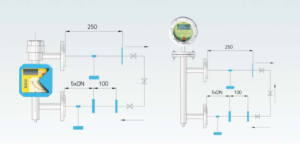

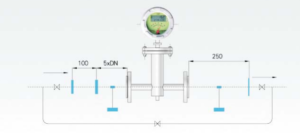

Where:5xDN and 250 are the straight tube section in the front and rear of the flowmeter,100 is the pre-left position for installation of the magnetic filter.

Notices on installation instrument

Before installation of the instrument, the process lines should be blown off to prevent ferromagnetic substances from staying in pipes from adhering to the instrument to affect performances of the instrument or even damage the instrument. If it is unavoidable, a magnetic filter should be installed before the entrance of the instrument. The instrument itself doesn’t take part in the blowing off to avoid damage to the instrument.

Before the instrument is installed in the process lines, all packing should be unpacked to check whether there are damage by transportation. In addition, the shell should be dismantled to take out the filler fixing pointers.

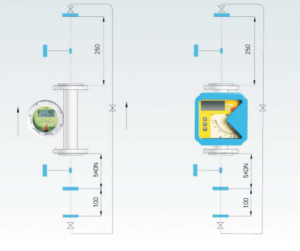

The installation patterns of the instrument are divided into vertical installation and horizontal installation. If the vertical installation pattern is adopted, it should be ensured that the included angle between the central vertical line of the instrument and the plumb line should be smaller than2º. If the horizontal installation pattern is adopted, it should be ensured that the included angle between the horizontally central line of the instrument and the horizontal line should be smaller than 2º

Upstream and downstream pipes of the instrument should have the same bore diameter as the instrument. The connection flanges or screw threads should be matched. It should be ensured that the length of the straight tube upstream of the instrument should be 5 times the bore diameter of the instrument (5D) and the length of the straight tube downstream of the instrument should not be

smaller than 250.

As signals are transmitted through magnetic coupling in the instrument, it is not permitted for ferromagnetic substances to exist within at least ten meters around the installation place in order to ensure the performance of the instrument.

The instrument which is used to measure the flow quantity of gases is calibrated under special pressure. If the gases are discharged into the atmosphere directly at the outlet of the instrument, then a pressure drop will be generated at the rotor and data distortion will be caused. If such operation conditions happen, then a valve should be installed at the outlet of the instrument.

Instruments installed in pipes should not be affected by stress and there should have proper pipe support at the inlet and outlet of the

an instrument so that to make the instrument locate in the minimum stress state.

It should be especially careful in installing the instrument with a PTFE liner. As PTFE will deform under the function of pressure, bolts of the flanges should not be tightened too severely.

For the instrument with LCD, it should avoid that sunshine irradiates the display directly in the installation to that avoid decreasing of the useful life of the liquid crystal.

When measuring low-temperature media, the clamped type flowmeter should be selected.