, steam, or unsealed connections | Causes short circuits, sensor corrosion, unstable electronic signals |

| Chemical residues | Process fluids or cleaning agents | Corrodes sensitive components, alters sensor surface properties, reduces lifespan |

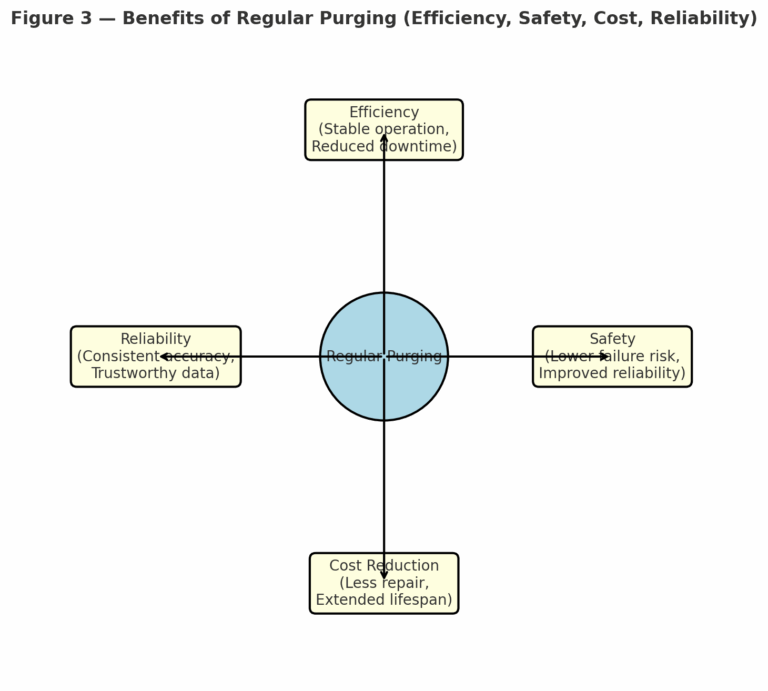

2. Standard Procedure for Instrument Purging

Instrument purging should follow strict operational steps, similar to pipeline purging but with additional protection for sensitive devices.

Identify the target instrument

Select the instruments requiring purging (level, flow, pressure, temperature, or analyzers).Close isolation valves

Protect instruments from direct high-pressure impact during purging.Connect purge gas source

Typically compressed air or nitrogen. Adjust pressure and flow according to instrument specifications.Execute purging

Gradually increase flow to flush internal passages.

For critical ports, use dedicated purge connections.Verify effectiveness

Perform visual checks or use specialized cleaning tools to confirm no residue remains.Restore instrument operation

Re-open isolation valves, conduct functional tests, and recalibrate if necessary.Record and report

Document purge pressure, duration, and inspection results. Update maintenance logs for traceability.

3. Common Problems in Instrument Purging

Excessive or insufficient purge flow

Too high: may damage sensors.

Too low: ineffective cleaning.

✅ Solution: follow OEM specifications.

Persistent blockages

Severe clogging may require instrument disassembly and mechanical cleaning.Improper purging practices

Risk of pushing impurities deeper into the device. Requires operator training.Residual damage

Instruments may already be compromised by long-term deposits; timely replacement is necessary.

Table 2 — Typical Fault Causes vs. Preventive Measures

| Fault Cause | Typical Scenario | Preventive Measure |

|---|---|---|

| Excessive purge flow | Gas pressure too high during purging | Adjust purge pressure/flow according to instrument specification; use flow regulators |

| Insufficient purge flow | Low purge rate, ineffective debris removal | Verify flowrate before operation; ensure adequate purge duration |

| Residual blockages (severe fouling) | Heavy deposits, welding slag, hardened particles | Perform instrument disassembly and mechanical cleaning when normal purge is ineffective |

| Improper purging practices | Incorrect valve sequence or direct jet to sensors | Train operators; follow SOP strictly; use isolation valves properly |

| Contaminants entering instruments | Backflow of impurities during purging | Install check valves or filters; purge from correct direction |

| Long-term contamination damage | Deposits accumulated over years causing corrosion or drift | Implement regular preventive purging schedule; replace aged instruments in time |

| Moisture ingress during purging | Use of unconditioned air with high humidity | Use dry compressed air or nitrogen as purge gas; install dryers/filters |

