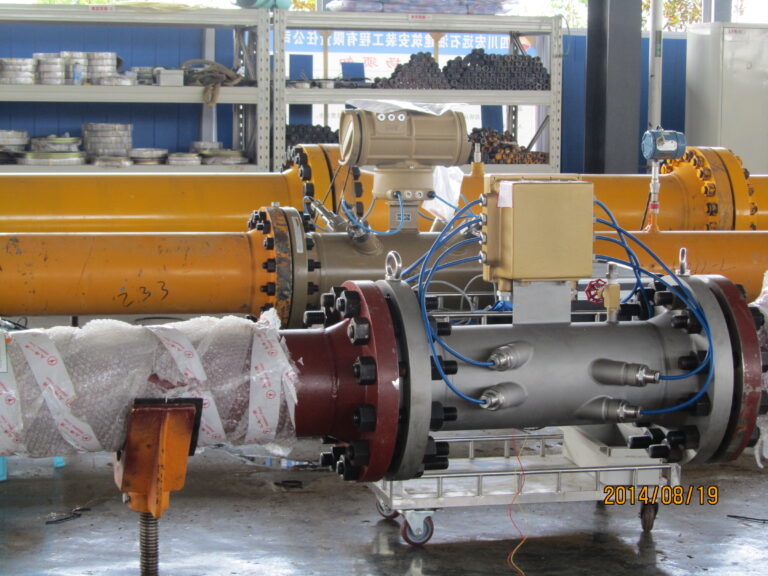

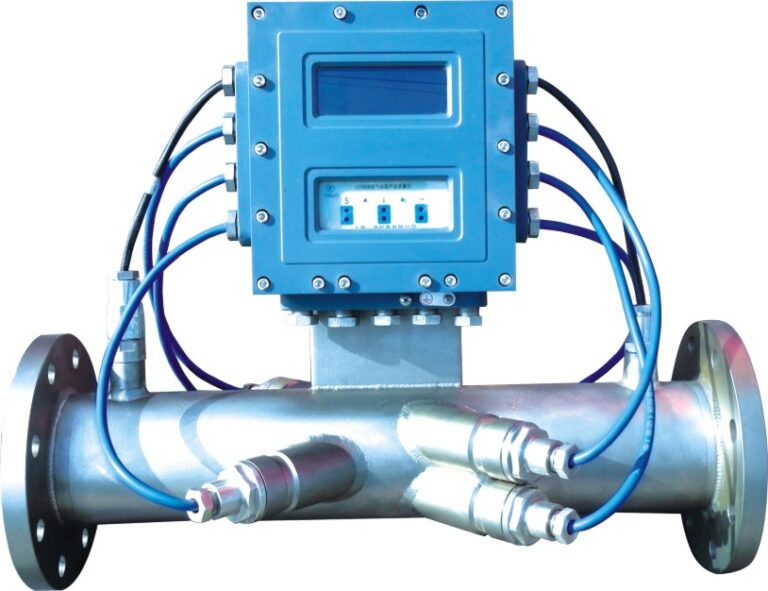

Ultrasonic flow meters are widely used for measuring the flow rate of liquids and gases in various industries. They work by sending ultrasonic sound waves through the fluid, either in a direct or diagonal path, and measuring the time it takes for the sound waves to travel. The difference in travel time (in transit-time ultrasonic meters) or changes in sound frequency (in Doppler ultrasonic meters) is used to calculate the flow rate. Ultrasonic flow meters are non-intrusive, accurate, and suitable for applications where cleanliness or minimal pressure drop is required. However, achieving accurate measurements depends on proper installation, including straight pipe lengths to ensure stable flow profiles and minimize disturbances.

Below are the essential installation requirements and considerations for ultrasonic flow meters, including recommended straight pipe lengths and best practices for reliable measurements.

1. Why Straight Pipe Sections Are Important for Ultrasonic Flow Meters

Ultrasonic flow meters rely on a stable, symmetrical flow profile to ensure that sound waves travel through the fluid without interference. Upstream disturbances like elbows, valves, and pumps can cause turbulence, swirl, or asymmetrical flow, which disrupts the accuracy of the ultrasonic readings. Straight pipe sections before and after the ultrasonic flow meter help the fluid stabilize, creating a uniform flow profile that allows for consistent and accurate readings.

2. Upstream Straight Pipe Requirements

The upstream (inlet) straight pipe section is critical in ensuring that the flow profile is fully developed and free of disturbances when it reaches the ultrasonic meter. The required length varies depending on the degree of upstream disturbance:

- Basic Requirement: For installations without significant upstream disturbances, a minimum of 10 times the pipe diameter (10D) is recommended as the upstream straight pipe section.

