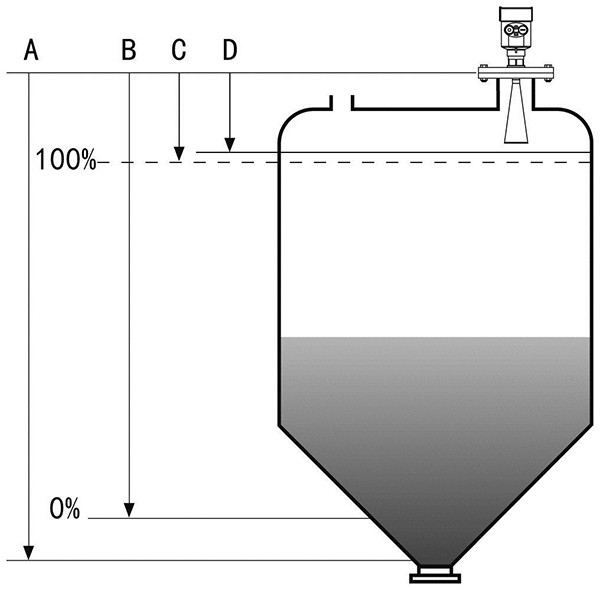

Radar level meter adopts the working mode of transmitting, reflecting, and receiving. The antenna of the radar level meter emits electromagnetic waves, which are reflected by the surface of the object to be measured and then received by the antenna.

The time from transmitting to receiving is proportional to the distance to the liquid surface. The radar level meter records the time experienced by the pulse wave, while the transmission speed of the electromagnetic wave is constant, so the distance from the liquid surface to the radar antenna can be calculated to know the level of the liquid surface.

In practical application, radar level meter has two types: FM continuous wave type and pulse wave type. The level meter using FM continuous wave technology consumes a lot of power, must use a four-wire system, and has a complicated electronic circuit.

The level meter with radar pulse wave technology has low power consumption and can be powered by 24VDC in a two-wire system, which is easy to realize intrinsic safety. High accuracy and wider application range.

The above article explains the selection problem, after the selection is completed, we must consider the installation problem, that is, how to install the waveguide on the large floating roof tank. The current large floating roof crude oil storage tank is located on both sides of the tank with two guide pillar auxiliary floating plates with the liquid level up and down.

Therefore, the operator can measure the level manually by mechanical means through the guide pillars. If we install another guide tube on the floating plate to detect the liquid level, it is equivalent to installing another guide column for the floating plate, which may cause the floating plate to be stuck and unable to float up and down. In this situation, it is only feasible to do something on the guide column.

Take a crude oil reserve as an example, 10×10⁴m³ storage tank uses two DN400 guide columns. The technicians decided to install a DN200 wave guide tube in one of the guide columns. This solved the installation problem of radar level, while the other guidepost could still play the role of manual oil measurement. In addition, the selection of the supply voltage also needs attention. For large crude oil storage depots, the storage area is largely due to the large diameter of the tanks.

Take crude oil storage as an example, although a control center and remote control unit are set up, the instrument signals in the storage area are connected to the control center and remote control nearby. However, there are still many instrumentation signal cables longer than 1Km, and the line voltage drop is large.

The actual usage shows that 24V DC power is not enough to drive the radar level meter at such a long distance, leading to various problems with the radar level meter. Therefore, a 220VAC-powered radar level meter must be selected.