The monthly report should focus on five key dimensions:

Work Achievements – Problem Analysis – Risk & Solution – Capability Improvement – Next Month Plan.

All sections should contain measurable data, clear outcomes, and traceable actions. The goal is to present both value creation and problem-solving capabilities.

1. Major Work Achievements This Month

(Quantified results + relevance to production)

Describe your work using the logic:

Specific task → Execution process → Quantitative results → Value to production.

1.1 Instrument Maintenance & Overhaul (Core Function)

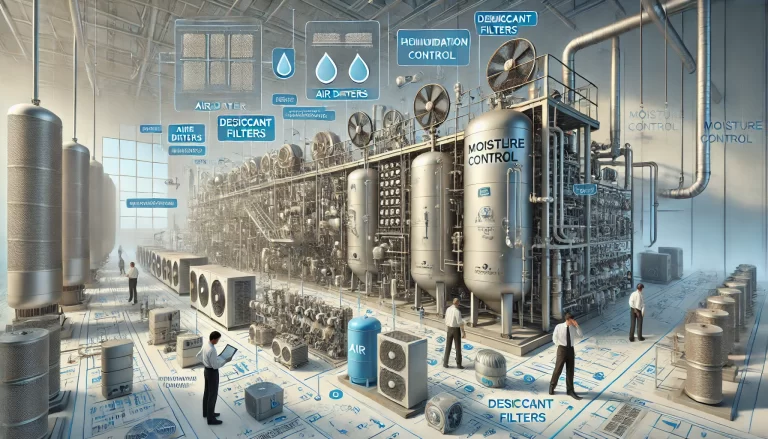

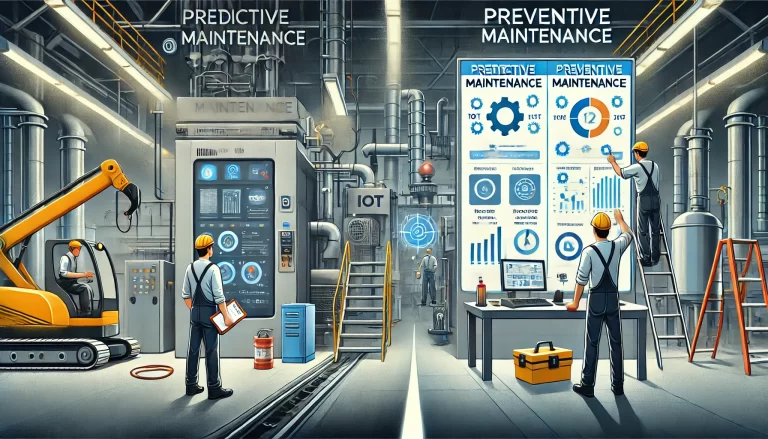

Routine Inspection & Preventive Maintenance:

Completed monthly inspection of XX instruments across XX workshops (e.g., reactor area, tank farm, utilities).

Covered four major categories: pressure, temperature, level, and flow.

Detected and resolved XX minor faults on site, e.g.:Replaced 2 damaged temperature sensors in the cooling water system.

Tightened 3 loose terminals on pressure transmitters in the solvent tank area.

Conducted preventive maintenance on XX key instruments, such as cleaning differential pressure level transmitters or reapplying coupling gel for ultrasonic flowmeters.

→ Instrument uptime rate: XX% (target XX%, Δ vs last month: +/–XX%).

Breakdown & Emergency Repair:

Responded to XX instrument failures, average troubleshooting time XX minutes (target XX min), no production interruptions.

Example cases:On XX date/time, the flowmeter of Distillation Tower #1 showed no signal; found electrodes blocked by polymer, cleaned and restored within 45 minutes.

On XX date/time, combustible gas detector false alarm occurred due to humidity; replaced with moisture-proof sensor, eliminating false triggering risk.

Calibration & Verification:

Completed calibration of XX instruments (e.g., 12 pressure transmitters, 8 turbine flowmeters).

XX units qualified, XX out of tolerance (e.g., 2 vortex flowmeters showed 0.8% deviation and re-calibrated successfully).

Coordinated with metrology institute to complete compulsory verification for XX custody-transfer instruments, all passed in compliance with JJG 1037-2008 standards.

1.2 Instrument Modification & Project Implementation (Value-Added Function)

If there was a modification project:

Promoted the XX Workshop Instrument Upgrade Project, completing XX stage this month.

Installed XX new instruments (e.g., 20 wireless temperature transmitters).

Current progress XX% (planned XX%), total man-hours XX h.

Test data after commissioning show:Transmission delay reduced from XXs → XXs.

Alarm response improved by XX%, enhancing process optimization.

If no new project:

Participated in the Process Optimization Program for XX section (e.g., reactor heating).

Proposed adding redundant temperature transmitters (1 working + 1 standby).