- Significant Upstream Disturbances: In cases with multiple upstream disturbances (such as elbows or control valves), the upstream straight section should be extended to 15D or even 20D for highly turbulent conditions, allowing the flow to stabilize before reaching the ultrasonic meter.

3. Downstream Straight Pipe Requirements

The downstream (outlet) straight pipe section is generally less critical but still necessary for stabilizing the flow profile after the ultrasonic meter:

- Basic Requirement: A minimum of 5 times the pipe diameter (5D) is generally recommended as the downstream straight pipe section.

- Higher Precision Requirement: For applications requiring high precision or where additional downstream disturbances exist, extending the downstream section to 10D can help maintain measurement accuracy.

4. Installation Reference Table

The following table summarizes recommended straight pipe lengths based on common upstream disturbances for ultrasonic flow meters:

| Upstream Disturbance Type | Recommended Upstream Straight Pipe Length | Recommended Downstream Straight Pipe Length |

|---|---|---|

| No Disturbance | 10D | 5D |

| Single 90° Elbow | 15D | 5D |

| Two 90° Elbows (Same Plane) | 15D | 5D |

| Two 90° Elbows (Different Planes) | 20D | 5D |

| Reducer or Expander | 15D | 5D |

| Valve (Control or Throttle) | 20D | 5D to 10D |

| Pumps or Compressors (High Turbulence) | 25D | 10D |

| Flow Conditioner Installed | 5D | 5D |

Notes:

- D represents the inner diameter of the pipe.

- Upstream Length Variability: The upstream length varies based on the type and severity of the upstream disturbance.

- Downstream Length: Generally shorter but may need extension to 10D in high-accuracy applications or where significant downstream disturbances are present.

5. Additional Considerations for Accurate Measurements

In addition to straight pipe sections, other factors can significantly impact the accuracy of ultrasonic flow meters:

- Installation Position: Ultrasonic flow meters are generally installed in a horizontal pipe, ideally in the middle third of the pipe to avoid effects of flow disturbances along the walls. For vertical installations, the flow direction should be upward to ensure full pipe flow and avoid air pockets.

- Full Pipe Flow: Ultrasonic flow meters require the pipe to be completely full of fluid for accurate readings. For applications where this might be a concern (e.g., partially full pipes), installing the meter in a location where full pipe flow is guaranteed is essential.

- Pipe Material and Wall Thickness: Pipe material can affect the travel of ultrasonic signals. Most ultrasonic meters are compatible with materials like steel, stainless steel, PVC, and copper. The pipe wall thickness should be within the limits specified by the meter manufacturer.

- Flow Conditioners: In cases where space is limited, flow conditioners or straightening vanes can help create a more uniform flow profile, minimizing the need for long straight sections.

6. Types of Ultrasonic Flow Meters and Specific Considerations

Different types of ultrasonic flow meters may have unique installation considerations:

- Transit-Time Ultrasonic Meters: These meters are highly sensitive to flow profile and require stable, fully developed flow. They are best suited for clean fluids and typically need more straight pipe length than Doppler meters.

- Doppler Ultrasonic Meters: Doppler meters are generally used for dirty or aerated fluids and are slightly less sensitive to flow profile than transit-time meters. However, they still benefit from straight pipe sections for optimal performance.

- Clamp-On Ultrasonic Meters: These meters are mounted externally on the pipe and rely on stable flow conditions. They typically follow the same straight pipe recommendations as inline ultrasonic meters but may require additional adjustments based on pipe wall thickness and material.

7. Importance of Following Manufacturer and Industry Standards

Each ultrasonic flow meter may have specific installation guidelines provided by the manufacturer, including recommended straight pipe lengths, which are designed to achieve optimal accuracy. Following these manufacturer guidelines, along with relevant industry standards (such as ISO or ASME), ensures reliable performance in various applications.

8. Conclusion

For ultrasonic flow meters, ensuring sufficient straight pipe lengths upstream and downstream is essential for accurate and reliable measurements. By following general guidelines—10D to 20D upstream and 5D to 10D downstream, depending on disturbance levels—users can achieve stable flow profiles that minimize errors. In cases where space is limited or high levels of turbulence are present, flow conditioners can help create a uniform flow profile. Adhering to these best practices allows ultrasonic flow meters to provide precise and consistent readings in a wide range of applications.