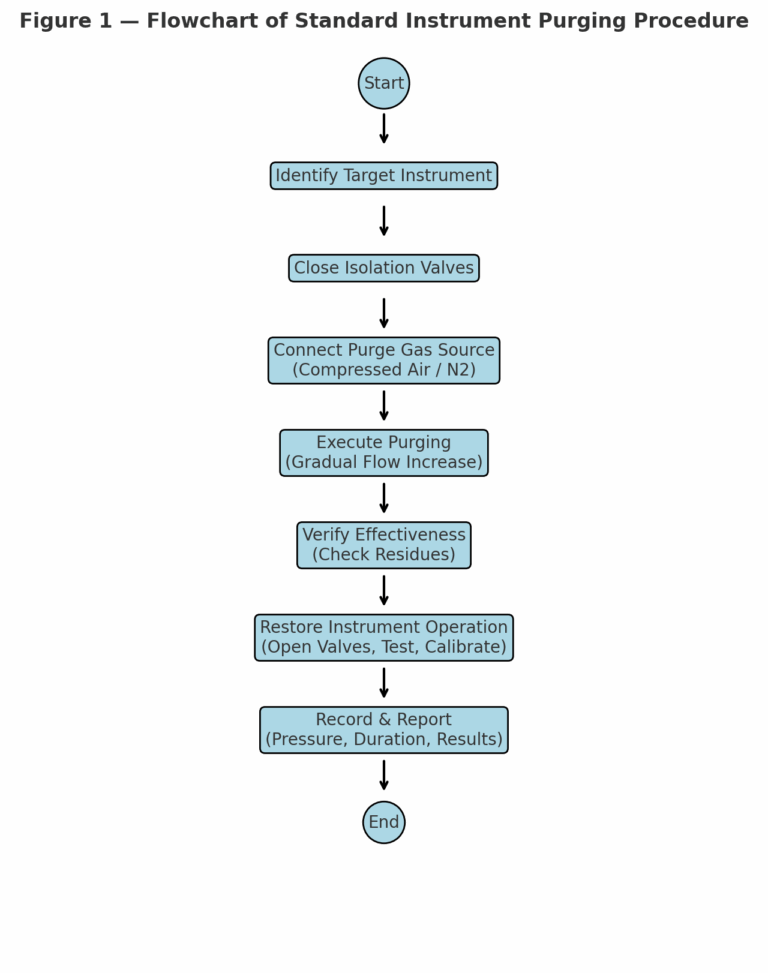

4. Synergy Between Pipeline and Instrument Purging

Pipeline purging and instrument purging are interdependent:

Pipeline residues can migrate into instrument chambers, reducing accuracy.

Instrument malfunctions can in turn disrupt pipeline monitoring and control.

Therefore, both operations should be performed simultaneously during installation, commissioning, or maintenance.

Example: Gas pipeline impurities affecting a flowmeter or damaging a pressure sensor.

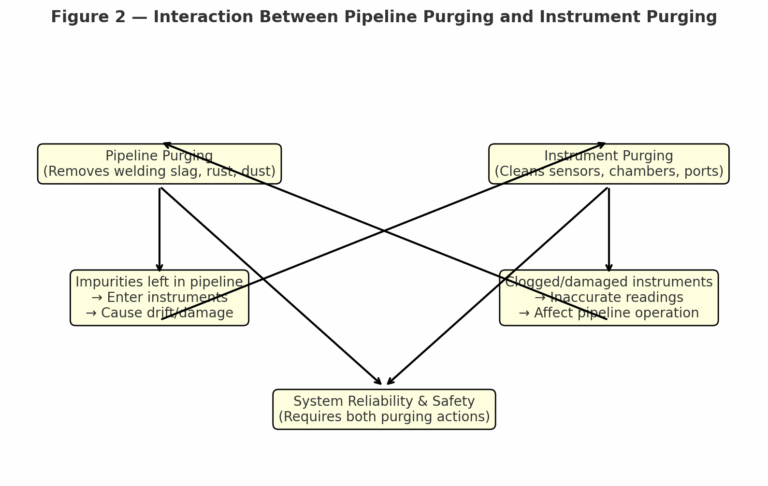

5. Conclusion

Both pipeline purging and instrument purging are indispensable for stable and safe industrial operations. By establishing standardized purging practices, companies can:

Reduce measurement errors

Extend equipment lifespan

Lower unplanned downtime

Improve system safety and efficiency

To achieve this, enterprises should implement:

Strict purging procedures

Operator training programs

Maintenance records and traceability systems