Data analysis from past 3 months led to optimized heating rate from 5°C/h → 3°C/h, improving product yield by XX%.

1.3 Safety & Compliance Management (Baseline Function)

Safety Inspection & Hazard Correction:

Joined monthly plant safety audit focusing on explosion-proof zones (solvent area, gasification unit).

Found XX issues, e.g.:One aged explosion-proof gland;

Two unsealed instrument cable entries.

Implemented corrective actions: replaced fittings, sealed with explosion-proof clay.

Remaining XX items scheduled by XX date to ensure compliance with Ex d IIB T4 rating.

Emergency Response Preparedness:

Updated Instrument Failure Emergency Plan, adding two new scenarios:“Smart instrument communication failure”

“Interlock false triggering.”

Conducted XX emergency drills (e.g., “Level gauge no display”), XX participants, average response time XX min, improved by XX% vs last month.

2. Problems & Root Cause Analysis

(Specific + In-depth)

Avoid vague descriptions. Analyze root causes from the five dimensions: Man – Machine – Material – Method – Environment.

High Instrument Failure Rate:

Flowmeter failure in polymerization unit twice this month due to high-viscosity media clogging sensors.

Root causes:Medium viscosity 200 cP vs design 100 cP → undersized sensor bore.

Inadequate cleaning frequency (once per month vs required every 2 weeks).

Low Calibration Efficiency:

Total calibration time exceeded plan by XX hours.

Causes:Old standard pressure source caused unstable pressure.

New technicians unfamiliar with wireless instrument calibration, reducing single-person efficiency by ~30%.

Cross-Department Coordination Delay:

In Tank Area Upgrade Project, modification delayed 5% due to lack of synchronized downtime schedule with process team.

Causes:Communication initiated only 3 days before work.

No joint scheduling mechanism between instrument and production teams.

3. Corrective Actions & Follow-Up Status

(Actionable + Verifiable)

Each issue should have specific actions, responsible persons, timeline, and verification results.

Address High-Viscosity Flowmeter Blockage:

Ordered customized anti-clogging sensors (DN80 instead of DN50), ETA XX date, replacement within 3 days after arrival.

Issued Maintenance Plan for High-Viscosity Instruments: cleaning every 2 weeks, technician XX responsible, record residue after each cleaning for traceability.

Improve Calibration Efficiency:

Submitted request for new 0.02-grade intelligent pressure calibrator, expected XX month.

Conducted Smart Instrument Calibration Training for new staff; each must pass practical test (≤±0.5% deviation).

XX staff completed, XX pending by XX date.

Enhance Cross-Department Coordination:

Established “Instrument Work–Production Schedule” pre-notice mechanism (7 days advance notice required).

Weekly coordination meeting with Process & Equipment Departments (every Wednesday afternoon).

Two meetings held this month; response time for schedule conflicts reduced to <24 hours.

4. Skills Development & Experience Summary

(Individual + Team Level)

4.1 Technical Skills:

Studied LoRa wireless communication protocols, resolved 3 wireless transmitter communication failures by interference analysis.

Compiled first draft of Smart Instrument Troubleshooting Handbook with 15 common fault cases shared within team.

4.2 Management & Data Discipline:

Optimized Instrument Maintenance Database by adding “Instrument Health Index” (graded A/B/C based on failure rate, calibration score, and service years).

Identified XX C-grade instruments (<60 score), prioritized replacement to improve reliability.

4.3 Teamwork & Coordination:

Established “3C Collaboration Principle”: Communicate early, Coordinate frequently, Close problems quickly.

In practice: submit downtime request 7 days ahead, update progress daily, resolve conflicts immediately via group chat.

5. Work Plan for Next Month

(Quantified + Linked to Annual Targets)

Maintenance & Calibration:

Complete monthly inspection of XX instruments in XX area, ensure uptime ≥99.5%.

Calibrate XX instruments (e.g., 8 electromagnetic flowmeters, 6 pressure transmitters) with ≥98% pass rate.

Commission new pressure calibrator and improve calibration efficiency by 20%.

Rectification & Project Progress:

Replace 2 clogged flow sensors in polymer unit, monitor for zero failures in following month.

Advance XX Upgrade Project to XX% completion, confirm downtime window XX–XX dates, submit request 7 days prior.

Safety & Capability Building:

Complete XX pending safety corrections.

Conduct one Explosion-Proof Instrument Maintenance Training covering all technicians.

Finalize and release Troubleshooting Handbook v1.0 (add 5 new fault cases).

Cross-Department Optimization:

Hold weekly coordination meetings (every Wednesday).

Confirm XX shutdown tasks in advance.

Coordinate with Purchasing to ensure delivery of XX anti-clogging sensors by XX date.

End of Report

Prepared by: ____________________

Position: Instrument Engineer

Date: ___________________________

Department: _____________________