Abstract

Instrument lifecycle management is a systematic and digitalized approach that treats the entire process of an instrument—from design to disposal—as one integrated chain. By connecting data and ensuring collaborative management across each stage, organizations can achieve safety, reliability, cost efficiency, and regulatory compliance.

1. Lifecycle Stages of Industrial Instruments

1.1 Design & Selection

Requirement Analysis: Define instrument type, accuracy, range, and functions based on process or research needs.

Evaluation: Consider performance, reliability, durability, compatibility, supplier reputation, and technical support.

1.2 Procurement & Acceptance

Supplier Selection: Choose reliable suppliers with strong technical and quality assurance capabilities.

Acceptance Testing: Joint inspections by users, supervisors, and suppliers to verify model, specifications, accessories, and conduct performance checks.

1.3 Installation & Commissioning

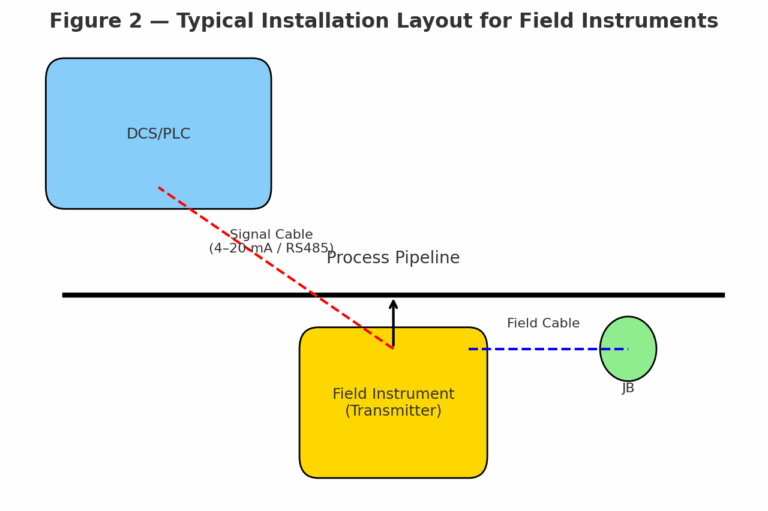

Installation Standards: Follow manuals and industry standards; ensure proper environmental conditions (temperature, humidity, vibration).

Calibration & Commissioning: Adjust and calibrate instruments to optimal operating condition; verify measurement accuracy.

1.4 Operation & Maintenance

Asset Register: Maintain a detailed ledger with purchase date, model, location, maintenance history, and calibration records.

Routine Inspection: Scheduled checks to detect abnormal conditions early.

Periodic Maintenance: Cleaning, lubrication, replacement of consumables, based on service frequency and environment.

Calibration & Verification: Regular calibration to maintain accuracy and compliance.

Fault Handling: Establish rapid response mechanisms; analyze root causes; document corrective actions.

1.5 Decommissioning & Disposal

Assessment: Technical evaluation to determine if an instrument has reached end-of-life or cannot be repaired.

Compliance Disposal: Follow environmental and safety regulations to ensure proper disposal.

2. Key Enabling Technologies

Industrial Internet Identification System: Assign a unique “digital ID” to each instrument for traceability across all lifecycle stages.

Information Management Systems: Use digital platforms to standardize data models, eliminate data silos, and improve decision-making.

Predictive Maintenance: Monitor key parameters in real time, apply algorithms to predict degradation trends, and dynamically adjust maintenance plans.

3. Benefits of Lifecycle Management

Improved Reliability: Early detection and elimination of hidden risks reduce failures.

Cost Reduction: Optimized maintenance strategies minimize unplanned downtime and unnecessary repairs.

Enhanced Safety: Ensures stable and accurate operation in critical applications such as hazardous media measurement.

Efficiency Gains: Digital management reduces manual intervention, improves collaboration, and accelerates decision-making.

4. Practical Recommendations for Implementation

Start with Data: Build an instrument asset register and standardize documentation.

Phased Deployment: Implement lifecycle management step by step (e.g., begin with calibration tracking, then extend to predictive maintenance).

Collaborative Ecosystem: Involve manufacturers, calibration labs, and management authorities in data sharing.

Compliance Focus: Ensure EHS (Environment, Health, Safety) standards are integrated into decommissioning.

Conclusion

Instrument lifecycle management is not only a technical upgrade but also a shift in management philosophy. Through digitalization and predictive strategies, enterprises can enhance reliability, reduce costs, improve safety, and boost efficiency—ultimately supporting sustainable industrial development.